Screw threads are a fundamental component of everyday life. They are used in a variety of objects, from screws and bolts to machine parts and electronics. Understanding the basics of screw threads and the different types of threads is essential for any DIYer or professional looking to construct or repair items.

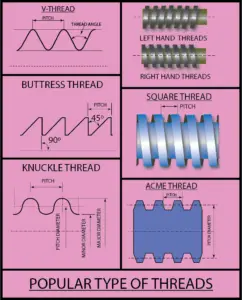

Threads come in different sizes and can have various shapes (e.g., square threads), pitches (distance between each thread), angles (inclination against perpendicular axis), and other characteristics like material grade. Different kinds of finishes can also be added.

The different types of threads

There are many types of threads used worldwide, but let us concentrate on the most used types of threads. The threads can be classified in two ways:

- As per the standards to which the threads conform.

- The physical form of the threads (male or female, left or right hand, etc.).

Types of threads according to the standards to which the threads conform:

The threads can be as per American, British, and ISO Metric Standards.

A. American Standard Threads

1. UNC and UNF

UN stands for unified thread, UNC stands for unified coarse threads, and UNF stands for Unified fine threads. The designation ½-20 UNF 2A indicates it is a unified fine thread with a major diameter of ½ ʺ, 20 threads per inch, 2 indicates the thread class, and A indicates male thread or external thread (B indicates female thread or internal thread). The same unified thread with a major diameter of ½ ʺ can have coarse threads with 13 TPI.

2. NPT (National Pipe Taper or American National Standard Taper Pipe Thread) and NPTF (National Pipe Taper Fuel or Dry seal American Standard Taper Pipe Thread)

NPT threads use taper threads for sealing and are used in every application (a Teflon tape is wound on the tapered thread). NPTF is used for dry seal connections in many applications, specifically for fuel connections.

3. Seller Thread

This type of thread is accepted and recognized by the American Standards Institute, and the thread form is named after an American engineer William Sellers. The thread profile is “V” shaped with a 60º angle and flat roots and crests. The seller thread is used to assemble motor vehicles and airplanes.

B. British Standard Threads

1. British standard pipe (BSP) threads

BSP threads are adopted worldwide for interconnecting pipe and its fittings, except in North America, where NPT (National Pipe Thread Tapered) is used instead of BSP. The thread profile of BSP is similar to BSW (55º angle). The BSP threads can be parallel (BSPP) or taper (BSPT). A combination of parallel female threads (internal threads) and taper male threads (external threads) or taper male and female threads is often used to achieve pressure tightness.

2. British Standard Whitworth threads

The BSW or British Standard Whitworth threads are named after its inventor Sir Joseph Whitworth. The included profile angle is 55º, and both the crest and root have a round shape (radius). BSW types of threads are popular for ordinary fasteners (bolts and nuts).

3. British standard fine (BSF) threads

The thread profile is the same as BSW but with a fine pitch. And this is a fine thread series of BSW. The only difference between BSW and BSF threads is that BSF has more threads per inch.

4. British Association (BA) screw threads

The BA screw threads are used for assembling small instruments and models. The screw thread angle of BA screw threads is 47.5º and can be used for up to 6 mm bolts and their matching nuts.

C. ISO Metric screw threads

ISO (International Organization for Standardization) metric screw threads are adopted in most parts of the world. Metric screw threads have a “V” profile, and the included angle of the “V” is 60º. The root of the thread profile has a radius. Metric thread is designated by its major diameter and pitch diameter (millimeters).

You have both fine and coarse series pitches in ISO metric threads. Viz. M10×1.5 (major diameter 10 mm and pitch 1.5 mm) is a coarse pitch, and M10×1.25 and M10×1 are fine pitches. The metric type of thread can be metric parallel or metric tapered.

D. Other types of threads

1. Square thread

The name comes from its thread profile that resembles a square shape, and the profile has a strong root. Square threads are used to lift heavy loads, screw jacks, lead screws, clamping devices like a vice, and exert pressure. Square threads are designated by their nominal diameter and pitch diameter in millimeters.

2. Acme thread

Acme threads are similar to square threads, but the profile is trapezoidal instead of square. This thread’s profile has a thread angle of 29º. These threads are considered stronger and easier to manufacture than square threads. Acme thread is used for lead screws, and the slanting ends make it easier to screw or unscrew with the split nut.

3. Buttress thread

Buttress thread is also called saw tooth thread due to its resemblance in appearance. The thread profile is triangular, but one side of the triangle is at a right angle to the screw axis, and the other side is sloped. The asymmetric thread profile helps the thread to have less friction and the ability to withstand more load (compared to other thread forms) in one direction. But this comes at the cost of high friction and lower load-bearing in the reverse direction. This form of the screw can provide the higher pull required on one end.

4. Worm thread

Worm thread has a profile similar to acme threads. But, a worm thread is normally called a worm and meshes with a worm gear to transmit motion at an angle of 90 degrees.

5. Knuckle thread

Knuckle threads are sometimes called round threads due to their good round-shaped crests and roots. The wide space between the round crests and roots accommodates debris without interfering with the screw thread; hence, it is known as debris resistant.

DIN standards cover knuckle thread profiles with 30º flank thread angles, which are specified by threads per inch. Knuckle threads are used for lead screws with plastic sliding nuts, bulbs with thread ends, and stainless steel fittings for interconnecting different pipelines in a milk dairy, chemical, and pharmaceutical factory.

The Physical Form of the Threads

Based on this, the threads can be left-hand or right-hand threads, parallel or taper threads, V profile threads, and single or multi-start threads.

