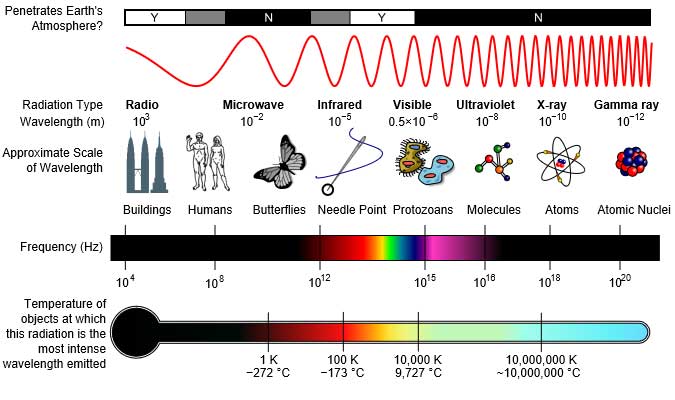

Blacklight (or Ultraviolet Light “UV-Light”) is electromagnetic radiation with 320-400 nm wavelengths. Blacklight lamp emits long-wave UV‑A radiation and little visible light. These lights are used in applications in which extraneous visible light must be minimized, mainly to observe fluorescence, the colored glow that many substances give off when exposed to UV light.

Typical blacklight units used in nondestructive inspection provide an intensity of 1000 micro-watt/cm2 at 15 inches from the face of the blacklight filter. They are used to excite fluorescent penetrant or magnetic particle solution in a range visible to the eye.

What Is Blacklight?

The human eyes can see visible light in the spectrum ranging from red to violet. The light above violet is ultraviolet light. Therefore, human eyes cannot see. However, we see its effects on our skin, such as sunburns and suntans. The blacklight bulb is the type of bulb that produces Ultraviolet-A light. When we turn on a blacklight bulb in a dark room, the bulb produces a purplish glow associated with ultraviolet light that we do not see.

Ultraviolet (UV-) light is electromagnetic radiation with a wavelength ranging between X-rays and visible light. The ultraviolet range is divided into three bands:

- Ultraviolet-A (UV-A), “A” band ultraviolet is a soft ultraviolet or long wavelength (320 to 400 nm), commonly called “blacklight.” UV-A has the smallest bandwidth of the ultraviolet range.

- Ultraviolet-B (UV-B), “B” band ultraviolet is a medium wavelength (270 to 320 nm) used for examining minerals and in suntan lamps.

- Ultraviolet-C (UV-C), “C” band ultraviolet is a hard ultraviolet or short wavelength (4 to 270 nm) used in germicidal or sterilizing lamps.

The source of ultraviolet light is often a mercury arc bulb with a filter. The bulb emits various wavelengths; however, the bulb filter allows ultraviolet light (320-400-nm wavelength) and a minor amount of visible light of the short wavelengths and suppresses the transmission of visible light of the longer wavelengths.

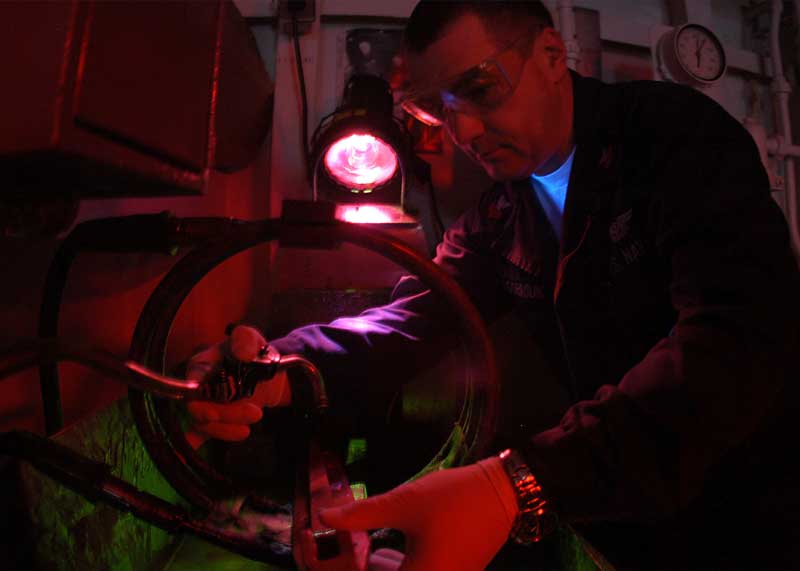

Nondestructive Testing Inspection Blacklight (UV-A Blacklight)

Blacklight bulbs are operated with filters and should not be used without filters. These filters have to be free from cracks, chipped pieces, or any other defects. A high pressure, mercury vapor, blacklight bulb, which is the common type used in NDT, requires a housing, filter, regulating ballast or transformer, and connecting cables or wires. The housing, which may be metal or plastic, hold the bulb and filter and prevent leakage of unwanted visible light. Most UV light must be warmed up for at least 15 minutes before performing the inspection.

The filter is a special material that prevents the passage of short wavelength ultraviolet and long-wavelength visible light. The filter transmits ultraviolet between 320 nm and 400 nm for the inspection requirements. The UV wavelength between 320 nm and 400 nm causes maximum fluorescence of the penetrant dyes.

Ultraviolet light is electromagnetic radiation and is measured in units of energy per time. Digital radiometers are the most commonly used instrument measuring UV light intensity. Radiometers typically measure the energy of ultraviolet light in units of energy per time per area. The minimum accepted UV-A output intensity for a blacklight is 1000 micro-watt/cm2 measured at a distance of 15-inches (38cm) from the outside face of the filter.

It is essential to keep white light output to the minimum; the white light reduces the inspector’s ability to detect fluorescent indications. Most procedures require white light levels to not exceed 2 ft-candles (22 lux) as measured with a white-light meter at a distance of 15-inches from the lamp filter. Blacklights that do not meet this requirement shall be disposed of.

Most standards and procedures require verification of filter condition and light intensity before conducting the nondestructive testing inspection.

Related Article: A Guide To Penetrant Test Classifications.

Blacklight Hazards

Prolonged direct exposure of hands to the filtered blacklight main beam can harm the skin and eyes. Prolonged exposure can cause painful sunburn, accelerate skin wrinkling and increase the risk of skin cancer. Besides, injury to the eyes and skin will occur if the light from the mercury vapor bulbs is not filtered.

Individuals are generally unaware of the occurring damage during exposure to UV light as it cause no pain. However, the damage and injury occur after several hours of exposure, making UV light a great threat.

The temperature of some operating blacklight bulbs reaches 750°F (399°C) or more during operation. The bulb temperature also heats the external surfaces of the lamp housing and may cause severe burns when contacting exposed body surfaces. Therefore, extra care should be taken when using hot blacklights to not burn hands, arms, face, or other exposed body areas.

The blacklight operating temperature is usually above the ignition or flash point of fuel vapors. Therefore, blacklight should not be used in the presence of fuel vapors as these vapors will burst into flame if they contact the bulb.

Blacklight Safety Considerations

- Blacklight bulbs should be used with proper filters, the filters to be free from cracks, chipped areas, or ill-fitting filters. Any defective filler has to be replaced before using the lamp.

- Suitable gloves to be worn when exposing hands to the main beam.

- UV filtering safety glasses, goggles, or face shields must be worn all the time during the inspection time.

- Extreme care to prevent contacting the light housing with any part of the body.

- Avoid using blacklights when flammable vapors are present, the blacklight temperature is typically above the ignition or flash point of fuel vapors, and these vapors will burst if they contact the bulb.

- Avoid handling blacklights at the penetrant rinse station when washing parts because of electrical hazards present.

References:

Non-Destructive Testing Inspector’s Handbook.