Many offshore structures, such as oil rigs, subsea pipelines, and offshore platforms, take shape beneath the waves, and they all need specialized welding techniques during construction and post-construction maintenance. Such welding jobs executed under the water are called ‘underwater welding.’

Skilled professionals known as ‘underwater welders’ take on the challenging task of performing these critical welding jobs beneath the water’s surface.

In this article, we will guide you through the world of underwater welding. You will discover what underwater welding types are, how it functions, and the various welding processes employed in this unique line of work. As we dive deeper, you will also gain insights into the life of saturation divers and the inner workings of saturation chambers.

So, let’s dive in and immerse ourselves in the extraordinary world of underwater welding.

What is Underwater Welding?

When welding at elevated pressure underwater, such welding is called underwater welding. You can do the welding directly underwater (called wet welding) or inside a specially fabricated enclosure placed under the water (called dry welding). So, you can define underwater welding as welding done underwater and at elevated pressures.

The welding done on the land and that done underwater follows similar technology; however, an underwater welder has to work submerged deep under the water, at elevated pressures, adverse conditions, and inbuilt dangers associated with this profession. Hence, strict safety precautions are very important.

The difficulties faced by welders who are welding deep underwater are elevated pressure, low temperatures (depending on the depth), poor visibility, strong water currents, and also reduced quality/strength of the welds.

Related article: Underwater Welding Death Rate

Types of Underwater Welding

Underwater welding techniques can be divided into two basic categories: dry and wet. Both dry and wet underwater welding is done underwater; however, dry underwater welding is done in an enclosure to create a dry environment around the weld area.

Dry Underwater Welding

When underwater welding is carried out in a specially fabricated enclosure called ‘habitats’ (hyperbaric chamber/enclosure) placed under the water, it is called dry underwater welding. Dry underwater welding is also called hyperbaric welding since the welding process is performed at elevated pressure in a sealed chamber filled with a mixture of gas (normally helium and oxygen).

Most welding processes such as shielded metal arc welding (SMAW), flux-cored arc welding (FCAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), plasma arc welding (PAW) could be performed at hyperbaric chamber; however, GTAW is typically used for dry underwater welding.

A hyperbaric chamber specifically made for the welding work on hand is lowered into the water (location of the work). The water is pumped out, and the space in the chamber is filled with a gaseous mixture of helium and oxygen. The hyperbaric chamber is pressurized to the correct level to prevent decompression sickness.

Presently dry hyperbaric welding is limited up to 400 meters (1312 feet) of water depth, and experiments are in progress for increasing the depth. The limitations are the physiological capability of underwater welders to operate the welding equipment at that pressure and the construction of a hyperbaric chamber for such water depths.

Advantages of Dry Underwater Welding

- The dry habitat is warm and comfortable, and the underwater welder is safe from dangerous water animals and ocean currents.

- In the absence of water to quench the weld joint, the cooling of the weld joint takes place properly, and the weld joint is free of cracks. The welder has good visibility of the work.

- Non-destructive testing (NDT) can be undertaken, and welding defects can be corrected.

- The work done by the underwater welder can be monitored visually by the onshore staff.

- Dry underwater welding is preferred where there is a need for good quality welding, and the work location is at a higher depth.

Drawbacks of Dry Underwater Welding

- Hyperbaric chambers take time to plan and arrange.

- The process is extremely costly since the chambers are unique for each job and cannot be reused.

- The support staff and equipment on the surface are costly.

- With the increase in depth, the arc requires a higher voltage.

- Dry underwater welding cannot be adopted in case of emergency or breakdown.

Wet Underwater Welding

When you carry out the welding in a wet environment, deep under the water, it is called wet underwater welding. The underwater welder dives into the water wearing the diving gear and does the welding.

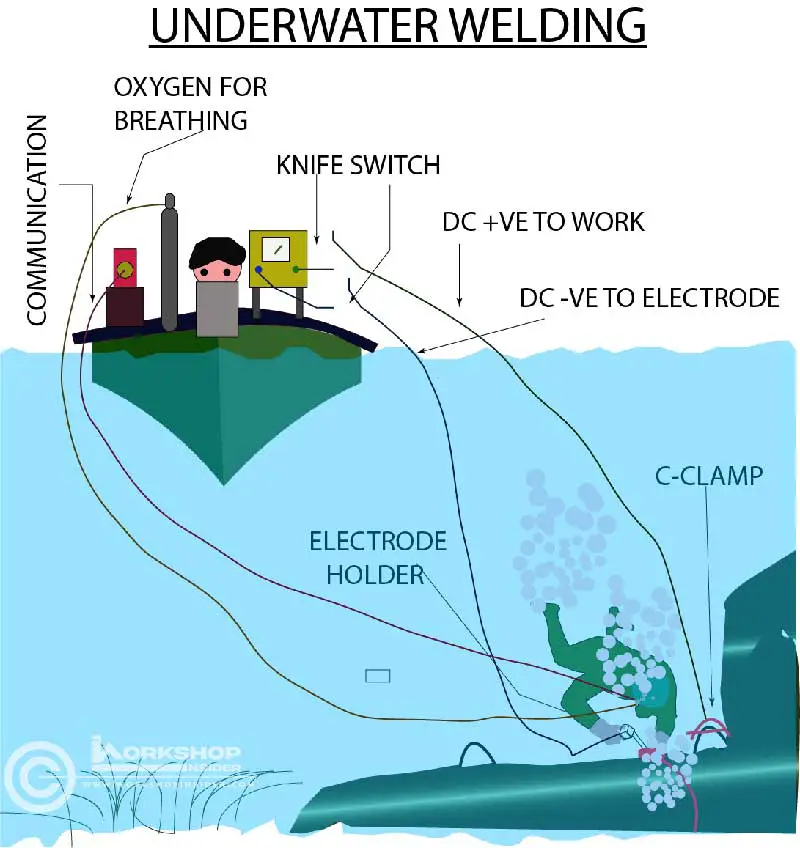

Wet underwater welding brings the welder, the welding rod, the electrode holder, electric cables, and other equipment to direct contact with water. All these accessories, including the underwater welding rod, are insulated and waterproof. The underwater welder wears thick rubber gloves. The DC source at the surface supplies 300 to 400 amps of current.

Wet underwater welding is the only option to deal with an emergency. The main issues connected with wet underwater welding are the risk of doing welding underwater, the welding done in an environment of water makes the weld joint cool fast, which may lead to quality issues such as welding cracks, and finally, the quality of weld joint also depends on the approachability of the part to be welded.

Advantages of Wet Underwater Welding

- Wet underwater welding is more versatile than dry underwater welding, and the cost incurred is less.

- It can be done fast and is the only method during an emergency.

- Wet underwater welders can access parts of the underwater structures, and pipelines that dry underwater welding cannot access.

- No enclosures are needed, and the welding equipment can be mobilized faster.

Drawbacks of Wet Underwater Welding

- Rapid cooling of the weld joint due to the heat dissipating through the surrounding water affects its strength and ductility.

- Poor visibility in the water.

- The underwater welder is exposed to ocean currents and other threats.

- The integrity of the welding done by wet underwater welding cannot be guaranteed since there are no means to inspect and ensure it. Much depends on the skill of the underwater welder and the technic adopted.

- There is a risk of non-detection of welding defects in wet underwater welding.

How Does Underwater Welding Work?

Wet Underwater Welding Techniques

Let us consider the process of wet underwater welding first; a kick-off meeting is held between the project team and the underwater welder to discuss the work on hand, conclude the method and underwater welding process, and ensure that everyone is aware of the project details.

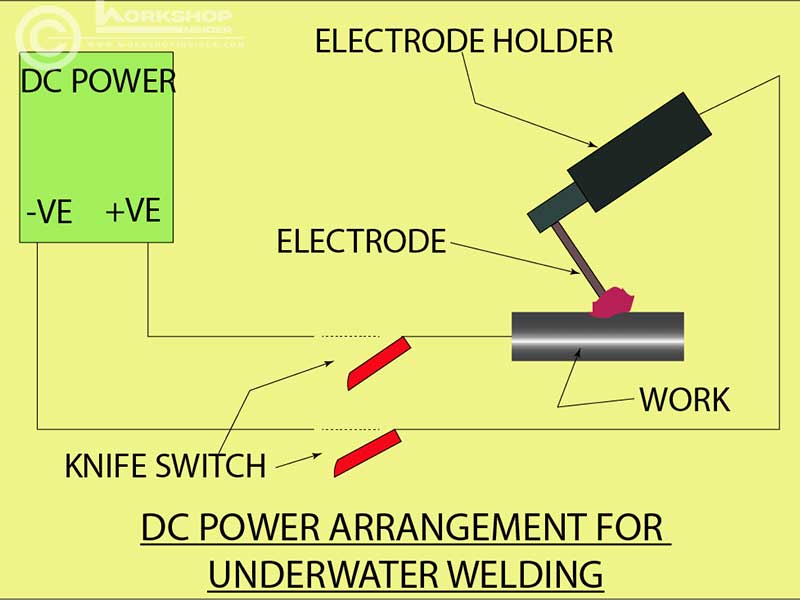

The current requirement for underwater welding is typically 300 to 400 amperes. Underwater welding uses direct current settings rather than alternating current, as it is safer for underwater welders to work with.

All the accessories, such as connecting cables, electrode holders, and underwater welding rods, are waterproof and properly insulated to ensure there will not be electric leakage when used underwater. It is always preferred and safe to do trial welding in water to ensure the safety of these accessories.

SMAW (shielded metal arc welding) process with a waterproof underwater welding rod is typically used in wet underwater welding. The underwater welder wears his diving and safety gear and dives into the water to the work location.

The work is connected to the positive (+) terminal of the DC source and the electrode holder to the DC source’s negative (-) terminal. The connection to the work is typically made with a C-clamp.

The underwater welder selects a location nearer to the weld joint, cleans and shines it with a wire brush, and clamps the C-clamp firmly to the workpiece. The underwater welder may lightly tack-weld the C-clamp to the workpiece if necessary.

Underwater welding brings the welder, the welding electrode, and the welding accessories into direct contact with water. The electrode holder is heavily insulated and specially designed for water cooling, and the underwater welder wears electrically insulated hand gloves.

The connection from the DC source to the workpiece and the electrode has a heavy-duty knife/isolation switch in the circuit monitored by the staff on the surface (ship). The underwater welder can communicate with the team on the surface (ship).

The isolation switch always remains disconnected except during welding and connecting the work. The electrode holder with the DC source is switched on by the staff on the surface only on the instruction of the underwater welder. As an underwater welder, you will communicate with the ship deck’s surface staff from the moment you dive into the water to the moment you complete the work successfully.

When ready for welding, the underwater welder instructs the staff on the surface to close the knife switches and does the welding. They advise the surface team to disconnect the switches for changing the electrode or during breaks.

Usually, there will be established commands to connect or disconnect the electric power. One such command can be ‘make it hot’ (for connecting the work & electrode holder to the DC source) and ‘make it cold’ (for disconnecting).

The electric arc between the work and the welding electrode heats the workpiece and the welding rod. The workpiece is connected to the positive terminal and the electrode holder to the negative terminal; this ensures 60% of the heat generated goes to the wok and 40% to the electrode.

The arc generated in water creates gas bubbles (hydrogen, carbon dioxide, and carbon monoxide), which protects the weld joint. The flux coating on the electrode melts and gets deposited as a slag on the welded joint. The slag protects the weld joint and reduces the rate of cooling.

The production of bubbles obstructs the visibility of the welding to the welder; however, a good welder knows how to manage this. Slag deposition on the weld joint helps slow the cooling rate; however, rapid cooling of the weld joint is a major obstacle in ensuring a crack-free weld joint.

An underwater welder is expected to accomplish their work in challenging situations. The technique of underwater welding is equally beneficial for both inland water and offshore sites. The welding process on land differs from welding underwater, and all the welding techniques used on land may not be adaptable for underwater welding.

Few underwater welding jobs, like the repair of ships, are carried out in shallow depths, and other welding jobs, such as pipelines and structures, are carried out deep under the water.

Dry Underwater Welding Techniques

Few underwater welding jobs, like the repair of ships, are carried out in shallow depths, and other welding jobs, such as pipelines and structures, are carried out deep under the water.

Dry underwater welding process, in the dry underwater welding, the habitat or the hyperbaric chamber is lowered into the work location and made ready for the underwater welder to do his work. Since the dry underwater welding is done in a dry ambience, DC or AC can be used, and GTAW (gas tungsten arc welding) is generally used for dry underwater welding.

The underwater welder wears his diving and safety gear, dives into the water, reaches the work location, and enters the hyperbaric chamber. They will take out the diving suite and starts the welding work. The welder breathes the mixed gas helium and oxygen.

In some cases, when the depth of the location is more, the underwater welder may travel in a small chamber (diving bell) from the surface to the hyperbaric chamber.

Overall degradation of welding in terms of capability and efficiency is found to happen at elevated pressures.

Welding Processes Used for Underwater Welding

Wet Underwater Welding Processes

Commonly Shielded Metal Arc Welding (SMAW) is used for wet welding. SMAW process is versatile, cost-effective, and is easy for the underwater welder to strike an arc between the welding rod and the work.

Flux Cored Arc Welding FCAW-S (self-shielding) process contains a flux that protects the weld pool. FCAW-S process may be used for cast iron, nickel alloy, and other metal alloys. The consumable electrode has a tube filled with flux at the center. The electrode in the form of a wire is fed automatically.

Welding processes like Gas Tungsten Arc Welding (GTAW), also known as TIG (tungsten inert arc welding), Gas Metal Arc Welding, also known as MIG (Metal Inert Gas welding), etc. uses inert gas to shield the weld joint and hence cannot work under the water.

Dry Underwater Welding Processes

Gas Tungsten Arc Welding (GTAW), also known as TIG (tungsten inert arc welding) is typically used for dry underwater welding because of its good quality welding and its ability to perform at elevated pressures (underwater). The underwater welder uses the tungsten electrode to melt the filler wire, and the molten metal is deposited on the weld joint. TIG welding produces a quality weld joint.

Flux Cored Arc Welding ((FCAW-G (gas-shielded)), Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding, and Plasma Arc Welding (PAW) can also be used for dry underwater welding; however, they do not perform well at elevated pressures. Shielded Metal Arc Welding (SMAW) is not preferred due to the fumes/smoke it generates.

Saturation Divers and Saturation Chamber

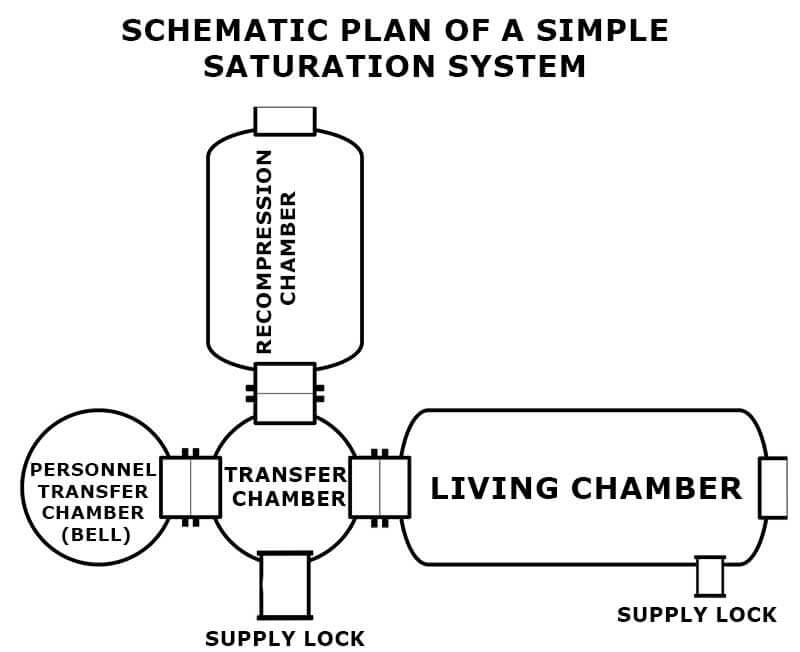

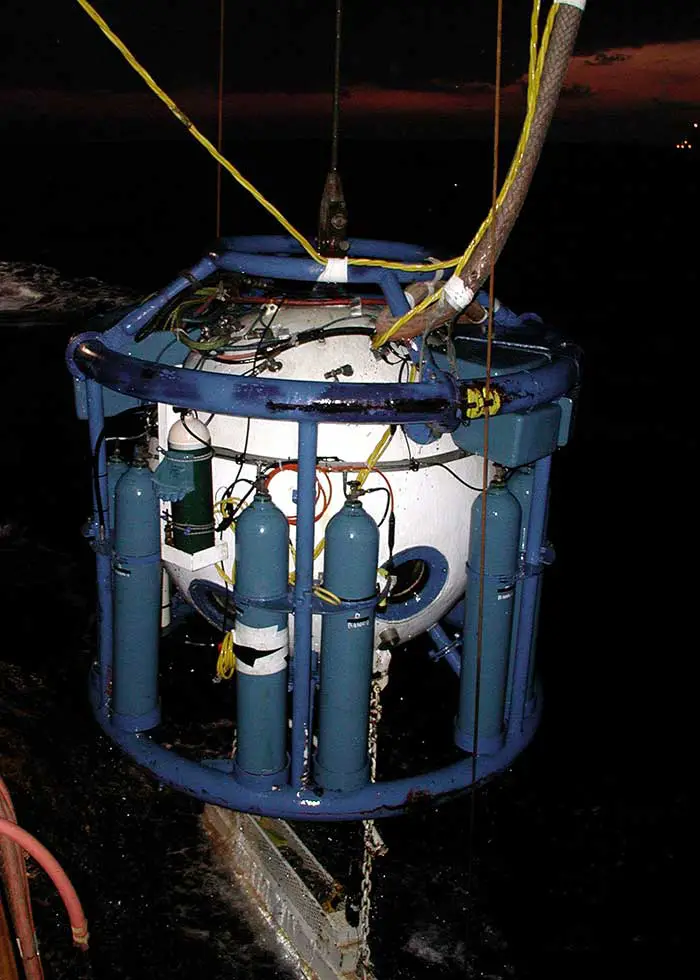

A capsule of approximately 15-16 feet ×7-8 feet is built in a ship and is maintained at 18-19 times more pressure than the atmospheric pressure, which is called the saturation chamber.

This saturation chamber is home for typically six men who eat, work, play, rest, and sleep here for 28 days at a stretch. The men are saturation divers who work for the company engaged in underwater welding at a depth of 500+ feet.

When an underwater welder dives into the deep water, the pressure compresses the gases like carbon dioxide and nitrogen in his blood/tissues. He is fine as long as he stays in that depth; however, at the end of the working day, if he comes up to the surface fast, the compressed gases in his blood/tissue try to expand, resulting in ‘bends’, which is very painful.

After returning to the surface, the diver may take 5-6 days of rest/decompression before resuming his work. This means that the company has to pay for six days for one day’s work. This is not an economic proposition. Hence, the idea of a saturation chamber has come up.

This system keeps the underwater welders (called saturation divers) at the same pressure throughout the day for 28 days. The saturation chamber on the ship is maintained at the same pressure as at the work location (at a depth of 500+feet).

A pressurized diving bell takes the saturation diver from the saturation chamber to the work location. After completing the shift of the saturation diver, the diving bell takes the saturation diver back to the saturation chamber in the ship. This will continue for 28 days; after 28 days, a new batch of 6 men will replace the old batch. The six men in the saturation chamber can work in shifts.

Welding Equipment and Tools for Underwater Welding

The underwater welder needs two types of equipment: diving and welding. Welder safety is the major criterion for choosing this equipment, and the equipment must meet all the set safety standards. The complete equipment should undergo regular maintenance as per the laid-out standards.

Underwater Diving Equipment

1. Diving Helmet: A diving helmet is used by the underwater welder when they go under deep water. This helmet allows breathing for the underwater welder and has a welding screen in the front, which protects the eyes during underwater welding. The welding screen can be flipped to open or close.

2. Diving Knife: A diving knife is a multipurpose tool, and the underwater welder can use this to free himself/herself from a critical situation, wedge open a door, etc.

3. Umbilical Cord: This supplies the breathing gas from the surface to the underwater welder.

4. Harness: A harness keeps the underwater welder floating in one place during welding.

5. Gas Panel and Compressor: This is located at the surface and is continuously monitored by the surface staff to ensure a continuous supply of breathing gas to the underwater welder.

6. Bailout Gas: This is like a small scuba tank with an underwater welder for emergency use.

7. Diving Suit: Underwater welders must wear a dry suit to protect themselves from climatic conditions under deep water. Depending on the depth of work location and the environment, the dry suit can be of neoprene, rubber, or shell. Many underwater welders wear a cover-all over the dry suit to protect against molten weld metal falling on their bodies.

8. Rubber Hand Gloves: An underwater welder wears a pair of latex hand gloves and thick rubber hand gloves (over the latex) to protect themselves from electric shocks. The design of the hand gloves should be such that it does not allow the water to enter into the underwater welder’s body.

Underwater Welding Equipment

1. DC Power Source: The power source should be a Direct Current welding generator capable of 300 to 400 amps on 65 Volts open circuit. The equipment DC circuit must include a circuit breaker.

2. Underwater Electrodes: The electrodes used for underwater welding are extremely resistant to water, highly insulated, flux coated, and have a high yield strength. All these properties are necessary for safe and good-quality underwater welding.

3. Waterproof / Heavily Insulated Electrode Holder (Stinger): The electrode holder for underwater welding should be highly insulated, water-cooled, ergonomic and, lightweight, properly angled so that the underwater welder can use it safely and without much strain.

4. C-clamp: To connect the positive terminal to the workpiece.

5. Waterproof and heavily insulated cables: Connecting the DC positive terminal to the workpiece and the DC negative terminal to the electrode holder, the cables should be excellent. Each of these cables has a knife switch at the surface (ship) and is controlled by the surface staff.

6. Knife switch: A knife switch is a simple switch the surface staff uses to connect or disconnect the DC power to the electrode holder and the work. The knife switch is always in the disengaged (disconnected) position except during welding. The surface staff connects the knife switch only after receiving a clear communication of ‘make it hot’ from the underwater welder.

7. A communication System: The communication system between the underwater welder and the ground staff should be of good quality and should be able to work in an underwater environment.

8. Miscellaneous tools: Such as a chisel and chipping hammer.

Friction Welding and Resistance Welding Underwater

Friction Welding

Friction Welding is a solid-state welding technique, offers several unique advantages in underwater application such as: the absence of a need for shielding gases, controlled heat generation which limits the heat affected zone (HAZ) enhancing the properties of the materials welded, and increased corrosion resistance due to high-quality, stress-reduced joints formed.

Notwithstanding, using friction welding underwater presents challenges like needing special equipment to counter water currents and machine adjustments to compensate for water resistance.

Resistance Welding

Resistance Welding is another remarkable method for underwater welding, which involves passing an electric current through pieces of metal to create heat sufficient for melting the metals together.

Boasting safety from electric shock and harmful UV radiation, versatility in material use (steel, aluminum, titanium), and minimal distortion of welds, resistance welding underwater is a highly preferred technique for many projects.

However, just like friction welding, resistance welding underwater has its own set of challenges, including coping with water’s buoyancy, maintaining a stable power supply in the face of water resistance, and ensuring weld quality is not compromised by equipment issues.

Certification for Underwater Welders

Underwater welders must have a commercial diver certification from a commercial diving school and be certified welders. Certifications can include welding, diving, ASNT Level II and CSWIP.

A “welder diver” is a certified welder who is also a commercial diver, capable of performing tasks associated with commercial subsea work, weld setup and preparation, and who can weld following the AWS D3.6, Specification for Underwater Welding (i.e., wet or dry), and other weld-related activities.

Related Article: How To Become Underwater Welder? | Underwater Welders Salary

Associated Risks and Safety Considerations

Underwater welding involves numerous risks, but proper safety precautions and procedures can effectively manage these risks.

Underwater Welding Risks

1. Challenging work conditions: Welders work in deep water with elevated pressures and often poor visibility.

2. Electric shock or electrocution: Water’s conductivity increases the risk of electric shock or electrocution.

3. Decompression sickness: Rapid ascent from deep water may cause decompression sickness, also known as “the bends.”

4. Hypothermia: Extended exposure to cold water can lead to a dangerous drop in body temperature.

5. Pressure-related health issues: High-pressure underwater environments can negatively affect the lungs, ears, and nose.

6. Marine animal hazards: Underwater welders should be aware of potential encounters with potentially dangerous marine animals, like sharks.

Underwater Welding Safety Considerations

1. Regular inspection and maintenance: Check diving gear, suits, and accessories regularly and maintain them in good condition.

2. Essential diving accessories: Remember vital diving gear like a diving knife and rubber gloves.

3. Welding equipment checks: Conduct trial welds to ensure equipment is functioning properly before starting work.

4. Clear communication: Establish an effective communication system between underwater welders and surface staff.

5. Physical limitations awareness: Recognize and respect personal physical limitations to avoid health issues underwater.

6. Safety during welding: Disconnect power during breaks and communicate with surface staff to ensure safe welding practices.

7. Use DC generators: Use DC generators with straight polarity and avoid using AC current due to the increased risk of electric shock.

8. Maintain appropriate welding speed: Work at a safe, controlled speed to prevent accidents.

By understanding the risks and following recommended safety considerations, underwater welders can effectively manage hazards and perform their duties safely and efficiently.

Application of underwater welding

Underwater welding has a wide range of applications in various industries. Some of the key areas where it is frequently utilized include:

Underwater pipelines: Laying, repairing, and maintaining underwater pipelines between states or countries for oil and gas transportation often requires underwater welding.

Ship repair and maintenance: Dockyards extensively use underwater welding for repairing and maintaining ships, submarines, and marine vessels.

Offshore drilling rigs and platforms: Construction and maintenance of offshore drilling rigs and platforms rely on underwater welding to ensure their structural integrity.

Underwater nuclear power centers: The emerging field of underwater nuclear power centers presents new opportunities to apply underwater welding techniques.

Underwater mining: Underwater welding is also employed during underwater mining operations to support the infrastructure and equipment required.

By employing underwater welding, industries can efficiently carry out essential tasks in challenging underwater environments, contributing to the growth and maintenance of critical infrastructures.

References:

- Leisure pro – AquaViews – SCUBA Magazine.

- Wikipedia encyclopedia.

- Commercial Diving Academy.

- American Welding Society.