Pumps are mechanical equipment used in various industrial applications to transport fluids by increasing their pressure. Whether you are looking for a pump for your home or your business, you must familiarize yourself with the different types of pumps and understand how they work to select the best option for your needs.

This article will provide an overview of pumps and their various uses, outlining each type in detail and its components and features. We will also discuss typical applications where these pumps can be employed effectively. Read on to learn more about this essential technology!

How to select the suitable pump?

The right pump for a specific application is crucial for efficient fluid handling. There are several factors to consider when choosing a pump. Here is what you need to know about selecting the appropriate pump for your application.

1. Type of Fluid: The fluid’s characteristics are one of the most critical factors to consider when choosing a pump. The fluid’s viscosity, corrosiveness, temperature, and solid content will determine the type of pump required. For example, centrifugal pumps are ideal for thin liquids, while positive displacement pumps work best for thicker and more viscous fluids such as syrups, adhesives, and oils.

2. Amount of Fluid: The volume or amount of fluid pumped is another critical factor to consider. Some pumps, such as axial flow and centrifugal pumps, are suitable for handling large fluid volumes. On the other hand, positive displacement or metering pumps may be better suited for applications requiring precise amounts of fluid to be moved, such as dosing applications.

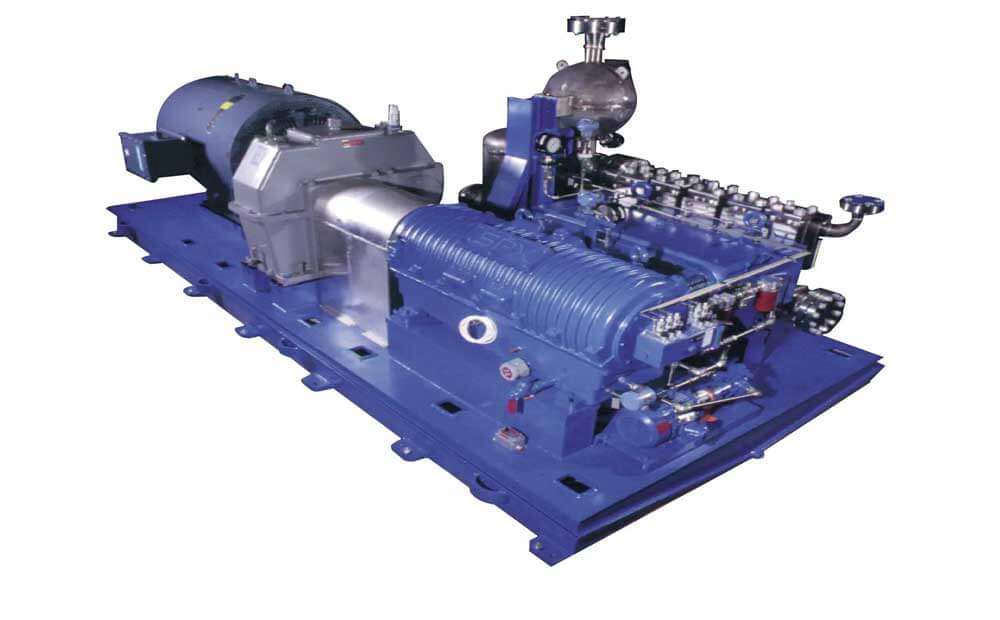

3. Distance: The distance the fluid must be transported is another critical factor determining the pump required. Some pumps have limited head pressure and may not be suitable for pumping fluids over long distances. In contrast, pumps with high head pressure, such as multi-stage pumps, can move fluid over considerable distances.

4. Pump Capacity: Pump capacity refers to the amount of fluid a pump can move per unit of time. Choosing a pump with the appropriate capacity for your application is essential to avoid overloading or underutilizing the pump. The best way to determine the required pump capacity is to calculate the flow rate needed to achieve the desired output.

5. Efficiency: Pump efficiency is essential to consider as it will impact the operational and maintenance cost. Higher-efficiency pumps will cost more initially, but they will save you money in the long run as they consume less energy and require less maintenance. Low-efficiency pumps may save you money at the front end, but they will consume more energy, increasing operational costs.

Pump types for specific applications

Below are some of the suitable pump types for specific applications:

1. Centrifugal Pumps: Suitable for applications that require efficient handling of large volumes of thin fluids, such as water, chemicals, and light oils.

2. Positive Displacement Pumps: Ideal for applications that require the handling of thicker or more viscous fluids, such as syrups, adhesives, oils, and paints.

3. Axial Flow Pumps: Suitable for applications that require the movement of large volumes of fluids at low to moderate head pressures, such as irrigation systems, cooling water, and flood control systems.

4. Multi-Stage Pumps: Suitable for applications that require moving a large volume of fluids over long distances with high head pressure, such as water distribution systems and high-rise buildings.

5. Diaphragm Pumps: Ideal for applications that require high precision, continuous flow, and handling of corrosive fluids, such as in paint and ink dispensers, fuel transfer, and pharmaceutical processing.

6. Peristaltic Pumps: Suitable for applications that require high accuracy and handling of shear-sensitive or abrasive fluids, such as bioprocessing, chemical metering, dispensing, and food processing.

Types of Pumps (Classification of Pumps)

Pumps are essential in various industries and applications, from transferring fluids to powering large machines. There are two primary categories of pumps: Rotodynamic Pumps (Kinetic) and Positive Displacement Pumps.

Rotodynamic pumps transfer fluid using rotating mechanisms to create kinetic energy in the fluid, which increases the fluid’s potential energy. Centrifugal pumps are one of the most commonly used subcategories of rotodynamic pumps and mixed flow and axial flow pumps. These pumps are better suited for handling fluids with lower viscosity and solids content.

Positive displacement pumps, on the other hand, generate flow by trapping a specific volume of fluid and then forcing it through the pump discharge. Common positive displacement pumps include reciprocating pumps, such as piston and diaphragm pumps, and rotary pumps, such as gear and lobe pumps. Positive displacement pumps are ideal for handling viscous liquids or liquids with higher levels of suspended solids.

Dynamic Pumps

Dynamic pumps are a type of pump that transfer fluid using rotating mechanisms to create kinetic energy in the fluid, which increases the fluid’s potential energy. These pumps are typically used for applications that require a wide range of flow rates and discharge pressures and are ideal for handling fluids with lower viscosity and solids content.

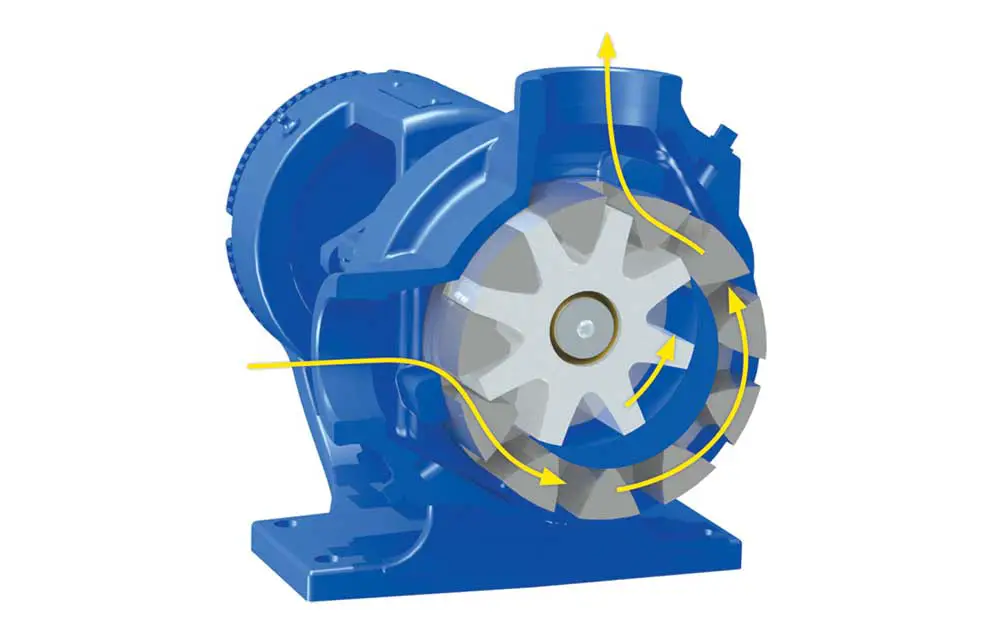

Centrifugal Pumps

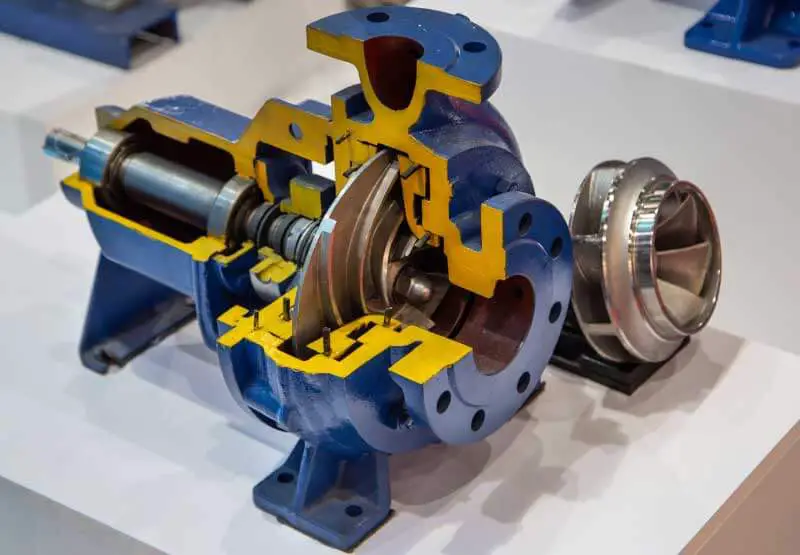

A centrifugal pump is mechanical equipment that uses a rotating impeller to transfer fluid through a series of vanes known as diffuser casings. The impeller creates a centrifugal force that propels the fluid outward towards the diffuser casing, which converts the kinetic energy into potential energy and increases the fluid’s pressure.

The operation cycle of a centrifugal pump involves several stages. First, the fluid enters through the pump inlet into the impeller’s eye or center, picking up speed and kinetic energy. The rotating impeller propels the fluid towards the diffuser casing, where the kinetic energy is converted into potential energy, causing a pressure increase. Finally, the fluid exits the casing through the pump volute and discharges into the delivery pipe.

Centrifugal pumps come in different types, including axial, radial, and mixed-flow impellers. An axial flow impeller moves the fluid parallel to its axis of rotation, resulting in a high flow rate but low pressure. A radial flow impeller moves the fluid perpendicular to its axis of rotation, producing a moderate flow rate and moderate pressure. A mixed-flow impeller generates axial and radial flows, delivering higher flow rates and pressures.

Horizontal Centrifugal Pumps

A horizontal centrifugal pump is made up of various components, including a pump casing, impellers, a shaft, bearings, and a motor. The impellers, typically two or more, are mounted onto the same shaft and rotate in opposite directions.

When the pump operates, the impellers spin at high speeds, generating a centrifugal force. This centrifugal force causes the fluid to move toward the outer edge of the impeller, where it gains kinetic energy. As the fluid moves through the impellers, it picks up more speed and kinetic energy, increasing fluid pressure.

The horizontal centrifugal pump is essential in a wide range of pumping services. It is commonly used in companies that transfer large amounts of industrial fluids such as water, oil, and chemicals. Its capacity to handle high flow rates and generate sufficient pressure makes it an ideal choice in such applications.

Vertical Centrifugal Pumps

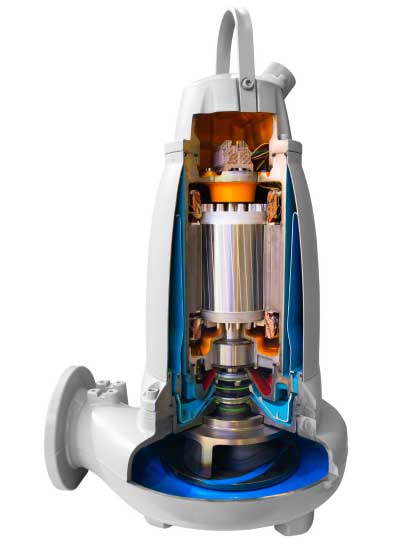

Vertical centrifugal pumps are a unique type of dynamic pump with distinct design and maintenance features that set them apart from other centrifugal pumps. The pump’s vertical orientation and cantilevered shaft and bearing design make them particularly useful in applications where the volume needs to flow into a pit.

One of the most notable features of a vertical centrifugal pump is its cantilevered shaft, which is securely mounted on top of the pump casing. This unique shaft and bearing design helps the pump to operate with minimal maintenance, as there are no bearings or bushings to maintain or lubricate. Additionally, this design makes the pump ideal for use in applications with limited installation space or where maintenance access is difficult.

These pumps are commonly used in applications where volume flow needs to be directed into a pit or sump. Their vertical design and cantilevered shaft make them particularly suitable for this task, as they can be easily installed and mounted above the pit without the need for complex piping or additional pumps. Vertical centrifugal pumps are also commonly used in industrial applications such as chemical processing, power generation, and water treatment, where the efficient transfer of fluids is critical for the operation’s success.

Advantages of Centrifugal Pumps

Simple Design: One of the primary advantages of centrifugal pumps is their simple design. They consist of just a few basic parts, which makes them easy to manufacture and repair. This simple design also contributes to their low cost, making them an affordable option for many businesses.

Strength And Efficiency: Centrifugal pumps are also known for their strength and efficiency. They can handle high flow rates and are excellent for pumping large volumes of fluid quickly and efficiently. Additionally, centrifugal pumps have reduced friction, contributing to their durability and longevity.

Corrosion Resistance: Centrifugal pumps are also known for their corrosion resistance. This makes them ideal for use in corrosive environments such as chemical plants and wastewater treatment facilities. They can withstand harsh chemicals and fluids without experiencing wear and tear.

Energy Efficiency: centrifugal pumps have excellent energy efficiency. They require less power to operate than other pumps, which can result in significant energy savings. They also offer a smooth fluid flow, contributing to their efficiency.

Reliability: centrifugal pumps have a proven track record of dependable performance. They require minimal maintenance and can operate for extended periods without needing repairs.

Versatile And Practical Choice: centrifugal pumps come in various sizes and can be used in various applications, making them a versatile and practical choice for businesses.

Disadvantages of Centrifugal Pumps

While centrifugal pumps have many advantages, there are a few disadvantages to consider before choosing this type of pump for a specific application.

Poor Suction Power: One significant disadvantage of centrifugal pumps is their poor suction power. They are not effective at drawing in fluid from a distance or lifting fluids from a lower level, limiting their use in certain applications.

Extremely Corrosive Environments: While they are known for being corrosion-resistant, they may not be suitable for extremely corrosive environments. Over time, corrosion can cause damage to the pump and lead to costly repairs.

Viscous Fluids: Centrifugal pumps may struggle with viscous fluids. They are designed to handle fluids with low viscosity and can become less efficient when pumping thicker liquids such as oils or slurries.

Excessive wear: operational wear is another potential issue with centrifugal pumps. The prolonged and consistent use of centrifugal pumps in certain applications can lead to excessive wear and tear on the impellers, casings, and other components.

