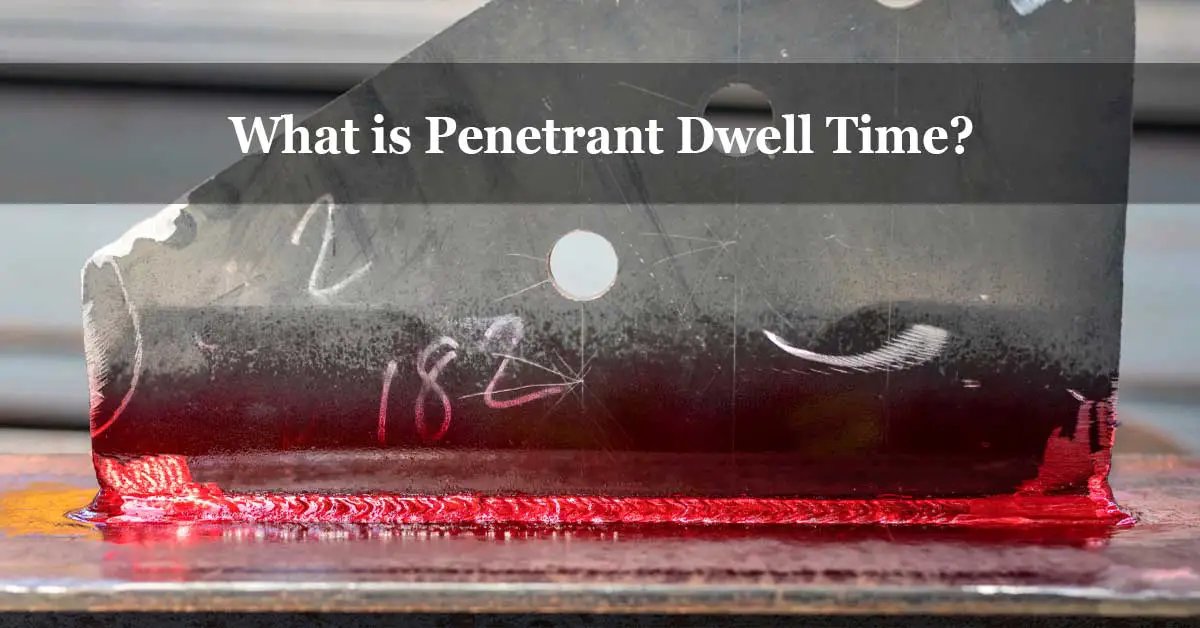

Penetrant dwell time is the period where liquid penetrant remains on the test piece surface before removal. The liquid penetrant remains on the test piece surface for the dwell time to provide sufficient time to seep and fill any openings or voids. The dwell time includes immersion, soak, and drain times.

Various interacting factors affect the dwell time length, such as void size, penetrant sensitivity, test piece form and material, discontinuity type, discontinuity contamination, insoluble contamination, and soluble contamination.

Factors Affecting Penetrant Dwell Time

Void Size

Both widths of the void’s surface opening and depth affect the total time of the liquid penetrant to seep into and fill the void and hence affect the dwell time. The wider the opening, the faster the penetrant can penetrate inside it. The deeper the void, the longer the penetrant takes to fill the void.

Penetrant Sensitivity

The length of penetrant dwell time is affected by the penetrant sensitivity, liquid penetrant surface tension, contact angle, and viscosity, which are different between various penetrant sensitivities and types create differences in dwell time. Therefore, liquid penetrants within each of the sensitivity levels have equivalent dwell time.

Test Piece Form and Material

Test piece form such as castings, forgings, welds, etc., affects penetrant dwell time. For example, forgings discontinuities are usually tighter than castings discontinuities; thus, forgings workpiece usually require more dwell time during the penetrant test.

Test piece material affects dwell time as well. For example, cold shuts openings in steel casting usually are tighter than cold shuts in magnesium castings; thus, steel workpieces usually require more dwell time during the penetrant test than magnesium workpieces.

Discontinuity Type

Discontinuities differ between each other in width and depth; therefore, various discontinuities have different dwell times. In general, the dwell time length increases as the discontinuity width decreases.

Discontinuity Contamination

The amount of contamination entrapped in the discontinuity directly affects the penetrant dwell time. The dwell time provided in any standard is based on a clean workpiece without entrapped contaminants.

Insoluble Contamination

Insoluble contamination inside discontinuities may block penetration from occurring depending on the amount of the contamination. If the discontinuity is full of contamination, the penetrant will completely block from penetrating, and the test cannot be achieved successfully even by increasing dwell time.

If the discontinuity is filled partially by contaminated material, the indication will be less visible or small in size even by increasing dwell time. Therefore, a more sensitive penetrant will produce a more visible indication.

Increasing the dwell time will not improve the results in the case of insoluble contaminations.

Soluble Contamination

Soluble contaminations are the contaminations that can dissolve in the penetrant and affect its penetrating properties. Soluble contaminations are grease, oils, cleaning solutions, and other soluble organic materials.

Upon applying the penetrant on contaminated discontinuity with soluble contamination, the penetrant and the contaminating material will mix. By increasing the dwell time, the pure penetrant will replace the contaminated mixture and improve the indication’s visibility, a more sensitive penetrant will produce a more visible indication.

Increasing the dwell time will improve the results in the case of soluble contaminations.

Penetrant Dwell Modes

Immersion dwell mode and drain dwell mode are the two main penetrant dwell modes.

Immersion Dwell Mode

Immersion dwell mode is performed by keeping the test part submerged in liquid penetrant for the entire dwell time.

Drain Dwell Mode

Immersion dwell mode is performed by covering the test part with penetrant by spraying, brushing, or immersion and then allowing it to drain during the dwell time.

The drain dwell mode provides better performance compared to the immersion dwell mode. Drain dwell mode is more economical as the excess penetrant can drain from the part, recovered, and reused. It is also more economical as the consumption of emulsifier during the penetrant removal process is reduced; the same is due to the thinner penetrant layer remains on the part after the draining process.

Minimum Penetrant Dwell Time

Minimum dwell time will always be stated in the relevant standard or by the penetrant manufacturer. The minimum dwell time is usually determined based on past experience with a similar part, manufacturing process, materials, and potential defects.

The dwell time will vary based on the ambient temperature conditions during testing. The minimum dwell time should be clearly stated in the testing procure, work instruction, or referred to a specific relevant standard.

Insufficient Dwell Time

When dwell time is insufficient or too short, the penetrant will not completely fill the discontinuity and thus reduce the indications’ visibility.

Insufficient dwell time has various effects on the discontinuity’s visibility based on its size; very small discontinuities will typically not appear, and the test will show no indication. Medium size discontinuities will barely be visible and will be significantly reduced in size. Large size discontinuities indications will slightly reduce visibility.

The part that has not have sufficient dwell time should be thoroughly cleaned and then reprocessed through the entire inspection process.

Excessive Dwell Time

The penetrant should be penetrated entirely into the discontinuities and any surface openings on completion of dwell time. Extending the dwell time will not affect or improve the visibility of the indications.

Excess dwell time will be only useful in the case of contaminated discontinuities with soluble contaminations; the increase in dwell time will allow pure penetrant to replace the contaminated and improve the indications’ visibility. Besides, the application of fresh penetrant improves penetration and makes excess surface penetrant easier to remove at the end of the dwell time.

Related: A Guide To Penetrant Test Classifications.

Reference:

- ASNT Level III Study Guide Liquid Penetrant Testing Method.