Tugboats are a type of Support Vessel that helps maneuver large Cargo carriers and other vessels by pushing, pulling, or towing them. When a vessel enters a port or during berthing (parking next to a jetty) or trying to unberth or leave a port, the tugboats are often used to guide them through various stages. This is essential for ports with high traffic, restricted channel routes, or vessels carrying high-risk cargo. These are also dedicated to moving ships that are not in a condition for self-propulsion, such as dumb barges, oil rigs, and most importantly, grounded vessels, a nightmare for the marine industry.

Why are tugboats important?

It’s safe to say; tugboats are the shepherds of the marine world. Megaships will find it difficult to get into or out of ports without harbor tugboats in today’s maritime environment. As the sizes of ships have increased, so have the demands on tugs. Tugboats need two things to get their job started; a powerful engine to hit high bollard pull capacity and a special hull design that allows them to dig into the water to gain traction, essential to move monstrosities of 4000 to 400,000 GRT (Gross Register Tonnage).

Tugboats have GRT, which is a measure of load carrying capacity relative to the size and design of a vessel, in the range of 100-200 GRT. Tugboats often work in teams and work up to 500-1000 times their size. Tugboats may look small when sitting next to mega-ships, but they are all muscle and fancy footwork which help these giant carriers take goods in and out of the ports.

In general understanding, the effect of tugboats in the maritime industry is often undervalued; however, their contributions prove of paramount importance during rough weathers with higher sea states and in limited size ports. Without their strict support, a major cog in the shipping sector will be damaged, causing a domino effect on that region’s economy. These support vessels serve in both inland waterways channels and open seas. Tugs are designed to perform very specific functions that are in line with the unique requirement of the port/waters in operation and are thus categorized accordingly.

Types of Tugboats

1. Ice Breakers

It is designed with specialized hulls for clearing waters channels beset in ice by breaking them with hull impact or weight. These are ice-strengthened and have a specialized hull structure to sustain heavy damage and metal embrittlement. An ice breaker is a general class for any type of ship ice-strengthened. These tugboats preferably have a twin-engine screw propeller with a Kort nozzle. These often have lower freeboard due to the load of extra scantlings and are not suitable for complex maneuver operations.

2. Salvage/ Search and Rescue

These are typically bigger tugs with high-power pumps, specialized winches, etc., used to either salvage grounded ships or stabilize and prevent them from sinking. They also engage in emergency search operations for distress calls. Such tugboats have primary applications in dredging sites and emergency engineering services. Tractor tugs are the choice of the captains for such activities. Equipped with state-of-the-art safety items and specially trained crew.

3. Towing and workboats

These tugs provide emergency steering and braking functions to mainly large ships in oceans, ports, or critical coastal areas and other miscellaneous operations on ports and inland waters. The most common application tugboats are often designed to perform multiple functionalities. Capable for all towing, pushing, and maneuvering activities. Preferably ASD (Azimuth Stern Drive) propulsion systems are installed. Based on design philosophy as per application, they may be twin-engine powered.

4. Firefighting

Firefighting capability is installed and mandatory for every vessel as per SOLAS regulations; however, dedicated Firefighting tugs are equipped with high power pumps with hose lines and Fire retardant materials on board to extinguish all A, B, and C types of fire from a safe distance. Only qualified firefighting crew are allowed to operate such dedicated vessels. These may be stationed at a strategic location for the port (not all ports) to allow efficient access and rapid response timings in fire scenarios. These often closely work with Tractor tugs for emergency towing operations in busy port areas.

5. Anchor handling

Designed to deploy, relocate or retrieve anchors, which may weigh several tones. These are usually operated by Scuba divers or (in some cases) ROVs for hooking on anchors. Larger AHTS (Anchor-Handling Tug/Supply vessels), as they are commonly called, are used for drilling sites. Up to three engines may power these tugboats. They are often equipped with machinery and facilities for emergency activity since they work in deep water regions, miles away from the nearest emergency support. These work in coordination with other offshore support vessels (OSVs) at offshore oil and gas sites.

6. Yarding

These are smaller tugs used to move dumb barges (those barges that are not designed with a self-propulsion unit of any kind) for large towing in coastal areas or inland waters. These are equivalent to smaller workboats with modest propulsion and used for small-scale towing activities. Have very limited applications in larger ports with bigger vessels, where they may be used to ferry crew and pilots on board.

7. Line handling

These are the size of a small speedboat with very limited freeboard and hence specialized design. These may be powered by an outboard motor or a single screw propeller operated by a 2-3 crew. Line handling tugboats do not engage in active towing/pushing operations. Still, they act as a support vessel for larger tugboats to secure the hawser line of incoming ships to execute towing operations.

8. Survey and Research

Used for scientific and oceanographic surveys, including hydrographic surveys, aquatic/marine biology research, seismic activities, and oceanographic research. These tugboats are commonly known to have paces capabilities for executing continuous and extended operations in a wide array of environmental conditions. These are technically not classical tugboats but constructed under similar design principles. Survey and research vessels are usually equipped with high-value survey instrumentations (which may also be installed in a special contraption called Drop Keel) and state-of-the-art radar mapping systems.

9. Patrolling

These are high-speed craft primarily used by local police, harbor patrolling, disaster rescue operators, and coast guards. Patrolling crafts are often designed for high speeds of up to 25-40 Knots (unit of speed of marine vessels) and may be equipped with arms and ammunitions. A water-jet propulsion system may be installed (relatively costlier) for those with standard operating speed between 20-35 Knots as they generate maximum efficiency in that range.

10. Crew boats

These are designed to operate near coastal areas in shallow waters or for crew transfer at the oil field in deep waters. These primarily have large decks space and relatively higher GRT and are constructed in aluminum or marine steel depending on speed and duties. The crew boats have larger accommodation and gantry spaces for sustaining longer transportation. The boat is designed such that stability variables enable a comfortable ride.

The crew and work requirements also vary for each type of vessel. Many tugs are often designed to be deployed for more than one of these activities, thus are popularly referred to as a “Multi-Purpose” vessel.

Design and operations parameters of tugboats

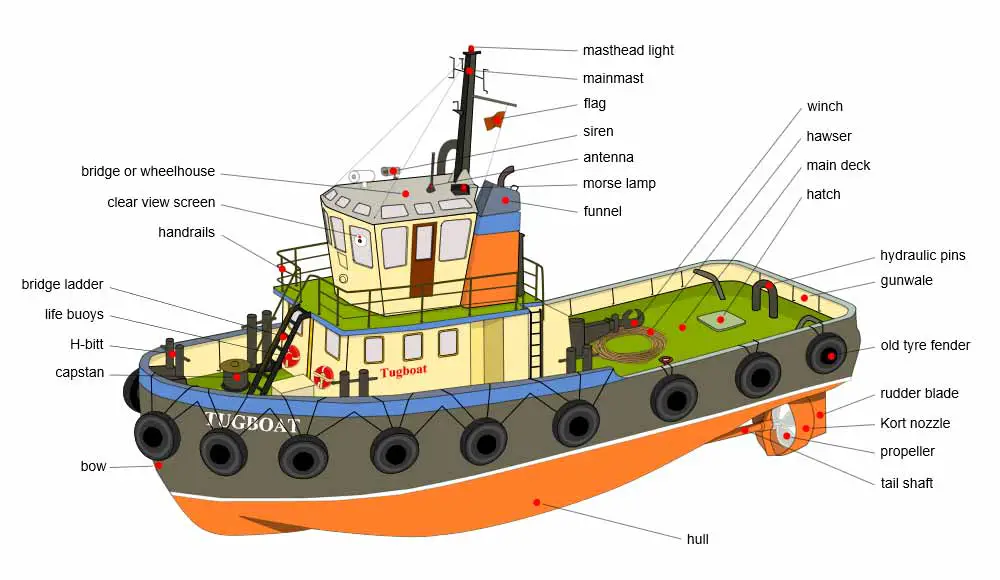

Compared to bigger commercial ships, Tugboats are much smaller in dimension and capacity as per design, but they are sturdier and more powerful boats. Most tugs pull a vessel with the help of the towing lines, a strong a sturdy laminated steel cable/Polypropylene (PP) rope, also known as a hawser, at very slow speeds and directionally controlled. If the river has strong currents or complex tide patterns, tugboats play a critical role in the safe passage for these ships.

The tugboats, in general, range in length overall (LOA, which is measures from tip to tip of fore and aft section of the ship) of 20 to 70 m. The construction material may vary between wood and metal. Metal fabricated constructions have heavy-duty hollow fenders made of rubber tires/ebonite/wood to generate cushioning effect for vessel hull interactions. Engines generate individual power of up to 500 to 3000 BHP. Based on design considerations, it may be single, double, or triple in number. In the early days of the tugboats, most engines were powered by steam. In modern times, they have been replaced by diesel or diesel-electric units. Any normal cargo and passenger ships have a Power to Weight (Tonnage) (P: T) ratio of 0.35-1.20. Machinery comprises up to 35% of total weight. Hence, Engines selection is always for a compact unit that can help deliver the highest Power to Weight (Tonnage) ratio of 2.20-9.50.

The bow and stern both have construction that allows the load during pushing to be absorbed by the hull so as the tug’s maneuvering and stability variables do not get adversely affected. The fenders for a tugboat are preferred to be high-abrasion-resistant rubber with high toughness and shock absorption properties. Often these are taken from large, heavy transportation machinery or aircraft tires which are rigidly knotted with PP ropes. These are specially fabricated with compression molded high-pressure thermic-fluid material and have excellent seawater resistance in certain designs. However, these are in consideration with costs to functionality. Other types of tugboat fender include Tug cylindrical fender, W fender, M fender, D fender, etc.

Basic applications and specialized duties

The main characteristic of all tugs, including the seagoing tugs, is that they have a very low deck line and hence very little freeboard, i.e., height between deck line and waterline. This brings the machinery and installations, including winches and bollards, very close to the waterline (or level). The same is necessary to ensure that the towing line, which is extended to almost midship of the vessel, has a high degree of freedom of movement to move about the point at which the two lines are attached tugboat. Also, this is an important variable to ensure the stability of the tugboat during operation since increasing the height of a towing point on the tug will move it further away from the center of gravity of the boat and propellers line of thrust, hence creating a torque.

The torque may lead to extreme heeling (tilting the vessel in one direction due to external load; in this case, the tension due to towing line) and even capsizing the tugboat. The towing winches are normally located at the midship so that the forces do not influence the boat’s maneuverability.

There is a type of towing by ‘Notch‘ where the tug can be secured in a notch at the stern of a vessel that has a specifically designed cavity. The bow of the tugboat locks on that notch and starts to push the vessel. The ‘Articulated Tug and Barge units, also called ATBs, also utilize mechanical mechanisms to connect to the respective barges.

There are also ‘Integrated tug and barge,’ which comprises specially designed vessels and locking points that lock together in a rigid and strong method. This ‘effectively’ merges both the hulls as a single unit of compound hull shape. The designs and operations during towing cases are to be separately certified as such by regulatory authorities.

Escort Tugboats are used to escort huge vessels along a narrow or dangerous channel. In the past, these facilities were provided only to massive ships whose own propulsion system is not capable of maneuvering in dangerous waters or restricted channels or narrow canals. However, as a result of series of accidents in the past that have led to adverse effects on marine and human life, this facility is now more frequently implemented.

Escort tugs have very high maneuverability power and comprise omnidirectional azimuth propellers. Such tugs are called Tractor Tugs, a relatively new type of vessel in response to the recent marine pollutions caused by the grounding of oil tankers. These hybrid tugs are driven by two marine diesel engines of approximately 3000 BHP, which are independently driving a pair of azimuth propellers, both independent in operation and control. Precision-tuned with computer monitored fuel injection and turbochargers, each one of these engines could power a full-size locomotive. These tugs ride low under the enormous weight of their engines, and as these power-up, they sink even further. This is due to a specific type of hull design implemented called ‘heavy displacement hull.’ The hulls have a higher wetted surface area due to underwater keel, which increases friction and helps them gain traction in the water. The Tugs take the point at clearly marked sweet spots on the vessel and gently push the freighter.

Apart from helping large vessels achieve controlled movement in narrow regions, these tugboats attend to ships and guide them through narrow harbor entrances with efficient and complex maneuvers. They often act as aquatic emergency brakes. The high power winches of up to 250BHP and strong towing lines come in handy for performing their’ most advanced maneuver’.

It starts by hooking up to the centerline at the stern of a ship. The tug then moves out to one side. With the help of their powerful azimuth drivers and support from the bow thrusters on the ship, the Escort tugs rotate the ship like a giant rudder pivoting around its midship at the same spot. This turns the vessels 10 times faster than it ever could with a simple push.

Some tugboats are also known as ‘Push boats.’ A Push boat is like a square ball with very large fenders around its sides. The boat essentially sits flush to the side of a ship and pushes with its thrust. A variation of their use in inland waters is also in the form of tying the side bollards on both vessels with a PP rope and then towing the ship/barge in a suitable direction with their azimuth propellers. This is essentially useful in rivers with high current and restricted areas.

Factors affecting duties and activities of a tugboat

Every port has its own set of requirements and daily activities which are designated to these tugboats. The primary function is pushing or towing mega-ships or dumb-barges. Their duty calls are dependent on the following factors:

- Port traffic volume,

- Types of ships to be served by that tug,

- Navigational obstacles to be catered,

- Conditions of environmental protection,

- Local laws, and,

- Domains to be carried by a tug.

This allows them to often work in pairs or teams. Other specialized activities are specific to the activities carried out by that type of tugboat, as stated previously.

Tugboats propulsion systems

The first tug boat, Charlotte Dundas, was built by Mr. William Symington in 1801, which was powered by a steam engine and paddle wheels and was used on rivers in Scotland. We have come a long way since that to modern tugboats with advanced machinery and propulsion technologies in place. Following are the most popularly used propulsion systems among tugboats:

- Conventional screw propeller with Kort nozzle: an open-ended annular foil-shaped channel used to accelerate the wake through a conventional propeller –rudder system, thus generating more thrust than a comparable open propeller.

- Z drive (ASD) or Azimuth Stern Drive: steerable propulsion units can be rotated through 360 degrees with a screw propeller-driven through two right angle gears. This system is also found in Retractable Arrangements. ASDs have a much-improved bollard pull per kilowatt and have better maneuvering capabilities than the Kort-nozzle system, hence the most popular and affordable (as long as the system is not damaged and has to go for repairs).

- Voith-Schneider (VSP): a cycloidal propeller comprised of a rotating circular plate in the vessel’s bottom from which a number of vertical foil-shaped blades project downward. These blades are cyclically pitched twice per revolution to produce force (thrust or lift) in any direction normal to the axis of rotation.

These may be single or dual propulsion units placed according to application and functionality. Dual systems with a combination of the left-hand and right-hand screw propellers stabilize the tugboat’s lateral movement due to lateral load on thrust blocks (a specialized mechanical component that transmits the force generated from propellers onto the hull). These propulsion systems individually have their advantages and disadvantages and are selected based on the applications and primary function of the tugboat. Factors such as efficient movement in six degrees of the ship’s motion, trimming during towing, sensitivity to interaction with other ships, etc., are considered during the process.

Each port has its particular features which determine the way the tugboats are used. The following conditions are crucial when these are being chosen and used:

- The volume of traffic in the ports.

- The types of ships serving the port.

- Navigational obstacles were found in the port.

- Conditions of Environmental Protection and local laws apply.

Sample specifications of a Tugboat

Marine vessels have hundreds of parameters defining their specification. Tugs are no different. When designing or exploring a tug boat of any type, it is useful to be aware of some of the parameters that define that tug’s design specifications, operations, and functionality. An example of such parameters or a sample Tugboat design is given below:

Please note that this information is for EDUCATIONAL PURPOSES ONLY and should not be applied for commercial applications without consultation from an experienced team of Naval Architects.

1. Main Design particulars

- Length overall: 25.90 m.

- Length between perpendiculars: 23.10 m.

- Breadth, molded (excluding hull thickness): 6.80 m.

- Depth, molded (excluding hull thickness): 2.80 m.

- Draft, molded (excluding hull thickness): 2.10 m.

- Gross tonnage (GRT): 120 tons.

- Service speed (v): 12.0 knots.

- Cruising radius (R): 1,290 sea miles. Max. Bollard pull (the maximum thrust which can be generated by a vessel at zero speed (usually measured by pulling on a “bollard”). This is the typical measure of tugboat performance: more than 205 KN.

- Complement 9 persons (6 berthed and 3 unberthed).

2. Capacity

- Fuel oil tank: 25 m3.

- Fresh water tank: 13 m3.

- Main engine: 588 kW x 900 rpm x 2 sets.

- Propeller: 4 blades fixed pitch in steerable Kort nozzle.

- Flag: Panama.

- Classification: ABS.

3. Deck machinery

- Windlass Electric: 14.7 KN.

- With center drum: ____ mmφ x ____ m tug-line, slack line pull.

- Capstan Electric: ____ KN x ____ m/min x ____ set.

- Steering gear Electric hydraulic: ____ KN x ____ set.

- Crane Electro-hydraulic, foldable jib type: ____ set ____ KN Safe Working Load x ____ m radius; max radius of about ____ m.

- Towing hook Manual release: ____ KN SWL x 1.

- Towing beam: 1.

- Towing bit.

4. Lifesaving apparatus

- Life raft Inflatable, for 9 persons x 1.

- Life jacket 13 (9 for personal use + 4 for duty crew).

- Radio LSA Two-way VHF Tran receiver x 2, EPIRB x 1, SART x 1.

- Dinghy _____ m rubber/FRP composite type with about _____ KW.

- Outboard motor.

- Other Life buoy, distress signal, etc. according to the rule.

5. Firefighting apparatus

- Fire hydrant 2 positions (deck and engine room).

- Portable extinguisher Powder type.

- Fire monitor manually operated, 500 lit/min.

- Pump for above 35 m3/h x 50 m (driven by harbor generator).

6. Accommodation

- Crew’s room.

- Berth cabin.

- Galley.

- Mess room with TV and video.

- Shower room.

7. Ventilation.

8.Engine room machinery

- Main engine: 4 stroke cycle medium speed diesel engine.

- MCR: 588 kW x 900 rpm x 2 sets.

- Gearbox.

- Propeller: (Blades and type).

- Main generator: AC 225V, 50Hz, 50kVA x 1 set Driven by 45 kW diesel engine.

- Harbor generator: AC 225V, 50Hz, 30kVA x 1 set Driven by 28 kW engine.

- Main air compressor.

- Engine cooling system.

- Main cooling.

- Standby LO pump.

- FO transfer pump.

- Bilge/GS/fire pump.

- Fresh water pump.

- A/C cooling water pump.

- LO filter: CJC type x 2.

- Water separator: 1.

- Sewage tank: about 1 m3, with sewage discharge pump.

9. Inboard communication

- Engine telegraph: 2.

- Common battery telephone: 5 lines x 1 (wheelhouse, mess room, crew’s room, engine room and steering gear room).

- Public addressor: Amplifier, speakers.

- Alarm system: 1 set.

10. Navigation and Communication aids

- Magnetic compass: 1.

- Steering control: 1 (magnetic compass auto pilot).

- Radar.

- Echo sounder.

- Weather FAX.

- GPS.

- Air phone.

- Searchlight.

- Window wiper.

- Clear view screen.

- Other aneroid barometer, binoculars, etc.

- International VHF radio.

- MF/HF SSB radio.

- Walkie-talkie.

11. Rules to apply

- Classification Society’s rules.

- Local Shipping Act.

- International Maritime Code.

- Others as applicable.

Final thoughts

The next time you are visiting a Tugboat, I hope you will have some idea of important things to note and critical components to look out for. The sample specifications should give an idea of the parameters suitable for the type and size of the vessel in question. Now, it will not be mere sightseeing but an informed process.