Power-Hungry: centrifugal pumps can be relatively power-hungry. They require more power to operate than positive displacement pumps, which can increase operating costs over time.

Positive Displacement Pumps

Positive displacement pumps are a widely used type of pump designed to mechanically displace fluid and increase the pressure within a system. Unlike centrifugal pumps, positive displacement pumps can handle viscous liquids, making them perfect for applications where high-viscosity liquids, such as oils, must be moved.

1. Reciprocating Pumps

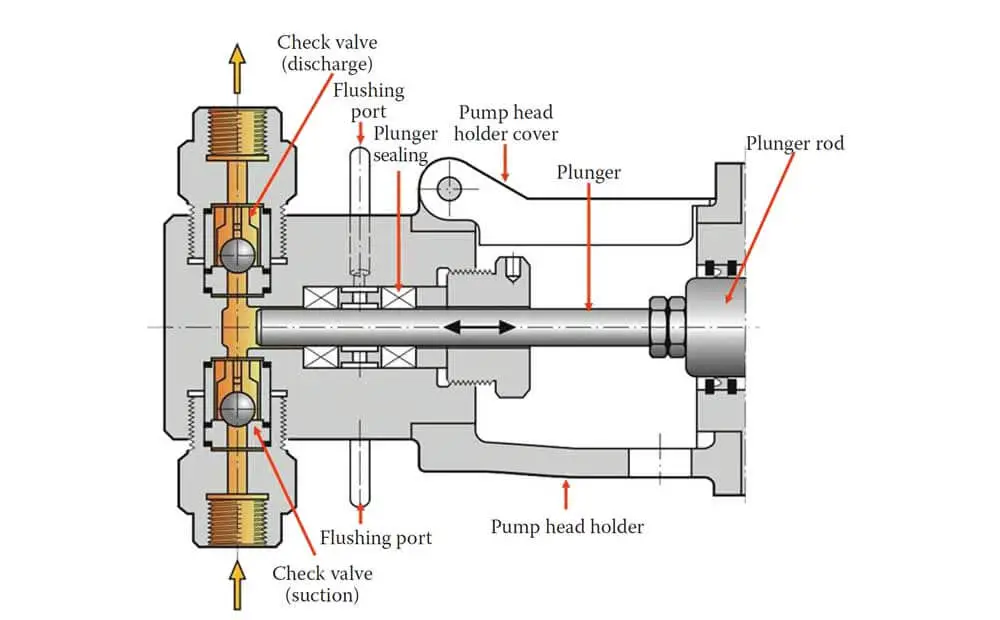

A Reciprocating Pump is a positive displacement pump that uses a plunger or membrane to create a pressure difference through a fluid. This pump operates by a reciprocating action of the plunger or membrane in the pump chamber, which helps draw in and expel the fluid. The repetitive back-and-forth movement of the plunger characterizes its working mechanism.

The Reciprocating Pump comes in three main types– Simplex, Duplex, and Triplex. The primary difference is the number of plungers or membranes present in the pump. Simplex pumps contain one plunger or membrane, duplex pumps use two, and triplex pumps have three.

Reciprocating pumps find applications in several industrial settings, especially where viscous fluids are involved, and well-controlled low-flow rates are required. The pump can operate manually or by an engine drive based on its intended use.

1.1 Plunger / Piston Type of Reciprocating Pumps

The plunger (or piston) type of reciprocating pump is a positive displacement pump widely used in various industrial applications, specifically where viscosity is a concern. Its working principle is based on a reciprocating motion of a plunger or piston inside a cylinder that creates a vacuum at the inlet and pressure at the outlet resulting in continuous fluid flow.

The plunger/piston moves back and forth within the pump cylinder, creating a vacuum during the up-stroke and drawing in fluid through the inlet valve at the bottom of the cylinder. During the down-stroke, the plunger/piston pushes the fluid through the outlet valve at the top of the cylinder, discharging it to the desired location.

One advantage of this type of pump is that it is suitable for handling viscous liquids and can deliver constant flow rates, which makes it ideal for metering applications. They also can deliver high pressures, making them ideal for various industries such as oil and gas, chemical, and water treatment.

Despite their advantages, plunger/piston pumps can have limitations concerning their higher maintenance requirements due to their mechanical components. However, proper maintenance and care can lead to a long lifespan for this pump type.

1.2 Diaphragm Pumps

A diaphragm pump is a positive displacement pump that utilizes oscillating diaphragms to move liquid. Unlike plunger pumps, the diaphragm pump has two chambers separated by a flexible diaphragm made of rubber, Teflon, or thermoplastic. This design allows the liquid intake to one chamber while the other chamber is in the discharge phase, creating a pulsed liquid flow.

Diaphragm pumps are commonly used in industries where dangerous fluids need to be handled, as the flexible diaphragm separates the fluid being handled from the pump’s mechanical components, preventing contamination or leakage. They are also suitable for handling viscous fluids.

Diaphragm pumps offer several advantages over other pump designs. They have a simple and reliable construction, which allows them to be easily maintained and operated by individuals with basic technical knowledge. They are also designed to handle various liquids, from acids and bases to adhesives and viscous substances.

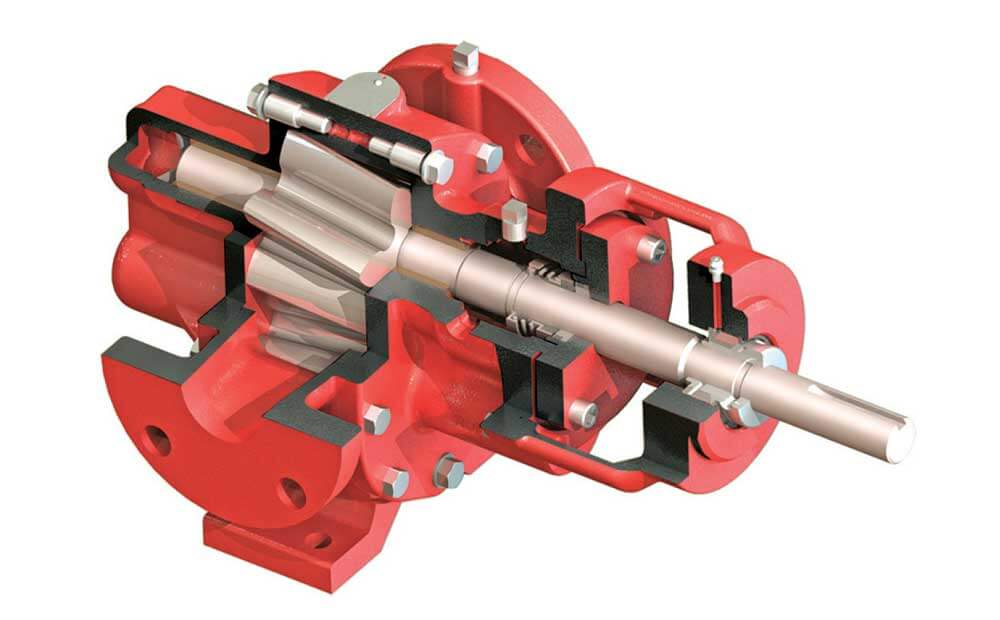

2. Rotary Pumps

Rotary pumps are positive displacement pumps that use a rotating element to transfer fluid from the inlet to the outlet by creating a fluid pressure gradient. Unlike other types of pumps, which use mechanical action to increase the pressure of the fluid, rotary pumps rely on the displacement of a fixed volume of fluid per rotation.

The design of a rotary pump typically consists of a pump casing, a rotating element, and a shaft that connects to a motor. The pump casing contains the inlet and outlet ports, and the rotating element creates fluid displacement. The rotating element is typically a geared rotor that rotates on a fixed axis and sits inside the pump casing. As the rotor turns, fluid is drawn into the pump casing through the inlet port and displaced by the rotor as it moves toward the outlet port.

Rotary pumps are often used for high-viscosity fluids, such as oils, syrups, and polymers, due to their efficiency in moving these fluids. They can also generate high pressure with a low flow rate, making them suitable for applications requiring precise flow control. Compared to other types of pumps, rotary pumps are known for their reliability and long life span due to their simple design and minimal moving parts.

Several types of rotary pumps include gear pumps, vane pumps, and screw pumps. Gear pumps use two interlocking gears to create fluid displacement, while vane pumps use blades that slide in and out of the rotor to create fluid flow. Screw pumps use two or more helical rotors that generate fluid displacement by rotating in opposite directions.

2.1 Gear Pumps

Gear pumps are positive displacement pumps that utilize interlocking gears to create fluid flow. The pump typically consists of a pump casing, two gears (an idler gear and a drive gear), and a shaft that connects to a motor. The gears have specifically designed teeth that mesh together, creating small pockets that move fluid from the inlet port to the outlet port.

Unlike dynamic pumps, such as centrifugal pumps, which move fluids using kinetic energy, gear pumps move fluids using the mechanical energy created by the rotation of the gears. This makes it a suitable choice for applications requiring a constant flow rate, such as in transferring thick liquids like fuel, grease, and oil.

There are two types of gear pumps: external and internal gear pumps. External gear pumps have two identical gears that rotate in opposite directions, where the fluid is drawn in between the teeth of the gears and the casing, then expelled out the other side.

On the other hand, internal gear pumps have an inner gear that drives the outer gear, which rotates in the opposite direction. The fluid is drawn between the gears’ teeth and the casing and then expelled from the pump.

External gear pumps are commonly used in industrial applications. In contrast, internal gear pumps are generally utilized in more specialized or precision applications, such as metering fluids or handling abrasive and viscous materials.

2.2 Rotary Lobe Pumps

Rotary Lobe Pumps are considered the most efficient type of rotary pump. They are designed to handle high-viscosity fluids and do not cause erosion, making them perfect for transferring delicate fluids. Furthermore, their gentle and pulsation-free operation makes them suitable for biotechnological and pharmaceutical applications.

A Rotary Lobe Pump operates using two or more rotating lobes which intermesh within a pump chamber. The lobes have a s shape, and they rotate in opposite directions. The fluid is drawn into the pump chamber, trapped between the lobes and the pump casing. As the lobes rotate, the fluid is transported from the inlet to the outlet side of the pump.

The Rotary Lobe Pump’s design allows it to easily handle fluids with varying viscosities, including those with high viscosity that would typically damage other types of pumps. The lobes intermesh, so the pumping velocity remains constant, enabling it to pump fluids steadily.

Advantages of Positive Displacement Pumps

Positive Displacement Pumps (PDP) are commonly used in industrial applications due to their unique advantages.

Delivering High-Viscosity Fluids: Positive Displacement Pumps move fluid by trapping a fixed amount and forcing it through the pump using mechanical action. This means that PDPs are ideal for delivering high-viscosity fluids, liquids containing solids, and applications requiring a constant flow rate.

High Efficiency: One of the biggest advantages of PDPs is their high efficiency. Rotary Positive Displacement Pumps and Reciprocating Positive Displacement Pumps offer efficient and reliable pumping solutions.

Various Applications: Reciprocating Positive Displacement Pumps work by reciprocating a piston or diaphragm to move fluid through the pump. These pumps are known for their precise and accurate flow rates and are often used in applications requiring metering or dosing of fluids. They are also commonly used in high-pressure applications such as hydraulic testing or water jet-cutting machines.

Handling Fluids Containing Solids: Another advantage of PDPs is their ability to handle fluids containing solids without damage. For example, Progressive Cavity Pumps (PDP) can transfer fluids containing solid particles up to 90% of their volume without damaging the pump.

Wide Range of Fluid Pressures: PDPs can operate over a wide range of fluid pressures, meaning they can handle various pumping requirements.

Minimal Maintenance: PDPs require minimal maintenance compared to dynamic pumps, as they do not have impellers or bearings requiring regular replacement.

Disadvantages of Positive Displacement Pumps

While Positive Displacement Pumps (PDPs) offer many advantages, some downsides must be considered before using them for a specific application.

Variation In Flow Rate: One of the main limitations of PDPs is their inability to handle variation in flow rate. Unlike dynamic pumps, PDPs have a fixed displacement, so they can only pump a particular fluid volume per cycle. As a result, they are not ideal for applications that require variable flow rates or where the flow rate changes suddenly.

Inability To Run Dry: When pumping dry, the PDPs will experience rapid wear and tear, which can lead to premature failure. Therefore, ensuring that the pump is always primed with fluid before starting is essential.

Easily Blocked: Another potential disadvantage of PDPs is that they can become blocked quickly if exposed to high solid content fluid. As a result, it is essential to have proper filtration systems in place to prevent blockages that may lead to pump damage.

Frequent Maintenance: PDPs may require more maintenance than dynamic pumps, especially if exposed to harsh fluids or high-solids content. Seals and other components may require more frequent replacement, leading to higher maintenance costs.

Frequently Asked Questions

Here are some frequently asked questions about pumps:

What are the different types of pumps used in industrial applications?

Several different types of pumps are used in industrial applications, each with unique features and benefits. Centrifugal pumps and positive displacement pumps are the most common pumps in industrial applications.

How do centrifugal pumps differ from positive displacement pumps?

Centrifugal and positive displacement pumps are two types used for moving fluids. The main difference between these two types of pumps is their mechanism of action. Centrifugal pumps use a rotating impeller to create a flow of liquid, while positive displacement pumps use a mechanical means to move a fixed amount of fluid with each stroke or rotation.

Which type of pump is best suited for handling viscous fluids?

Positive displacement pumps are best suited for handling viscous fluids. Positive displacement pumps use a mechanism to trap and move the fluid. This makes them ideal for handling thick and sticky fluids, such as oils, syrups, and adhesives.

How do you determine the right type of pump for a specific application?

Determining the right type of pump for a specific application requires careful consideration of several factors. First, it is important to understand the fluid being pumped, including its viscosity, temperature, and chemical composition. Next, the application’s flow rate and pressure requirements must be considered. Other factors are the size and shape of the system, as well as any space restrictions.

What are the types of centrifugal pumps?

Centrifugal pumps can be classified into several types based on their stages, impeller design, and application. End-suction, inline, split-case, and multistage pumps are the most common types.

What are the applications of centrifugal pumps?

Centrifugal pumps are widely used in various industries, including water treatment, HVAC, chemical processing, food and beverage, and oil and gas. They are suitable for handling fluids with low or high viscosity, corrosive or abrasive properties, and clean or dirty conditions.

What are the advantages of centrifugal pumps?

Centrifugal pumps have several pros, including high flow rates, low maintenance, easy installation, and efficient operation. They can handle large volumes of liquid with minimal pulsation and operate at high discharge pressures.

What are the disadvantages of centrifugal pumps?

Centrifugal pumps also have some cons, such as limited suction lift, inability to handle solids or viscous fluids, and cavitation at low inlet pressures. They can also be less effective when delivering precision metering or working with fluctuating flow rates.

Conclusion

In conclusion, choosing the right type of pump for your specific application is crucial for achieving efficient and reliable fluid transfer. Whether you need a centrifugal pump, positive displacement pump, diaphragm pump, or any other type, it’s essential to consider factors such as your fluid properties, flow rate, head pressure, and other requirements.

Always consult with a pump expert to ensure you make the right choice and achieve optimal performance and longevity from your pump. With careful consideration and proper maintenance, your pump can provide years of reliable service across various industrial and commercial applications.

References:

- Pump Characteristics and Applications, Third Edition, By Michael Volk.