Recent technological advances have changed manufacturing processes in quite an exceptional manner. The CNC industry has developed better equipment that allows us to build even the most complex geometries: The Five-Axis machining tools.

This equipment, principally found in the aerospace, naval, and automotive industries, aids the manufacturing process of topologically optimized parts. The manufacturing process of these parts, designed to reduce weight, would not be possible using ordinary methods. However, this process will not take long. Machining time is one of the main reasons to upgrade your workshop with one of these tools. Five-axis machining tools reduce time by removing secondary processes from your workflow.

In the following article, we will introduce you to what Five-Axis Machining Tool are, their applications, benefits, and why you should upgrade your workshop with one of these.

What is Five-Axis Machining?

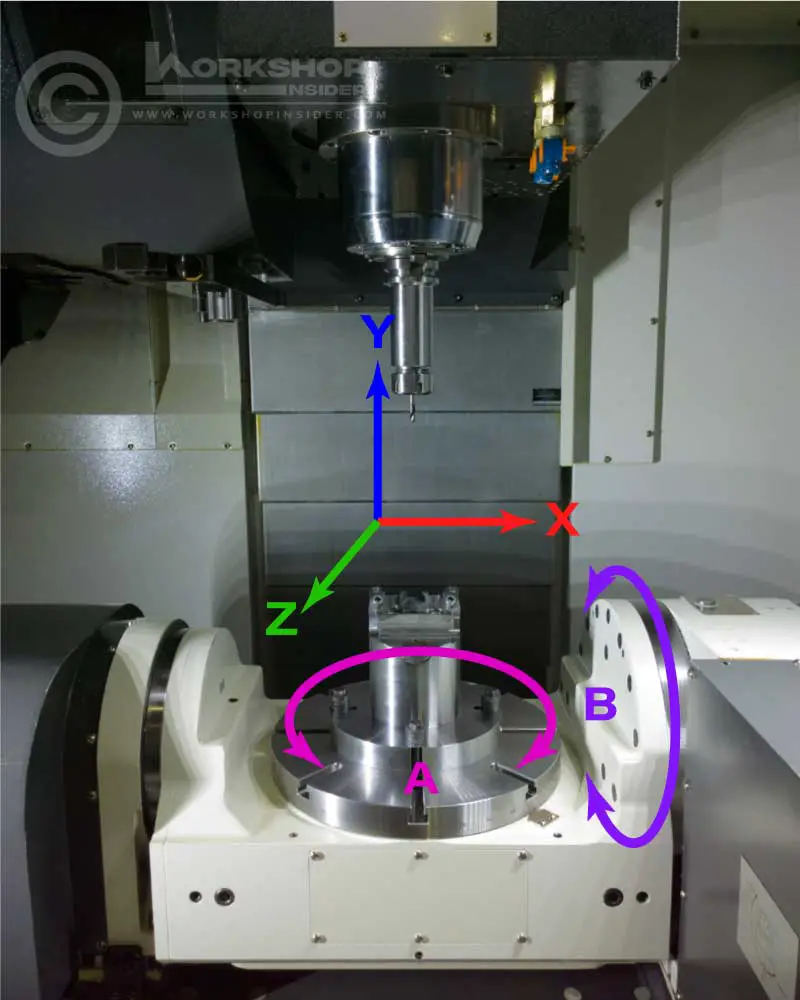

CNC machine-tools are classified by the degrees of freedom of the cutting tool. As the name suggests, in five-axis machining centers, the cutting tool has five degrees of freedom. In this case, the cutting tool can move along the three principal axes, let us say, X, Y, Z, and it also has two rotational movements commonly referred to as A and B, known as tilt and rotation axes.

All these movements options allow for a better and multidirectional approach to the raw material. Also, five-axis machining equipment can perform all the processes carried out by lathes and mills, making them a compact solution for your workshop.

In contrast with the regular lathe or mill, five-axis machining equipment has no manual operation mode. The movements performed by these machines are too complex and would need a hard-to-handle system so that a human can operate them. This not only makes it precise enough to achieve closer tolerances, but it also reduces the total amount of time required to machine a product and makes it safer for humans. The need for a computer-driven interface increases the cost of five-axis equipment.

This equipment is safer because the machining process is carried out in a protected chamber isolated from the workshop environment. In case a cutting-tool fail due to high load or excessive wear, a thick chamber surrounding the machining table will receive all the impact of the tool’s debris.

Why upgrading to a five-axis machining system?

There are quite a considerable amount of reasons to upgrade your workshop equipment to five-axis machining. This advanced equipment not only reduces the overall machining time but also improves the workshop environment. Improvements come from the fact that it occupies less space, and in most cases, it could even replace your older machinery.

We are going to describe some of the benefits of these machining tools in the following sections.

1. Five-Axis Technology Ensures the Production of Even the Most Complex Geometries

First of all, as technology continues to get better, older machines are rendered obsolete, meaning that your equipment will not be able to catch up with the customer’s requirements.

Most design software used nowadays includes the possibility to generate topologically optimized products. Always looking to reduce weight, this software generates pieces with odd shapes and complex geometries. These shapes would not be able to be produced using ordinary lathe and mill techniques. These hard-to-reproduce shapes may also be impossible to obtain using popular metal-casting methods.

The mobility achieved when using these automated machining centers allows reaching the raw-material from every possible angle, providing more efficient ways to use the cutting tools.

Besides, customers notice when your equipment is up-to-date. Five-axis machining centers are appealing not only because of their advanced technology but because these tools also have their isolated environment, keeping chips and debris away from your work-shops floor.

Most metalworking businesses recycle chips removed from their raw-material. When utilizing a five-axis machining center, these chips fall into a collection box located at the bottom, keeping the workshop clean and reducing accidents.

2. Higher Precision and Increased Tool Efficiency

The production of machine components involves the use of high-speed cutting tools made from special steel alloys. Most of these tools require a specified cutting angle relative to the raw material to ensure the highest efficiency. However, this angle is difficult to reach using conventional machining equipment.

When working with five-axis machining centers, the cutting tool will reach every single zone, improving the overall process efficiency and increasing the cutting tool’s duration. The increase in durability will reduce costs, achieve better finishes, and reduce the time invested in changing the cutting tool.

Tolerances are improved as well. The motion control system of these CNC machines is outstanding. The use of servo motors for the rotary axes improves their response. Reaching up to 20,000 RPM for the turning axis and up to 180 for the tilt axis, smoother surfaces are obtained.

Conventional 3-axis machinery has a hard time when trying to reproduce complex contours, especially in close zones of the raw-material that cause interference.

The ability to tilt and rotate the raw material around the A and B axes makes it easier for the cutting-tool to reach interference zones. This capability entirely exploits the cutting tool’s potential, principally in a surface finishing process. Apart from allowing to achieve closer tolerances, five-axis technology will eliminate the need for secondary machining processes.

3. Increase the Production Rate of Your Workshop

One of the most relevant features of five-axis machining is that it molds perfectly to your workshop environment. In either a large manufacturing company or a medium-size workshop, these machines improve the workflow. By removing processes and equipment from the production line, you will save both time and money.

More than 80% of the parts fabricated in CNC workshops require the use of at least a mill, a lathe, and a drilling bench. Five-axis machinery can replace these machines with ease, reducing the time needed to move the parts from one tool to another and performing supplementary processes such as finishing, threading, and knurling.

The use of large tool turrets allows preparing up to 18 cutting tools before starting the manufacturing process. These tools alternate between procedures to achieve better surface finishes, contours or removing larger quantities of material, depending on what is required.

Large industries make their decisions around cost and time. Five-axis machining equipment offers more than this. By upgrading your workshop, your company will make its way to an optimized process using the latest technology, drawing attention from more customers, and increasing your company’s popularity and earnings.

4. A Complete Automated Process That Is Easy To Program

CNC equipment is all about automation, and five-axis machinery complies with this. One of the major drawbacks for companies to upgrade their machinery is the need for highly-experienced employees. However, when it comes to five-axis CNC, this is not the case.

Technology not only upgrades the body of the machine but its software too. By providing easy-to-understand user interfaces linked to most CAD-CAE programs used nowadays, programmers can create new five-axis tool-paths similar to those used in three-axis equipment.

Besides, most suppliers include, in their sales packages, resources directed to capacitate your employees. It is a way for suppliers to let you know that you can trust in their product and that there’s no need to replace your employees or hire new ones to assist them.

Some software even creates preliminary tool-paths to improve operational efficiency. Based on the shape and type of the raw material, tools selected, and procedures to perform, these tool-paths work as a guide for your employees. Programmers may review the code and carry out minor changes to improve efficiency even further.

Five-axis equipment is not to be feared. Suppliers not only invest time and resources on the machine’s body. Its core, the software, is highly improved with every new version to maintain customers interested in their product.

Industrial applications for Five-Axis machining tools

Any industry with high production rates can take advantage of a five-axis machining center. One of the most popular applications found is prototyping. Either for aerospace or automotive prototyping, five-axis machining tools are chosen as the favorite machinery thanks to their capabilities.

Easy to fabricate geometries are seldom in both of those industries. Since they are focused on topological optimization to increase resistance by reducing all the possible weight, five-axis equipment accommodates perfectly in such a prototyping inclined workshop.

High-performance vehicles also require carefully designed parts to improve their lap times and street-performance. Both stock car manufacturers and car enthusiasts need to make their cars unique. To do so, some components are far from ordinary and require manufacturing processes carried out by five-axis tools with ease. Engine blocks, wheels, pistons, and even futuristic rear-view mirrors are just some examples of parts manufactured using five-axis tools.

Another industry that takes advantage of the five-axis machine’s capabilities is mold making. Mold fabrication requires precision and excellent surface finishes. However, it may also involve shapes that would be difficult to reproduce using conventional machining centers.

In mold-making, interferences are common, and five-axis equipment knows how to deal with them. The rotational axes ensure reaching every zone with just a tilt or rotation. Five-axis equipment is a must in the mold-making industry, working as a primary procedure to improve efficiency and results.

Other industries that use this equipment are the naval, military, scientific research, orthopedics, and the list goes on. Nowadays, these tools are part of the most advanced workshops.

How to Select Five-Axis Machinery That Matches Your Needs?

If you are thinking of purchasing a five-axis machining center for your workshop, there are many factors to consider at first. What material will you machine the most? Is your intention to mass-produce parts for another industry? You need it to be rigid? Would you prefer to save space?

These are just some of the questions you and your engineers must be asking if intending to purchase a five-axis machining center. In the following sections, we will give you an idea of what type of five-axis equipment you should order depending on your needs.

Simultaneous Five-Axis vs. 3+2 Machinery

There are two main types of five-axis machining tools. Ones are known as simultaneous or full five-axis tools and the other as 3+2 machining equipment.

When classifying this equipment, math fails because 3+2 is far from being equal to 5. As the name suggests, simultaneous five-axis machining centers can perform movements in the five axes simultaneously. Meanwhile, 3+2 machinery is simpler. Think of them as a mill with a rotary axis at the material support table. The table will not turn as long as there is movement in the X, Y, Z axes.

At this point, it must be clear that simultaneous five-axis involves a more complex software and that it can remove material in a better way. However, this doesn’t mean that 3+2 is obsolete technology because they both have their advantages and are equally preferred in different working environments.

Simultaneous five-axis machinery fits very well in large industries with high production rates. The contouring process for these tools is both faster and smoother. The ability to move the cutting tool and the raw material at the same time reduces the steps taken by the machine because the only time the process is interrupted is to change the cutting tool.

Medium-size and smaller workshops could use 3+2 equipment without experiencing delays in their expected delivery time. 3+2 equipment is cheaper, but it also performs very well. The only drawback that keeps it away from larger production rates is the constant stops required to rotate and position the raw material to continue with the machining process.

These stops considerably increase production time, and both contouring and finishing processes are affected. This does not mean that the quality of your parts will be affected; you just may need some additional actions to ensure that tolerances meet your client’s requirements.

So, what type of five-axis machining center suits better for my workshop? They both could, but if your needs are more inclined to increase production rates, you will probably go for a simultaneous five-axis machining center. On the other hand, if you want to create unique parts without the need for large quantities, 3+2 equipment is cheaper and will get the job done.

Horizontal vs. Vertical

Horizontal machines tend to work better when machining large, heavy parts that require more horsepower and fewer RPMs. Parts requiring extensive removal of material are machined better in these tools because of the additional space for the chips, which usually go into a conveyor located at the bottom. You should go for one of these if you intend to machine materials such as titanium and steel.

Vertical five-axis occupy less space, are lighter, and their motors achieve higher RPMs. They work faster and are excellent at producing small parts from a lighter material such as aluminum. One inconvenience of this type of five-axis machinery is that they have almost no space for chips, requiring constant stops to remove the carrier before it gets full. On the other hand, the operator has better access to the machine.

Swiveling-Head vs. Trunnion Style

Swivel-head machines come with a non-tilting table excellent for loading heavier parts. In this type of machinery, tool rotations occur above the table. Interferences tend to be seldom, making the swiveling-head type a perfect choice to use shorter cutting tools. Also, this equipment is more versatile, making it popular to machine stronger materials and larger parts.

Trunnion style contains both rotary axes in the table while the spindle head remains stationary. They have better undercut capabilities with a better reach to the bottom of the part. Trunnion style five-axis equipment is preferred when there are larger work volumes and higher material removal. Due to their undercut capabilities, these are often used in the mold-making industry.

Conclusion

Five-axis machining centers are the latest piece of manufacturing technology. Being used nowadays in a large number of industries, particularly those dedicated to prototyping and science.

These tools are both excellent pieces of equipment and software, created to fulfill the need for a tool that can replace the conventional machining methods. As time goes by, we will see these tools take over the market.

You may want to expand your brand by being one of the first ones using them. Besides, if you are a hobbyist with a small workshop, you should give them a try to expand your toolset and explore better ways to manufacture your projects.

Read Also: An Overview Of CNC Machining.

References