Metal forming is an important process used in almost all industries such as automobiles, domestic appliances, utensils, aerospace, and numerous others. You have many metal forming technologies like metal forming, rolling machines, sheet metal operations, etc. Next time when you see the body of your car, panels and mudguards of your motorcycle, utensils in your kitchen, remember, they have all undergone metal forming processes.

What is metal forming?

Many metals have the ability to plastic flow in the solid-state when a force is applied to it, and the deformation happens without a significant change in their properties. You can define metal forming as a process that makes metal use its ability to flow plastically under force (pressure) to transform the metal to the required geometrical shape. You can place a metal workpiece in a die cavity and apply suitable pressure to force move the metal into the die cavity.

Metal forming is not a new concept, and it was known to humankind years ago. Our forefathers have witnessed a blacksmith converting the metal to the desired shape (be it a home appliance or a weapon) by hammering it. A goldsmith converts gold into jewelry by following a similar process. The quantum of pressure applied is high, and you will require expensive equipment and tools for metal forming processes. However, since metal forming is a mass-production technique, the cost incurred can be justified.

Read: The Last Guide To Sheet Metal Forming You Will Ever Need.

Read: The Last Guide To Bulk Metal Forming You Will Ever Need.

What happens when you apply pressure on a metal?

When you apply pressure on metal, the metal undergoes various forms of stress. Depending on the pressure/force applied, the metal can undergo stresses, such as uniaxial tension, biaxial tension, tri-axial tension, compression, a combination of tension and compression, shear, etc. You might have seen in a metal testing laboratory how metal behaves during tensile compression and torque loads.

When a metal test piece undergoes a tensile test, there will be neck formation before the metal rod breaks and the same metal buckles on compression load before breaking. You can apply torsion (twisting) load on the metal test piece to see its limits.

You can understand that necking is the limiting factor for tension load and buckling is the limit for compression load. When you design a metal forming component and tools for it, you must consider the limiting factor of the metal to decide the maximum pressure that can apply to deform the metal to the desired form/shape without the occurrence of fracture.

The behavior of metals during forming

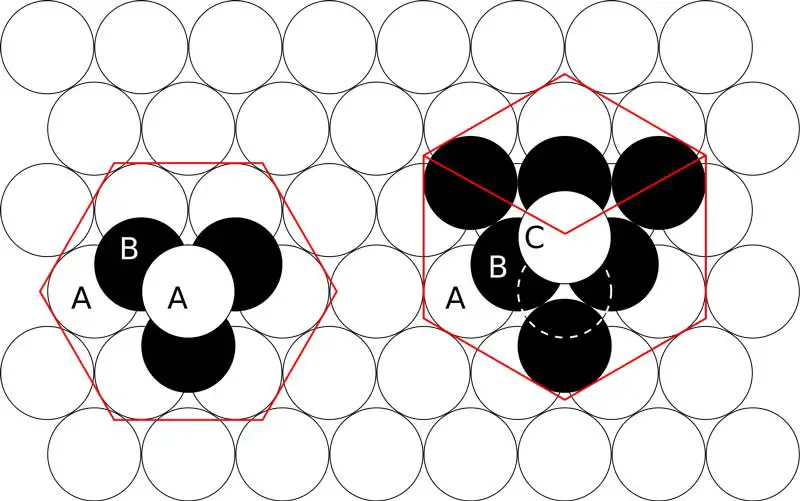

Metal forming is achieved by the permanent deformation of the metal to a desired and valuable shape. The plastic deformation of metals can be explained. Metals comprise numerous irregularly shaped grains of different sizes, and each of the grains has neatly arranged atoms (lattice arrangement). The orientation of the atoms is uniform in an individual grain, but it differs when compared with the adjacent grains.

When you apply pressure on the metal workpiece to deform and change its shape, there will be changes in the grain structure (including fragmentation of grains, distortion in a lattice arrangement, movement of atoms, etc.). The stress-induced by the applied pressure should exceed the elastic limit of the metal to deform it permanently to its new shape.

The metal will be at a more rigid state at room temperature when compared to the same metal at a higher temperature. Due to this, you require higher pressure to deform metal in its cold state than that needed when it is in a hot state. Also, the amount of deformation that metal can undergo in a cold state depends on its ductility.

When you do metal forming in the cold state, recrystallization of grains does not happen, and hence there is no recovery from grain fragmentation or distortion. This leads to a situation called work hardening or strain hardening. In all such cases, the forming process is usually followed by annealing.

Pure metals are more ductile and can undergo better deformation when compared to alloys. Also, metals having larger size grains are more ductile compared to metals with smaller size grains.

Cold, warm, and hot metal forming

Cold, warm, and hot metal forming indicates the state of the metal when it undergoes the forming process. Cold forming indicates the forming of metal at its room temperature, and warm and hot forming indicates forming of metal at its elevated temperature.

A. Cold forming/working

In cold forming, you are doing the plastic deformation of the metal at room temperature (below recrystallization temperature).

Advantages of cold forming:

- No necessity for heating.

- You can achieve a better surface finish and dimensional control, and in many cases, secondary machining is not required.

- Cold-formed components have better repeatability and interchangeability.

- Cold-formed components have better strength, fatigue, and wear properties, and there is no scale formation (since not heated).

Limitations of cold forming:

- Higher pressure (and hence heavier and powerful equipment) is required when compared to warm/hot forming.

- Suitable for high ductile metals only.

- The metals should be clean and free from scales.

- Strain/work hardening is a normal phenomenon and may need immediate annealing.

- There can be undesired residual stresses.

B. Warm forming/working

When you do the metal forming process at a temperature that lies between hot and cold forming, it is called warm working.

Advantages of warm working compared to cold working:

- Lesser pressure on the tool and equipment is required when compared to cold forming. This means less expenditure on the equipment.

- Improved ductility of the metal.

- Fewer chances of work/strain hardening, and hence very few cases require annealing operation.

Advantages of warm working compared to hot working:

- Less amount of heat energy is used.

- Better surface finish, dimensional accuracy, and precision.

- Better tool life due to lesser thermal fatigue and shock on the tooling.

- A lesser amount of scales on the surface.

However, warm working has a disadvantage compared to cold working, since you are spending on heat energy. Besides, the surface finish and dimensional accuracy are inferior compared to cold forming.

C. Hot forming/working

When you do the metal forming (or plastic deformation) process at a temperature above the metal’s recrystallization temperature, it is termed hot working. Due to the pressure applied and the temperature of the metal, the atoms of the metal reach their higher energy level and start the formation of new crystals. This process is known as recrystallization. The new crystals formed due to recrystallization are strain-free, and there is no work/strain hardening.

Advantages of hot working compared to cold working:

- No strain/work hardening, and hence no annealing is required.

- The metal becomes more ductile, and hence higher deformation of the metal is possible.

- You can achieve favorable grain size/grain structure leading to improved mechanical properties.

- The power of the equipment will be less since the force/pressure required is less.

- Hot formed components do not have residual stresses.

Disadvantages/limitations associated with hot working are:

- A high amount of heat energy is required.

- The surface finish is poor due to the scale formation.

- The level of precision, dimensional control, repeatability, and interchangeability are inferior when compared to cold working.

- Extra care and equipment are needed when handling hot components.

- The life of the tools will be less.

Different types of metal forming processes

Metal forming processes are broadly divided into Bulk metal forming and Sheet metal forming processes.

Forging (open die forging, impression die forging, press forging), swaging, radial forging, roll forging, extrusion, ‘wire, rod, and tube’ drawing, and rolling are the Bulk metal forming processes.

Shearing (piercing, blanking, punching, trimming, notching, nibbling, and perforating), bending, drawing, embossing, coining, etc., which mainly involves sheet metal, are called sheet metal operations.

References: