Understanding the principle of magnetism and demagnetization process is essential for magnetic particle testing experts and technicians. Magnetic particle testing (MT) is based on the laws of magnetism; hence, this NDT method is restricted to the inspection of materials that can support magnetic flux lines for detecting discontinuities that are located at or near the surface of ferromagnetic components and structures.

Ferromagnetic, paramagnetic, or diamagnetic are the three classifications of metals based on their magnetic behaviour.

Ferromagnetic metals are the metals that can become easily magnetized and strongly attracted to a magnet. Examples include iron, nickel, and cobalt.

Paramagnetic metals are the metals that cannot be magnetized and very weakly attracted by a magnet. Examples include aluminium, titanium, and iron oxide.

Diamagnetic metals are the metals that cannot be magnetized and very slightly repelled by a magnet. Examples include bismuth, gold, and antimony.

Principles of Magnetism

Polarity

Polarity is the tendency of a magnetic rod when suspended at its centre to align itself with the Earth’s magnetic field and eventually resulting in one end of the bar will point towards north while the other end towards the south.

Magnetic Forces

Magnetic force is the tendency of two different poles of two magnetic to attract each other or two similar poles to repel each other, e.g. the attraction force observed when placing north pole of a magnetic nearby south pole of another magnetic, the closer they come together, the stronger is the magnetic force. This attraction/repel force is the magnetic force.

Magnetic Field

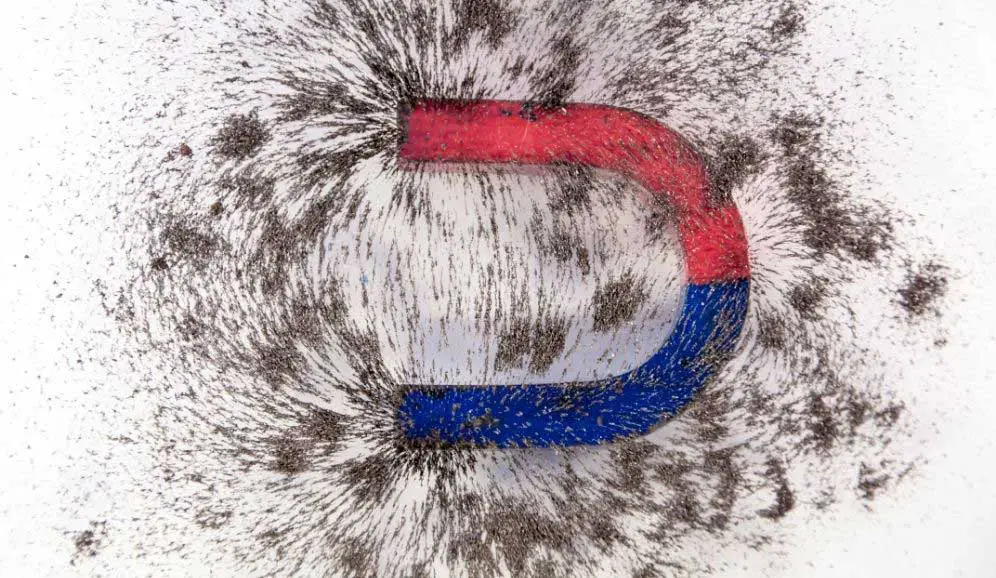

The magnetic field is the force field that surrounds any magnetic material where attracting and repelling force can be observed. The magnetic force appears in invisible lines that flow from the north pole to the south pole through the air and from south pole to north pole within the magnet to complete the magnetic circuit. These forces lines are called “magnetic flux”.

Flux Density (β)

Flux density is the number of lines of magnetic force per unit area, Gauss or Tesla is the measurement unit of flux density. Flux density is given the symbol “β” (beta).

Magnetizing Force (H)

Magnetizing force is the strength of the attraction or repulsion of a magnet, measured by counting the total number of magnetic force lines of the magnetic field. Magnetizing force is given the symbol “H”.

Magnetic Permeability (µ)

Based on a theory called “Magnetic Domain Theory” that assumes any material contains within itself small independent particles that exhibit a north pole and south pole, each particle from those is called “Magnetic Domain”.

The domains are arranged in a random direction in an unmagnetized material on which the magnetic fields for the domains cancel each other. When applying a magnetic force to the material, the magnetic domain tends to align themselves with the magnetic force and the material will exhibit overall polarity which is equal to the sum of the combination of all magnetic domains. How easy the domains can align themselves is called “Permeability”. Magnetic Permeability is given the symbol “µ” (mu).

High permeability material is the material that its domains align easily under low magnetizing force. In contrast, low permeability material is the material that its domain resist alignment even under high magnetizing force “Paramagnetic Materials” or rotate to positions that are 90°to the direction of the applied magnetizing force creating very slight repulsion “Diamagnetic Materials”.

Permeability is calculated by dividing flux density by magnetizing force.

µ = β/H

Magnetic Reluctance

Magnetic reluctance can be visualized as the resistance to the establishment of a magnetic field; the magnetic flux tends to follow the path with the minimum magnetic reluctance.

Magnetic Saturation

Material Magnetic saturation is when the material reaches to the maximum value of flux density that it can sustain. And in this case, the material is called “saturated”.

Hysteresis

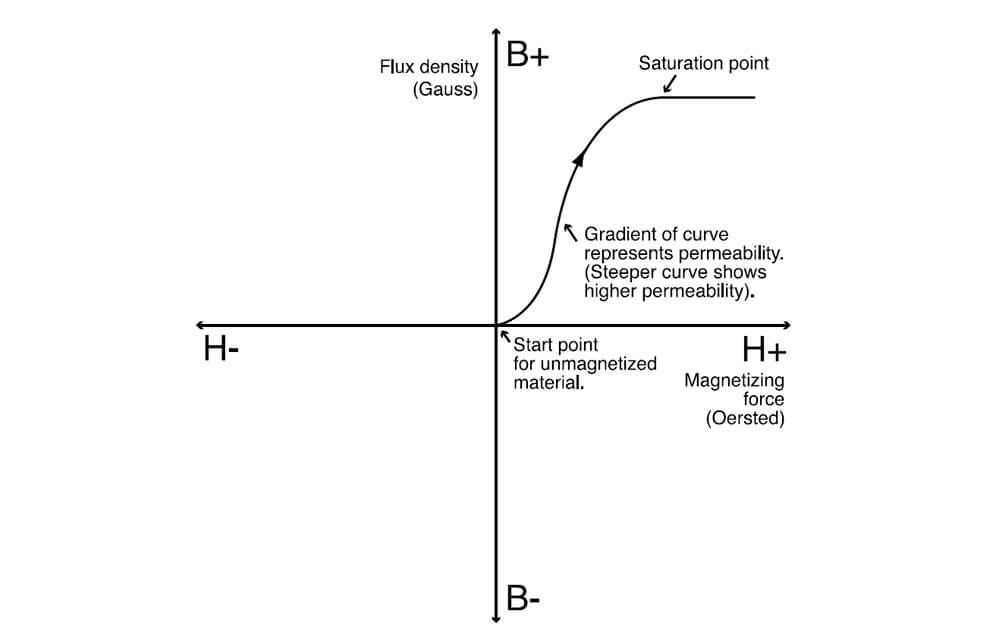

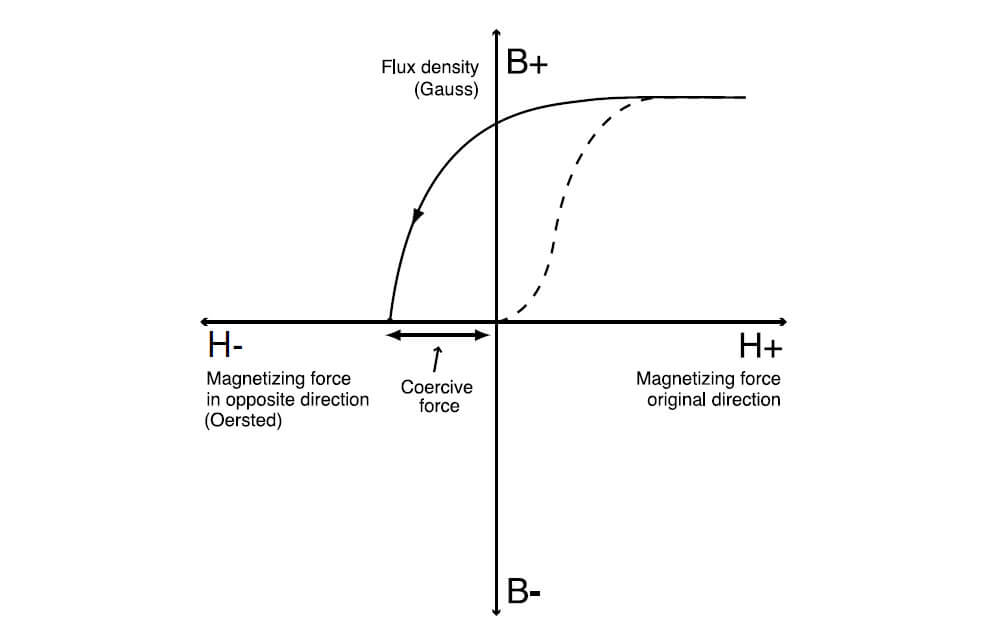

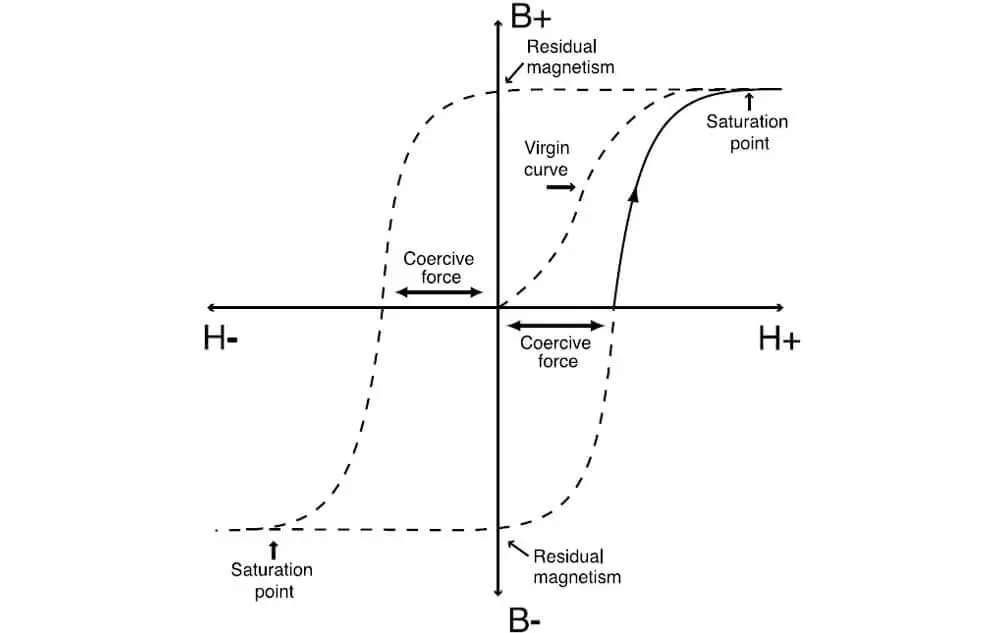

Hysteresis describes the variation on magnetic material flux density resulting from the change on the magnetizing force. The following graph represents how flux density increases with an increase in the magnetizing force.

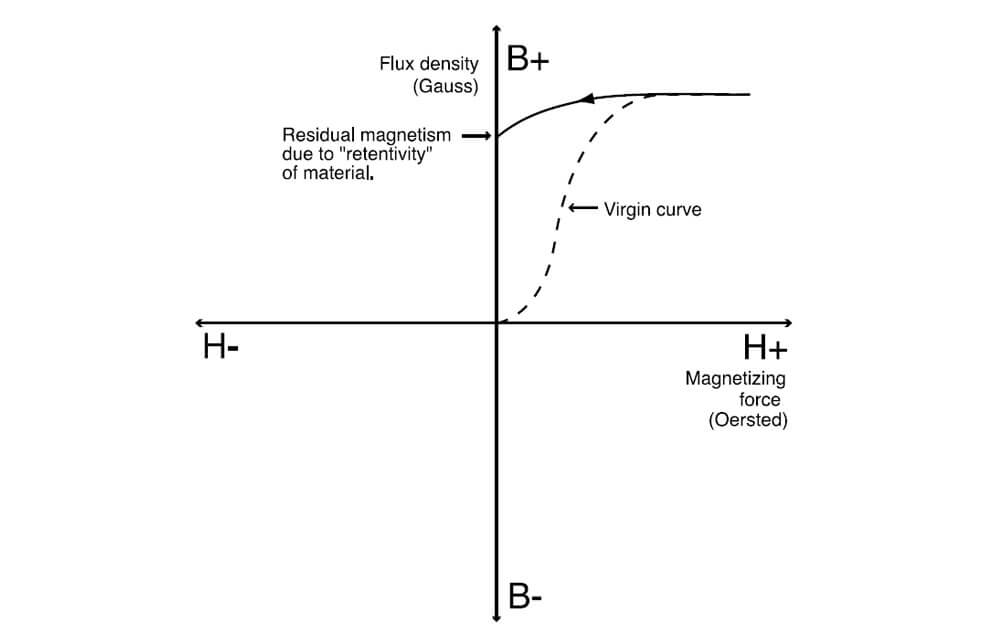

From the above graph, initially, the minor magnetizing force has produced a high flux density, this initial curve is called “virgin curve”. The curve changes in gradient toward the top and then flatten out at one point. Further to this point, any magnetizing force increase will not produce an increase in flux density. This condition is called “saturation”.

When decreasing the magnetizing force, it will produce a corresponding decrease in flux density. Upon reaching the point the magnetizing force is zero, it is noticed that still there is a positive flux density in the material. The retain of some flux density “residual magnetism” is due to the phenomenon called “retentivity” of the material.

The amount of magnetizing force initially applied, and retentivity of the material will determine the amount of residual magnetism.

By applying opposite magnetizing force, the flux density will reduce. Coercive force is the amount of opposite magnetizing force to reduce the flux density to zero.

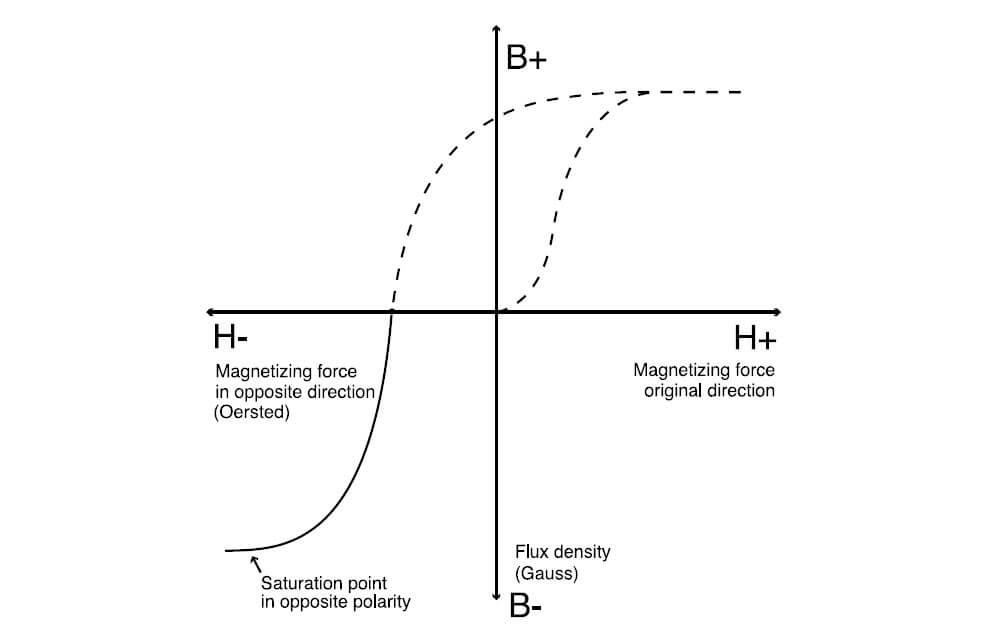

By increasing the opposite magnetizing force beyond the coercive force, the material exhibits a flux density flowing in the opposite direction.

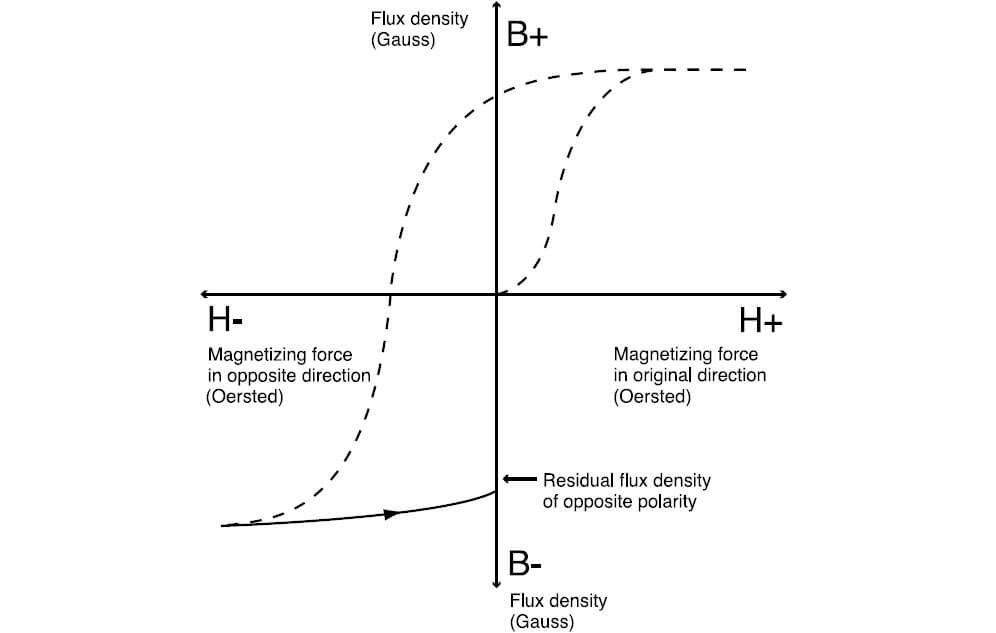

Upon reducing the opposite magnetizing force back to zero, the flux density will reduce, but again, some flux density will be present even when there is no magnetizing force applied.

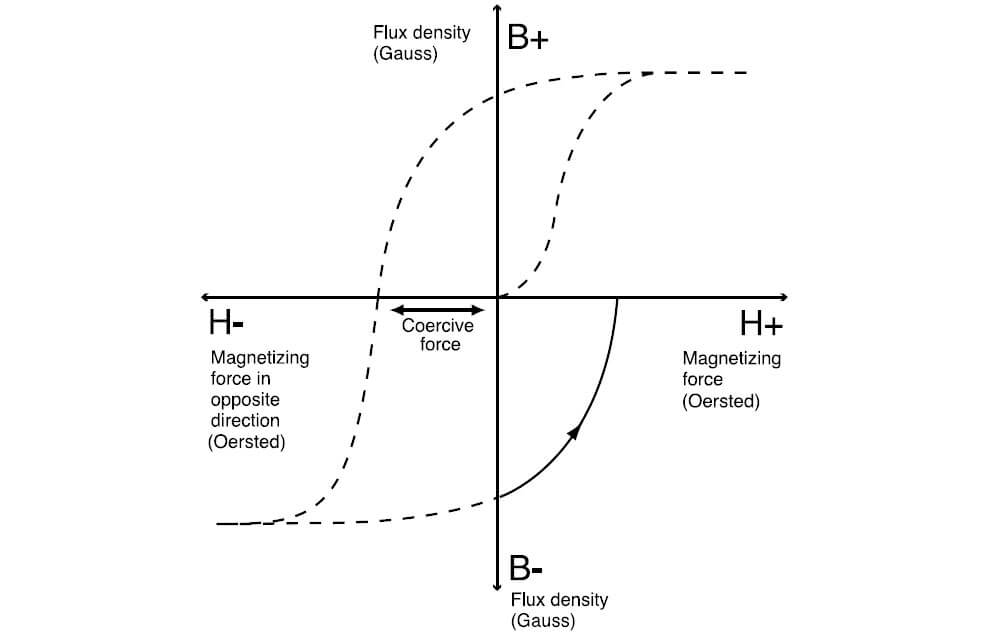

To bring the flux density to zero and to eliminate this field, magnetizing force in the original direction must be applied. Again, coercive force is the amount of magnetizing force to reduce the flux density to zero.

Increasing the magnetizing force once again will produce an increase in flux density until saturation in the original direction, this completes the loop which is known as the “hysteresis loop”.

Magnetization

In lights of the hysteresis loop, by placing a powerful permanent magnet closer to or farther away from the object getting magnetized achieving increasing and decreasing of magnetizing force. Magnetization or negative magnetization were accomplished by orientating the powerful permanent magnet.

Another method to produce magnetism is by electrical means. When electrical current flows through a conductor, magnetic flux will produce that flows around the conductor at 90° to the direction of the electric current flow.

Demagnetization

Ferromagnetic materials usually retain some residual magnetism after the magnetizing process. As previously discussed, the amount of magnetizing force initially applied, and retentivity of the material will determine the amount of residual magnetism. Complete demagnetization is difficult if not impossible to obtain; hence, the demagnetization process is limited to reduce the residual field to an acceptable level.

Demagnetization methods are based on subjecting of the magnetized part to continuously reversing magnetic field that gradually reduces in the part. It can be performed using a reversing DC field; however, AC is preferred by gradually reducing the applied current to zero or to passing the part through an AC demagnetizer.

The second method to demagnetize the part is by heating it to a temperature above its curie point and keep it to cool without any magnetizing force acting upon it. For this method, the residual field will be removed entirely, and the part will be completely demagnetized; however, it is not a practical method.

When is Demagnetizing needed?

Demagnetization may be necessary for the following reasons:

- The part will be used where a residual magnetic field will interfere with the operation.

- The part will be machined, and chips may adhere to the surface being machined.

- Foreign particles may attract to the magnetized part and cause mechanical damages during operations.

- The part will be welded, and Arc blow may be caused due to the residual magnetic fields.

When is Demagnetizing not required?

Demagnetization may not be necessary if:

- Parts are made of soft steel having low retentivity on which it will usually become demagnetized once they are removed from the magnetizing source.

- The parts are subsequently heated above their Curie point.

- The part is to be remagnetized for any reason.

References:

ASNT NDT Level III Guidebooks.

ASM International Non-Destructive Testing Books.