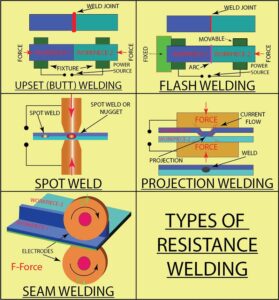

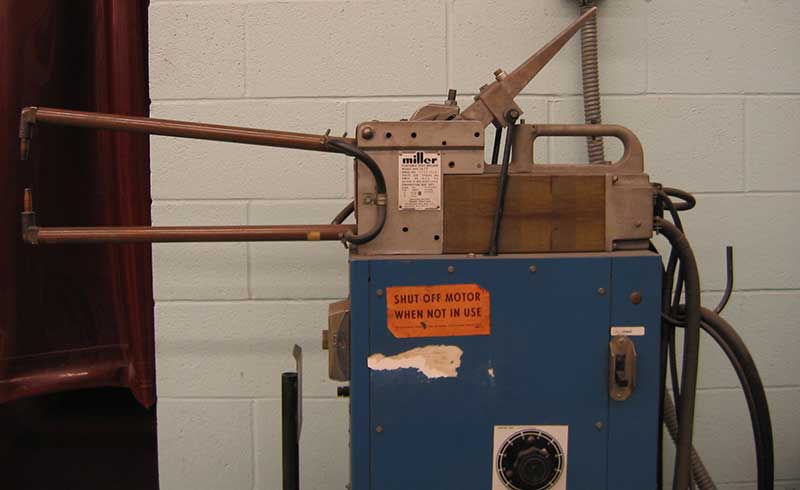

Resistance welding or electric resistance welding (ERW) is the welding process that joins metal parts in contact permanently by heating and melting them at the joint utilizing an electric current. The electric resistance welding process can be classified by the geometry of the weld and the method of applying pressure to the joint: spot welding, seam welding, flash welding, projection welding, upset welding, flash welding, percussion welding, and high-frequency welding.

What are the types of resistance welding?

Different types of resistance welding are:

- Spot welding.

- Seam welding.

- Projection welding.

- Upset welding.

- Flash welding.

- Percussion welding.

- High-frequency welding.

1. Resistance spot welding

Spot welding can be used for joining two or more overlapping metal sheets. The electric current, pressure applied, and the shape of the electrode is dependent on the thickness and type of the metals to be welded. The metals to be joined should have a clean, smooth, and flat surface. The shape of the electrodes helps localize the current and heat generation to the point of welding. The size of the weld nugget (weld joint) depends on the contact area of the electrodes.

The metal workpieces to be spot welded are held between the two electrodes. The individual spot welds are made by the momentary application of current and pressure into the metal workpieces. The current passed at the contact point generates thermal energy to bring the metal in the weld area to the plastic form, and the electrode pressure fuses the metal to form the weld. Spot weld between two sheets is elliptical in shape, and they can be overlapped to make the weld continuous.

Application of spot welding

- Spot welding is extensively used for the joining of automobile sheet metal bodies and large parts.

- Spot welding finds wide application in the manufacture of furniture and domestic equipment.

- Joining the metal handles to metal utensils and buckets.

- Manufacture of nickel-cadmium cells.

- Dental and medical instruments manufacturing.

- Manufacture of metallic toys.

Advantages of spot welding

- Optimum use of electrical energy, low workpiece deformation, good production rate, high adaptability to automation, joining of dissimilar metals, and no need for filler metal.

- Spot welding has a high shear strength compared to the riveting process.

Disadvantages of spot welding

- Spot welding does not give a continuous weld seam, and hence it is inferior compared to weld joints produced by other welding processes.

2. Resistance seam welding

In resistance seam welding, a continuous seam welding of overlapping metal workpieces is generated by continuous overlapping spot welds. The seam welding happens progressively (starting from one end and ending at the other end). This process can be used to produce liquid or gas-tight vessels (gasoline tanks) and automobile mufflers. The overlapping metal sheet is passed between the electrodes and made to undergo timed pulses of current to form overlapping spot welds. The electrode applies the necessary force for the welding. The timing of the spot weld and the movement of the overlapping metal sheet are to be perfectly correlated (controlled) to ensure perfect overlapping of spot welds and not overheat the workpiece.

The welding current used in this process is higher than the normal spot welding, and external cooling of the work metal (by air or water) is employed to compensate for the short circuit of adjacent spot welds. Another variation of this process is to pass the overlapping metal between the two current-carrying rotating (roller shape) electrodes. Continuous seam welding is produced in this process by controlling the movement of the work metal and the rotating electrodes. The rotating electrodes apply the required pressure on the work metal. This process for the thin sheet metals can achieve a working speed of 60 inches per minute.

Types of seam weld joints are:

- Lap seam weld.

- Mash seam weld.

- Metal seam weld.

Mash seam type of resistance welding is used to produce butt weld between thicker metal plates. This process utilizes the electrical resistance of the butting metals to generate the required heat. A high-frequency current up to 450 kHz. It is utilized to confine the flow of current to the location of the joint and its surroundings. The high-frequency current combined with superior welding speed limits the heat-affected zone.

A resistance seam welding produces a highly durable weld since the forge welding is due to the heat and pressure applied by the electrodes. The strength of a properly executed seam weld can far exceed the strength of the metal workpieces. A very common application of seam welding is for the manufacture of round and square cross-section pipes.

3. Resistance projection welding

You can call projection welding a form of modified spot welding. Here, one of the metal workpiece surfaces has one or more small projections in the form of a round male dimple, ridge, or ring and the location of the projection is in the area where the weld is desired. The metal workpieces are placed between the electrodes with a wide area. Current and pressure are applied similar to the spot welding process. Since the current has to flow between the points of contact (projection), the heat or thermal energy gets concentrated in the area where the weld is desired. The metal in the weld area turns into a plastic state, and due to the electrode pressure, the projection gets flattened and forms the weld.

In dissimilar metals, it is preferred to have the projection on the metal with lower electrical resistance. Normally the projections are formed by a press operation as this can be easily made a part of other blanking and pressing operations of the part (hence no additional cost to create the projection).

Advantages of projection welding

- Projections can be made in various shapes like dimple, ride, ring, or any particular shape to suit the part design.

- By creating multiple projections on the metal workpiece, multiple welding can be done simultaneously in one stroke.

- By modifying the size and form of the electrode, the regular spot welding machine can be converted to a projection welding machine for a particular part.

- Projection welding does not leave a mark on the top surface of the metal workpiece; hence the top surface retains its original finish (this is a clear advantage over spot welding since spot welding leaves a burnt mark).

Application of projection welding

- A projection that is machined or forged in the bolt and nut can be used for projection welding.

- Projection welding is highly suitable for mass production automation.

- Simultaneous multiple welds can be made using additional pressure.

- Projection welding is regularly used for resistance welding of nuts, studs, or other threaded parts onto a metal machine part.

- This process can be used to join two crossed rods or wires. Two crossed socket spanners welded together using resistance projection welding are very popular with automobile maintenance mechanics.

- Resistance projection welding finds its application in automobiles, electrical, electronics, and items used in the construction industry and for manufacturing valves, pumps, etc.

4. Resistance upset welding

In upset welding, the two metal workpieces to be joined are placed together in the form of a butt joint. The two workpieces are held together under pressure, and the current is applied at the contact area of the workpieces to generate heat. Due to the intense heat and pressure, the two workpieces get fused at the joint with little upset (bulge); hence the name upset welding. Upset welding can be used to join two rods or plates of the same cross-section.

Continuous seam welding is a variation of upset welding, and this technique is used to manufacture electric-resistant welded pipes (ERW pipes). The process of butt (upset) welding is used in the manufacturing of railway track joints, wire and rod joints, and wheel rims.

5. Resistance flash welding

Flash welding is similar to upset welding; however, the required heat for melting is generated from an arc instead of normal resistance heating. There are two platens on the machine (one is movable, and the other is fixed), and the two metal workpieces to be welded are fixed on these two platens. The faces of the two metal workpieces should be parallel to each other. The two metal workpieces are moved to butt against each other, and the electric current is switched on.

The two work metals are separated momentarily to create an arc and melt the ends of both the work metals. The two work metals are again brought together, the electric current is switched off, and the two ends of the work metals are fused under force. The melted metal flows out of the joint to form a flash around the joint. Flash welding is normally faster than upset welding and can be automated using an arrangement of cams.

6. Resistance percussion welding

Percussion welding uses the heat generated from an arc produced by the quick discharge of electrical energy to join metals. The electrode pressure is applied gradually, either during or immediately after the electrical discharge. This process resembles flash or upset welding. The machine used for percussion welding can be magnetic or capacitor-discharge, and it normally comprises an altered press type resistance welding machine with customized transformer, controls, and electrodes.

7. High-frequency resistance welding

High-frequency resistance welding weld the metals using the heat generated from the electrical resistance of the metal workpieces by adopting an alternating current with very high frequency (can be 10000 or more hertz) and by rapidly applying an upsetting force after heating. High-frequency resistance welding is a completely automated process, and the equipment is custom designed.

The advantage of high-frequency resistance welding (HFW) over low-frequency resistance welding (LFW) is very clear; the heat-affected zone (HAZ) in the case of HFW is very narrow (compared to LFW), and hence the flow of current and heat is restricted to a small area.

Other variants of resistance welding

Single-sided or one-sided resistance welding – This is a special resistance welding process in which a spot weld is made using only one electrode from one side of the welding, and there may or may not be a backing plate. This process uses less welding force and is hence limited to the welding of thin sheets only. This can be useful for welding parts that do not have access to accommodate electrodes from both sides.

Crosswire welding – A mesh of wires or rods can be joined at cross joints by applying direct pressure and current to the joint by using the electrodes, and normally flat-faced electrodes are used. The current and the generated heat are localized to the cross joint. Crosswire welding finds its application in the electrical industry, construction industry, and in the manufacture of metal wire kitchen racks and shopping trollies.

Indirect spot welding – Indirect spot welding is a special process where the spot weld is made with one electrode located directly on the welding spot. The other electrode is located at a little distance and offset and conducts the electric current through the metal workpiece.

Stud welding – A variant of resistance welding known by the name stud welding is used to weld studs, bolts, and bosses onto the oil tanks used for hydraulic applications. Stud welding is fast, reduces operation time, welding joints are uniform, and the process can be automated.

Related Article: Insider’s Guide To Electric Resistance Welding (ERW).

References