1. Left-hand Threads

The threads inclined towards the left are referred to as left-hand threads. Unlike a regular right-hand threaded screw, a left-hand threaded screw tightens or moves forward when turned in the anticlockwise or counterclockwise direction. Left-hand threads are highly useful for specific applications.

2. Right-hand Threads

In the case of right-hand threads, the threads are inclined towards the right. Right-hand threaded screws find their application everywhere. A right-hand threaded screw gets tightened or moves forward when turned in the clockwise direction.

3. Parallel Threads

Parallel threads have the same diameter between the crests, all over the length.

4. Taper Threads

Taper threads are threads cut on a tapered surface, and the dimensions between the crests of the thread will be different at the beginning and the end of the threads. The taper threads can be left or right-hand threads.

Taper threads are used for specific machine assemblies to get leverage for lifting weights, precision measuring instruments, etc.

5. V profile Threads

In this case, the thread profile resembles the alphabet “V,” and it is used in threads of various standards. However, the included angle of the “V” can be different in different standards of threads.

6. Single-start and multi-start Threads

The threads can be single-start or multiple-starts (two-start, three-start, etc.). A multi-start thread will have more than one tangled thread cut parallel. However, the pitch of the threads will remain the same.

In a single-start thread, one revolution of the thread results in movement of the thread by one pitch; however, in a two-start thread, the movement per revolution will be two times the pitch. In a three-start thread, the movement per revolution will be thrice the pitch, and so on.

7. Self-tapping and self-drilling type screws

Finally, the screws (a popular form of fastener) can be self-tapping type screws and self-drilling type screws. You can use a self-tapping screw to assemble two sheets (a panel cover with the thin frame of a machine). In this case, the panel cover will have a hole to guide the screw, and the machine frame will have a small punch. The self-tapping screw creates the threads as it digs into the machine frame.

The self-drilling screws are used under similar circumstances, but the machine frame will be much thicker. The self-drilling screw makes a drill and creates the thread progressively as it digs into the metal.

How do you identify the type of threads and its size?

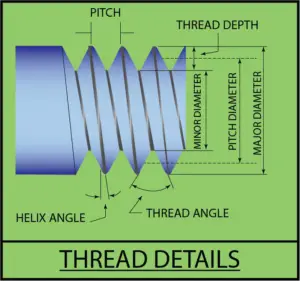

Threads are a form of grooves formed on a male or female diameter in the form of a continuous helix. If you want to identify the threads on a part, you must be aware of the following:

- Type of threads (briefly explained in the previous paragraphs).

- Different dimensions of a thread.

- Instruments to measure the threads.

Different dimensions of a thread

The major diameter of the threaded part is the largest thread diameter and is measured across the topmost portions of the thread profile (crest). The smallest thread diameter is called the minor diameter, and it is measured between the roots of the thread. The pitch diameter is an imaginary diameter between the major and minor diameter, and at this point, the thread’s width and the grove’s width will measure the same.

The pitch is the distance between the two same points on a thread (between two crests), and they can be designated in two ways, threads per inch (TPI) (as in most American and many British Standards) or millimeters (ISO metric standard).

The TPI or pitch diameter in millimeters indicates how close or far the threads are from one another. You can have a screw with the same major diameter but different pitches.

Instruments to measure the threads

1. Pitch gauge

A pitch gauge is a set of sheet metal with continuous thread profiles of different standards cut on it, and each sheet has a marking to indicate which type of thread it is. You can match the actual threads with the different pitch gauges till you find a perfect match, and the marking on the pitch gauge tells you which thread it is. In the case of UN, NPT, and BSP threads, it will tell you the threads per inch (TPI), and metric threads will tell you the pitch in millimeters.

2. Vernier caliper

You can use a Vernier caliper to measure an object’s outside and inside dimensions, and there are Vernier calipers that give a digital readout. You can use this to measure the major diameter of a male thread (outer diameter) or a female thread (inner diameter).

How to identify the types of threads

Examine the threaded part and follow the steps below to identify the thread.

Step 1

The thread can be male (external thread) or female (internal thread); for example, a bolt has a male thread, and a nut has a female thread.

Step 2

Verify if the threads are metric tapered or metric parallel. The major diameter of the parallel threads remains the same throughout the length of the thread. Use Vernier calipers and measure the major diameter of the first, fourth, and last full thread. If the diameter size increases on a male thread or decreases on a female thread, then it is a tapered thread.

The taper threads can be of different standards like NPT or NPTF, BSPT, and metric tapered threads.

Step 3

Use a pitch gauge to compare and know the pitch. The pitch size can be threaded per inch or in millimeters. Compare the threads with a pitch gauge till you find a perfect match, and note down the pitch size. Do this with patience.

Step 4

Measure the nominal major diameter of the male (outer diameter) or female thread (inner diameter). Use your Vernier calipers and measure the dimension between two crests. For tapered thread, measure the 4th or 5th full thread; for parallel threads, measure any full thread.

Step 5

Compile all the data you have collected about the threaded part and note it down on a sheet of paper. Compare the compiled details with the charts of different thread standards. You will find all the standards online; many websites allow you to download them in PDF format. You have to allow for little variation in the dimension due to manufacturing deviations or wear out.

Knowing the place of manufacturing of the part under scrutiny can help you to identify the thread size and type of screw thread. If unsure, contact the manufacturer’s helpline and share the details; they will help you.

Conclusion

In the above paragraphs, we have discussed the different types of threads and how to identify a screw thread of a threaded part. Hopefully, now you are armed with sufficient details to identify the threads of any part of your appliance or machine.

Reference: