You can say that the shielded metal arc welding (SMAW) process is with us for a sufficiently long time. The process of stick welding was invented by Nikolay Slavyanov, a Russian inventor who in 1888 introduced arc welding with consumable metal electrodes; the process was envisaged with a bare metal electrode without a flux coating. The coated welding electrode was developed in early 1900. The shielded metal arc welding (SMAW) process uses a flux coated electrode is popular due to its simplicity to learn and use.

This article will take you through the following topics: what is Shielded Metal Arc Welding/Manual Metal Arc, SMAW process equipment, SMAW process electrodes, applications of SMAW process, advantages and limitations of SMAW, GMAW VS SMAW, and safety considerations.

What is Shielded Metal Arc Welding (Stick Welding)?

Shielded metal arc welding (SMAW) is also known by the names manual metal arc welding (MMA or MMAW), stick welding (slang phrase), or flux shielded arc welding, and this is a manual welding process. SMAW welding process uses a consumable metallic electrode (coated with flux), and the composition of the electrode is based on the workpiece metal composition.

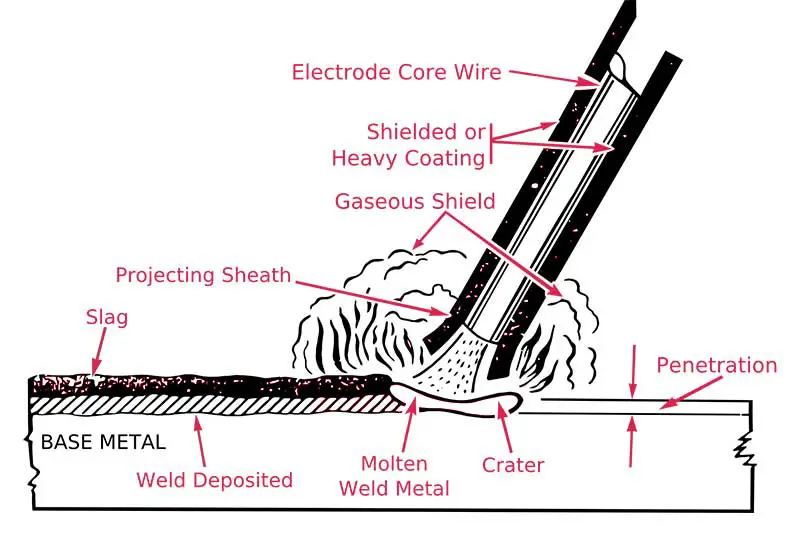

The shielded metal arc welding (SMAW) uses DC or AC electric current to strike an arc between a flux-coated consumable electrode and the workpiece. Due to the high temperature of the arc, the electrode and the workpiece (welding area) melts, and the molten weld pool becomes a weld joint on cooling. When the welding electrode melts, the flux coating on the electrode also melts (disintegrates) and gives off shielding gases to protect the weld area from oxidation due to the oxygen and other gases in the atmospheric air. In addition to this, the molten flux forms a slag on the weld joint to protect it from contamination and fast cooling. The flux, apart from shielding the arc and the weld pool, cleans the metal surface.

The welding operator brings the welding electrode near the workpiece and lightly touches it to strike the electric arc. Once the arc is initiated, the welding rod is pulled back a little allowing the melting of the workpiece area and the consumable electrode. The molten droplets from the electrode fall into the molten weld pool, and this weld pool will become the weld joint after cooling.

The welder chips off the slag and cleans the weld with a wire brush after the welding is completed. When the welding electrode becomes short, the welder stops welding and resumes again after inserting a new electrode in the electrode holder. Stick welding is a manual welding process, and the time spent by the welder on changing the electrode and chipping/cleaning off the slag makes it a slow and least efficient welding process.

Striking the arc is a skill, and a welder needs to master it for different combinations of workpiece and electrode material. The position of the welding rod with respect to the workpiece and its angle of inclination matters when striking an arc.

Stick welding process is used to weld iron, steel, and stainless steel; however, you can use this process to weld nonferrous metals like aluminum and copper alloys. Usually, the composition of the electrode is better than the workpiece material since this improves the weld quality. However, an electrode having the same composition as the workpiece material can also be used. Based on the experience, many combinations, like using a stainless steel welding electrode for welding two workpieces of carbon steel or welding one workpiece of stainless steel with another workpiece of carbon steel, are used.

SMAW process does not use complicated equipment, and the operation is relatively easy and versatile. These qualities make SMAW a popular welding process for doing maintenance and repairs, construction of light and heavy steel structures, and fabrication. Stick welding on flat workpieces is easy to master compared to welding workpieces in the vertical position, or an angle, or at the overhead position. For welding in a vertical/overhead position, the welder needs to choose a welding electrode that solidifies relatively quickly to avoid the molten weld pool from flowing down. However, the electrode that solidifies quickly takes more time to melt, leading to increased welding time.

Quality issues in the Stick welding process

Different quality issues or welding defects are associated with the SMAW process, such as porosity, cracks, weld spatter, incomplete or poor fusion, shallow penetration, etc. While defects like weld spatter affect only the aesthetics (which can be corrected by secondary operations), other defects affect the performance and life of the part.

| No. | Welding defect | The possible reason for the defect |

| 1 | Weld spatter | Very high current, long welding arc, etc. |

| 2 | Porosity (to be detected using nondestructive testing methods). Porosity makes the weld joint weak. | Porosity may happen when the gases released by the flux coating on the electrode and the slag on the weld fails to protect it. Due to this the weld pool/bead absorbs nitrogen, hydrogen, and oxygen from the atmospheric air. The gas molecules are released during the cooling of the weld bead, resulting in porosity. |

| 3 | Incomplete or poor fusion of the weld joint. This makes the weld weak. | Low current or presence of contaminations. |

| 4 | Shallow penetration. | Faster welding speed, low current, etc. |

| 5 | Welding cracks. | Welding of high carbon steel or Sulphur content in the metal may lead to cracking. Welding techniques like proper preheating of the workpiece and proper composition of the electrode may help minimize this defect. |

Welding current

The current operating level depends on the size of the electrodes, and usually, the welding electrode manufacturers mention their recommended operating range of current on the box. The general thumb rule is 40 Amps per mm diameter, and hence the current requirement for a 3 mm diameter welding electrode could be 120 Amps. Still, the electrode manufacturers may mention a range like 100 to 140 Amps.

Types of electric connections in SMAW (polarity)

The direct current electrode negative (DCEN) method causes building up of the heat in the electrode, higher rate of electrode melting, and lesser depth of the weld. The direct current electrode positive (DCEP) method causes an increase in weld penetration. When alternating current (AC) is used, it gives a heat distribution that balances the electrode melting rate and penetration.

Gravity arc welding

Typically, the SMAW process is done manually; however, some methods make SMAW a semiautomatic process. One such method is Gravity arc welding. Gravity arc welding uses an electrode holder fixed to an inclined bar which moves along the weld length.

Once initiated, the gravity arc welding continues till the welding electrode is consumed and starts again when the welder fixes a new electrode. Gravity arc welding uses higher-length electrodes. As in SMAW, gravity arc welding uses a constant current welding power source (with negative polarity DC or AC). However, gravity arc welding is not widespread since better and efficient automated welding methods are available.

SMAW Process Equipment

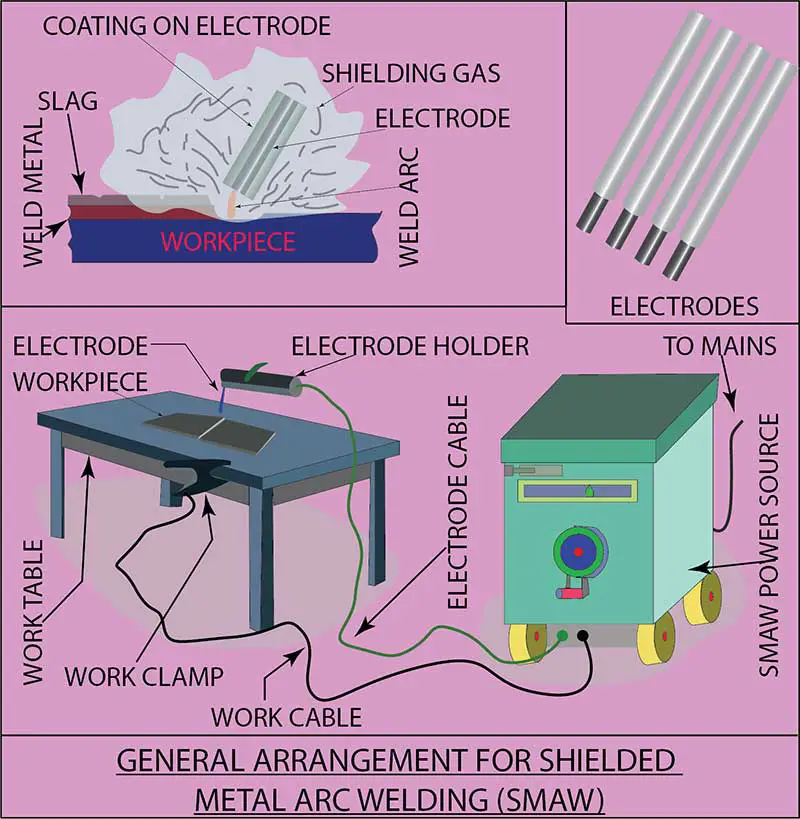

The equipment for the shielded metal arc welding (SMAW) process consists of:

- Constant current power source.

- An electrode holder.

- Welding cables.

- Ground clamp.

- Clamp for connecting the workpiece to the power source.

- Chipping hammer and wire brush.

1. Power source/supply

SMAW/MMA requires a constant high current (50 to 300 Amps) and a moderate low voltage (10 to 50 volts). The current requirement can be up to 600 Amps also. In order to match the required voltage, the incoming power supply (220 volts or above depending on the place) should be brought down using a transformer, and a rectifier is added when DC is required. Accessories used for managing the power supply are: step down AC transformer (using multiple coils), DC rectifier, inverter, and DC Generator. An inverter regulates the voltage through its electronic system, and an inverter welding unit converts 240 volts AC supply into the required 20 volts DC supply.

The electrodes used in SMAW are designed for use with alternating current (AC) and direct current (DC) sources. AC electrodes can be used with DC; however, all the DC electrodes may not be compatible with AC. The power source should be capable of functioning with a maximum no-load voltage (situations like- when the power source is connected to the electrode holder and the workpiece, and there is no arc “no welding is going on”). This character is required to minimize or eliminate electrical shocks/hazards.

The polarity used in the SMAW process primarily depends on the electrode used and the expected quality/properties of the weld. Direct current with a negatively charged electrode (DCEN) results in building up of heat on the electrode, higher electrode melting rate, and decrease in the depth of the weld. Direct current electrode positive (DCEP) and the workpiece negative increase the penetration of the weld. An AC power source leads to an even heat distribution and balance between the rate of electrode melting and penetration. Electrical generators and alternators run by an internal combustion engine can be used for using SMAW at outdoor locations where grid power is not available.

2. Electrode holder

The electrode holder holds the welding electrode and connects the welding electrode to the power source terminal (through a cable). The electrode holder usually is spring-loaded and can be pressed by the welder to open (insert the welding electrode) and close. The electrode holder is insulated, and the welder can hold it comfortably in his hand during welding. The electrode holder is available in various sizes, and the sizes are rated by their current handling capacity.

3. Electric cables

The cables connect the electrode holder and the workpiece to the respective terminals of the power source. A separate earth lead may be required to protect the welder and others from accidental shocks. The external protection (sheath) on the cable wire should be able to withstand the current, normal wear, dust, oil, and water, and the diameter of the cable depends on the current it carries (higher the current and duty cycle, the larger the diameter of the cable). The cables can be carrying copper or aluminum wire strands.

4. Welding shield

The welding shield is available in different forms, such as a hand-held welding shield, welding shield strapped to the welder’s head (can be flipped back when not in use), or a welding helmet with a flip-able welding glass.

Other accessories required are a clamp (C-type or any suitable type) to connect the workpiece to the power source, a chipping hammer and wire brush (to clear the slag), and welder safety gear.

Electrodes used in Stick Welding

Electrodes in the SMAW process can be operated with AC or DC sources, and all the AC electrodes may be used on AC or DC; however, all the electrodes meant for DC may not be adaptable to AC. The electrode selection for the SMAW process depends mainly on the material of the workpiece, required weld properties, and position of welding (flat, slant, vertical, overhead, etc.).

The metal electrode has a flux coating, which burns along with the electrode, and gives gases to protect the arc and the molten weld pool from oxidation and contamination. Further, the flux coating purifies the weld, improves the weld quality by providing alloying elements, and creates a protective slag on the weld bead, which can be chipped off later.

Related Article: What You Need To Know About Welding Electrodes.

Types of Shielded Metal Arc Welding Electrodes

1. Based on the rate of melting and solidification, there are three types of electrodes:

- Fast-fill electrodes are designed to melt and fill quickly (this increases the speed of welding).

- Fast-freeze electrodes are designed for quick solidification (useful when welding the vertically/overhead mounted workpiece).

- The electrodes having characteristics between fast-fill and fast-freeze type are called fill-freeze or fast-follow.

2. Based on the type of electrode and the flux coating used in the SMAW process has an influence on the stability of the welding arc, depth of penetration, rate of metal deposition, and suitability for welding of workpieces in different positions. The type of flux coating the welding electrode is of three types: cellulosic, rutile, and basic.

Cellulosic – Cellulosic electrodes have a good proportion of cellulose in their flux coating and are known for deep penetrating arc and fast burning rate resulting in high-speed welding. However, the weld bead quality can be coarse, and slag removal can be difficult due to its fluid state. This type of electrode can be used in any position, and the major characteristics of cellulosic electrodes are:

- Deep penetration.

- Can be used for vertical welding.

- Fairly good mechanical properties.

However, there can be a risk of cracking in the heat-affected zone due to the hydrogen generation.

Rutile – The second type, rutile electrode, has a high proportion of rutile (titanium oxide) in its flux coating. The presence of titanium oxide helps easy ignition of the arc, smooth arc during welding, and low spatter level. Rutile electrodes are general purpose electrodes, can be used in all positions with AC or DC power sources, and has good welding properties. This electrode is specifically recommended for fillet welding joints in horizontal or vertical positions.

The major characteristics of rutile electrodes are:

- Reasonable mechanical properties of the weld metal (properties like tensile strength).

- Profile of the weld bead is good.

- The slag can be chipped off easily.

The performance of the normal stainless steel (austenitic grade) electrodes used in the SMAW/MMA process is substantially improved by adding rutile (titanium oxide) in the flux coating. The presence of titanium oxide in the flux coating has improved the stability of the welding arc and surface finish of the weld bead. Special electrodes are developed for the welding of stainless steel containing high molybdenum.

Basic – The third type, the basic electrode, has a good proportion of limestone (calcium carbonate) and fluorspar (calcium fluoride) in its flux coating. This is a fast-freezing type of electrode and makes it adaptable for vertical and overhead position welding. Basic electrodes are used for the welding/fabrication of medium and heavy sections since they require good quality welding, resistance to cracks, and better mechanical properties.

Important features of the basic electrode are:

- Low hydrogen (less welding cracks problem).

- Current requirement is high.

- Welding speed is high.

- Difficulty in slag removing etc.

Metal powder electrodes – have an addition of metal (iron) powder in the flux coating, and the presence of iron powder in the flux enhances the maximum level of welding current. For the same electrode size, the electrode with iron powder in the flux gives a higher metal deposition rate and a higher percentage of metal deposited than an electrode with no iron powder in its flux coating. The slag removal usually is easy. These electrodes are used in the flat and vertical position welding, and the welding is fast due to high deposition rates.

Electrode storage and care – The quality of the welding depends on the quality of the electrode, and the quality of a good electrode may deteriorate due to bad storing. The coating on the electrode can absorb moisture (when exposed to the ambience), and damp electrodes are not suitable for welding. Because of this, the following care is necessary:

- Welding electrodes should be stored in a dry and well-ventilated place. The best thing will be to store a minimum quantity covering one or two days and replenish it on a daily basis. Strictly follow the storage instructions of the manufacturer.

- If the welder thinks that the electrodes have become damp, it is necessary to follow the manufacturer’s advice to remove the dampness (like warming it in a small oven) before using it for welding.

- Modern-day electrodes are available in hermetically sealed packs. However, if necessary, any unused electrodes must be re-dried according to the manufacturer’s instructions.

Classification of welding electrodes by AWS (American Welding Society)

For identifying different welding electrodes, the AWS (American Welding Society) has established a numbering system that tells the welder the type of current (AC or DC or AC/DC), welding position, etc.

Classification or identification of the SMAW electrode has five digits E XX XX, Example – E 70 18.

- ‘E’ indicates Electrode.

- The second and third digit indicates the minimum tensile strength of the weld produced by the electrode (sometimes this can be three digits). In our example, 70 indicates 70,000 PSI.

- The fourth digit indicates the suitability for welding in a specific position. Here 1 indicates all positions, 2 indicates flat and horizontal positions only, and 4 indicates flat, horizontal, vertical down, and overhead (numeral 3 is not used in this standard).

- The last two digits (you have to consider the last two digits and not “the last digit”) indicates the type of coating and current (AC or DC). In our example, 18 indicates an ‘iron powder low hydrogen’ coating, and the current can be AC or DC+.

You may find more code in some electrodes, such as E7018 H4R. Here H4 indicates low hydrogen (less than 4 ml per 100 grams), and R indicates ‘meets requirements of absorbed moisture test’. Also, there is the F group where F1 indicates ‘Fast-Fill’, F2 indicates ‘Fill-Freeze’, F3 indicates ‘Fast-Freeze’ and F4 indicates ‘Fill-Freeze (Low Hydrogen)’.

Related Article: A Guide To 6010, 6011, 6013, And 7018 Welding Rods.

Applications of Shielded Metal Arc Welding

SMAW or manual metal arc (MMA) welding process is a versatile and very popular process and finds many applications, they are:

- Maintenance and repair work.

- Construction of heavy steel structures, fabrication industry, pipelines, machine structures, boiler industry, shipbuilding, automobile chassis, etc.

- Welding of cast iron, carbon steel, alloy steels (low and high), different grades of stainless steel, etc.

- Welding of non-ferrous metals like copper and aluminum, and nickel and copper and nickel-copper alloys; however, SMAW welding is not popular for this category of metals.

- Welding of higher thickness metals using multiple passes.

- Providing a protective surface of the selected metal for corrosion resistance or wear resistance (hard-facing).

- Construction of offshore platforms and underwater welding.

- Stick welding process is highly suitable for welding of pressure pipeline which cannot be welded from inside.

- SMAW or Stick welding is extensively used in the shipbuilding industry, offshore welding, defense-related industries, and the fabrication of low alloy steels. The excellent quality of welding and resistance of the SMAW process against the cracks induced by the presence of hydrogen is the reason they are preferred.

- Fabricated structures used in the cryogenic application that has to operate at temperatures below 0ºC and various formulation of the SMAW welding electrodes (including the addition of nickel) makes the weld metal tough and sustain in extreme conditions.

Advantages and limitations of Shielded Metal Arc Welding

Advantages

- The equipment requires a low initial investment, and it is portable.

- Can be used in any position horizontal, inclination, vertical, and overhead.

- SMAW/Stick welding process is simple to learn and master compared to other welding processes.

- Can be used in an open atmosphere since this process does not use a protective gas (atmospheric air can disturb the protection gas shield).

Limitations

- SMAW welding process needs interruptions for changing the electrode (not a continuous process).

- Possibility of slag inclusion in the weld metal.

- Fumes are generated due to the burning of flux material (health hazard).

- The quality of the weld significantly depends on the welder’s skill.

SMAW VS GMAW

| No | Shielded metal arc welding (SMAW) – Stick Welding | Gas metal arc welding (GMAW) |

| 1 | Lower initial cost towards equipment. | Higher initial cost towards equipment (compared to SMAW). |

| 2 | Low operation cost since the process does not need a shielding gas. | Higher operation cost (compared to SMAW) due to the shielding gas and also the welding wire (electrode). |

| 3 | SMAW process uses a flux coated electrode. | GMAW process uses a bare continuous wire as the electrode, and some category of welding wires has an anti-corrosion coating on the wire. |

| 4 | The flux coated on the electrode burns along with the electrode and gives necessary shielding gas to protect the arc and the molten weld pool from atmospheric oxidation and contamination. The flux leaves a slag on the weld bead, which the welder should chip off immediately. | A shielding gas like argon, helium, or carbon-di-oxide (or a mixture of gasses) is delivered from the welding torch during welding to protect the arc and the molten weld pool from atmospheric oxidation and contamination. |

| 5 | The slag left by the flux coating protects the weld from atmospheric gasses, but there are chances that slag may get into the weld metal leading to welding defects. | There is no flux, and hence no slag, and no chances of slag inclusion in the weld metal.

|

| 6 | SMAW is highly versatile and can be used for welding in all positions. | Less versatile and welding in all positions is not preferred. |

| 7 | SMAW is a manual welding process, and automation is not possible due to the short length of the welding rod. Scope for human errors exists. | GMAW can be easily automated with less human involvement. Hence, minimum human errors.

|

| 8 | The welder has to hold the electrode in his hand and feed it during welding and has to interrupt in between to change the electrode. Hence, the productivity rate is low. | The welding wire is fed through a device into the welding torch, and the wire is fed continuously (without interruptions). Hence, the productivity rate is better than SMAW. |

| 9 | SMAW process leaves behind a slag that the welder has to chip off. The secondary operation may be required to improve the welding bead. | GMAW process does not leave a slag. Typically, secondary operations are not required to improve the welding bead. |

Stick welding safety consideration

- The welder has to deal with electric current, electric arc, hot components, welding fumes, thermal radiations, etc. He/she must take all the safety precautions and must wear safety gear for protection.

- The welder has to wear leather hand gloves, long sleeve jackets, shoes, good quality welding helmets (with flip-able welding glasses), and a mask (if there is no provision of built-in protection from fumes in the helmet).

- The welding enclosure should have good ventilation for the quick exit of the toxic gases formed during welding. Also, the welding enclosure must not contain inflammable/combustible items like fuel, oil, paper, etc.

- Many times, the welder works sitting inside a confined portion of the part being fabricated, such as a boiler, tank, ship tanks, etc. In such cases, proper ventilation is essential for the safety of the welder.

Conclusion

SMAW (Stick welding) process is here to stay, despite the availability of many advanced and automated welding systems. The main reasons for the popularity of SMAW are its simplicity to learn and use, portability, and low initial investment. The SMAW is versatile and very useful for maintenance works done in small workshops. This status may not change for a long time!

References: