Quality control in welding activities is of utmost importance. In this regard, the Fillet Weld Gauge proves a critical tool within a welder’s kit. This tool allows for quick and efficient inspection of your welds. Its primary function is to measure the size of a fillet weld, which is essentially the triangular weld bead resulting from two pieces of metal joined by welding.

A Fillet Weld is a specific type of weld joint used for welding two base metals that are either perpendicular or at an angle to one another. The cross-sectional visualization of the weld takes on a triangular shape. Fillet welds are versatile and can be used for welding two base metals in shapes such as ‘T,’ ‘L,’ or even a lap joint. These types of welds are commonly deployed in structural fabrication, general fabrication, construction, etc.

Measurements that can be taken using a fillet weld gauge include the throat and leg length, often the most common dimensions inspected. Some fillet gauges even offer the capability to check the concavity or convexity of the fillet weld.

Brief about the Fillet Welds

When inspecting welds visually, using a fillet gauge to determine the acceptability of a fillet weld is essential. By identifying deviations early on, corrections can be made by reworking the weld, which is often possible. Using a fillet gauge helps ensure the weld is up to standard.

The cross-section of a fillet weld resembles a triangle, and the welding symbol for a fillet weld with equal legs shows a triangle (with two equal sides) as the cross-section of the fillet weld.

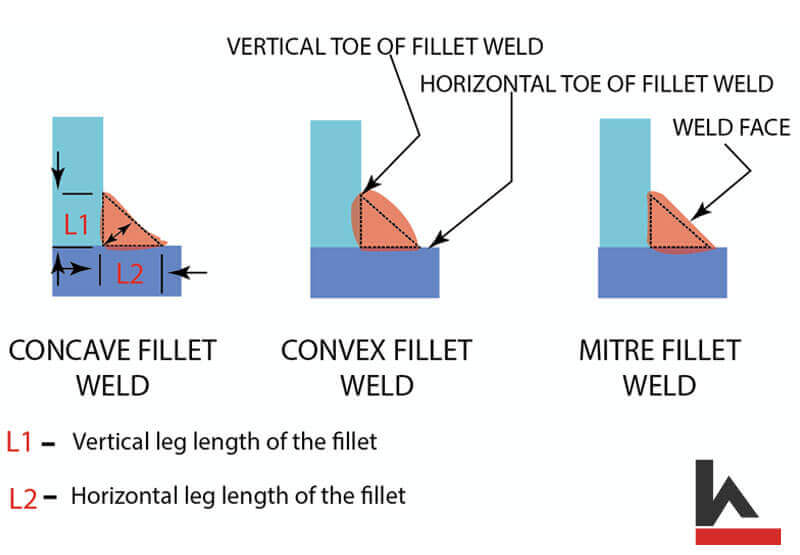

However, the actual cross-section of a fillet weld can have a convex or concave face or flat face. The different types of fillet welds are:

- Convex fillet weld.

- Concave fillet weld.

- Miter (flat) fillet weld.

Fillet weld is specified in the welding drawing by its leg or throat size. The sizes of the two legs can be equal or unequal. In AWS (American Welding Society) standards, the fillet weld is specified by its leg length (sometimes both leg length and throat). But in ISO (International Standards Organization) standards, the fillet weld is normally specified by its throat.

The Leg Length of the fillet weld is the distance between the root and toe points, measured in both directions (vertical and horizontal). The two leg lengths of the fillet weld can be equal or unequal.

The Throat of the fillet weld is the distance between the intersecting point of the two legs (root), and its face and throat are measured across the cross-section. The length of the leg and the throat in an equal leg fillet weld has a relationship, and you can calculate the throat by multiplying 0.707ʺ × fillet leg length.

Types of Fillet Weld Gauges

Fillet gauges are designed based on their leg sizes. The length of the vertical and horizontal leg should conform to the fillet weld specification; otherwise, the strength of the fillet weld is compromised.

The fillet gauges can be of two types:

1. The Template Type Fillet Gauges

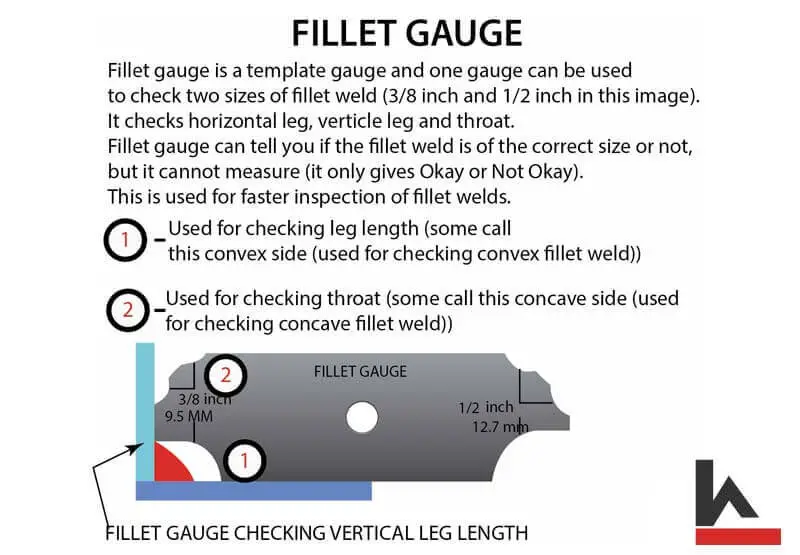

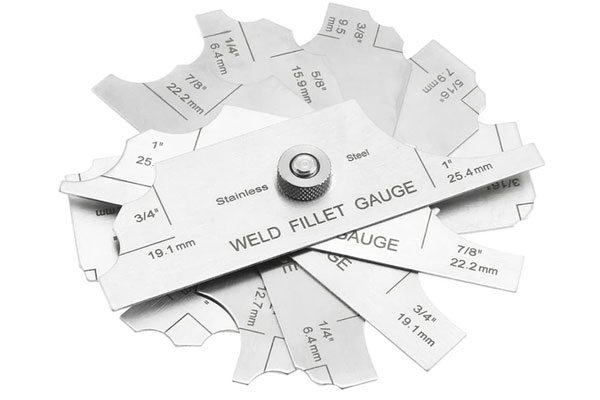

The first type of fillet gauge is like a template normally made from a stainless steel sheet. The template type fillet gauges are available for each size of a fillet weld, and these gauges can be used for declaring the weld as okay or not okay, but they cannot measure the leg length or throat.

These gauges come in a set of 7 or 8 different sizes, such as 1/8ʺ to 1ʺ, 1-1/8ʺ to 2ʺ, and 2-1/8ʺ to 3ʺ. It is fast and easy to use this fillet gauge, and the welder or the inspector can quickly check the weld size and declare whether it conforms to the specified fillet size. The welder can use this gauge to check and reweld the undersized welds.

2. Adjustable Fillet Weld Gauge

The second type of gauge is called ‘adjustable fillet gauge,’ and the word adjustable means this fillet gauge can be set to the required size of fillet and can then be used as a normal template type fillet gauge, or you can measure the fillet weld size (both leg length and throat).

In a nutshell, the adjustable fillet gauge can be used for measuring the actual dimension of the leg or the throat. Another advantage of the adjustable fillet gauge is that it can also measure the fillet welds of unequal leg length.

How to Use a Fillet Gauge (Template Type) to Measure Fillet Welds Size?

Checking Leg Lengths

To check leg length, first, select a fillet weld gauge that meets your required specification. And verify the fillet weld joint specification; note down the nominal size of the fillet weld.

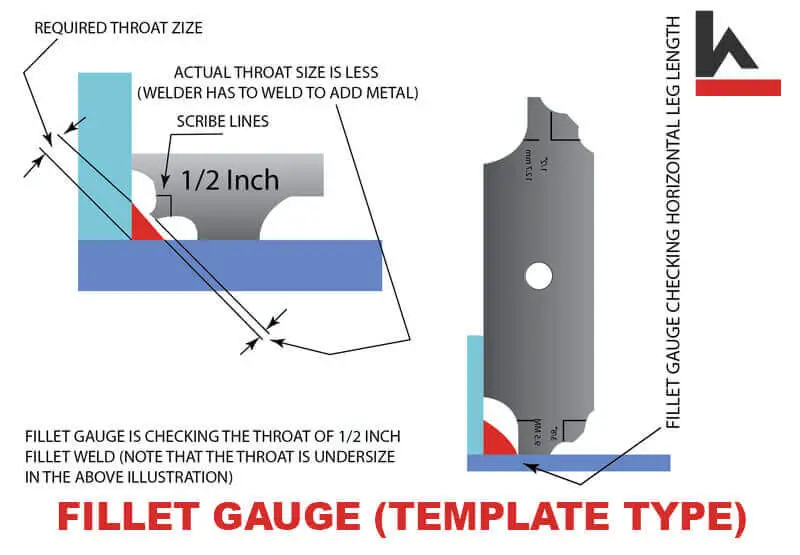

To check the vertical leg length, ensure the orientation of the fillet gauge is correct. And flush the longer side of the fillet gauge with the surface of the horizontal member of the weld. Move the fillet gauge toward the vertical piece till it flushes with it.

The vertical toe should make contact with the gauge. Check whether the leg length is okay or not, the image above “Right side” illustrates this. You can move the fillet gauge over the weld length to check at different points.

To check the horizontal leg length, flip the fillet gauge so that the longer side is flushed with the vertical member and the shorter length with the horizontal member (the horizontal toe should have contact with the fillet gauge).

Checking Throat Thickness

Place the fillet gauge on the horizontal member of the weld to flush with the longer side on it. And the side for checking the throat facing the vertical member of the weld.

Move the fillet gauge towards the vertical member till it strikes its surface. With the fillet gauge flushing with horizontal and vertical members of the weld, you can check the throat to know whether it is okay or not.

Grab one of the fillet welding gauges to measure the throat thickness according to your specified thickness needed. Check if the protrusion in the middle of the gauge makes contact with the weld. If there is space between the weld and the protrusion, the weld is concave, which should not be.

In the example shown in the above illustration “left side”, the throat is insufficient, and the welder needs to do additional welding. The scribed lines on the fillet gauge indicate if the leg lengths are okay or not, and obviously, they are also not okay.

You can check the throat at different locations over the weld length. If the throat is okay, the protruded part of the fillet gauge will touch the weld face (in our illustration above “Left side,” there is a gap).

How to use an Adjustable Fillet Weld Gauge to Measure the size of a Fillet Weld?

There will be a variety of adjustable fillet gauges, and their working principle will be more or less the same. However, if you plan to purchase one, enquire about their range (minimum and maximum leg length and throat).

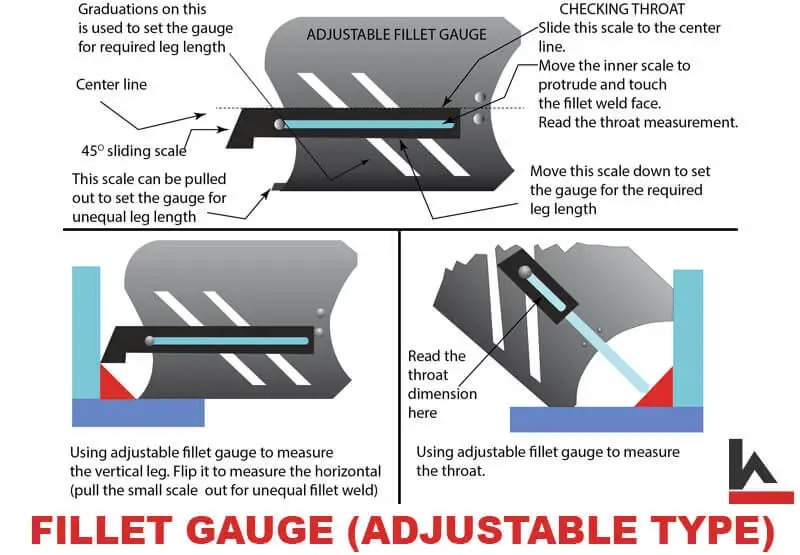

This adjustable fillet gauge has a 45° sliding scale (which slides up and down at a 45° angle), a sliding scale that slides to and from the 45° sliding scale, and a small scale at the bottom that will protrude out for measuring unequal-length fillet weld.

Checking Leg Lengths

Checking the vertical leg length of the fillet: Move the 45° slide down to match it with the required size of the fillet (let us say 1/2ʺ). Then, place the gauge butting against the horizontal and vertical weld members to check the vertical leg length.

If the vertical toe does not touch the 45° sliding scale, the weld is undersized. Which means that it does not conform to the specification. Move the 45° sliding scale up or down to make it touch the toe. Then, view the actual dimension of the leg.

To check the horizontal leg length, flip the gauge accordingly and check/measure the horizontal leg length.

For measuring the unequal leg length, calculate the difference between the two leg dimensions. Then, pull the small scale (at the bottom of the gauge) out to set it to that difference. In this case, the horizontal toe will touch the tip of the small scale instead of the gauge.

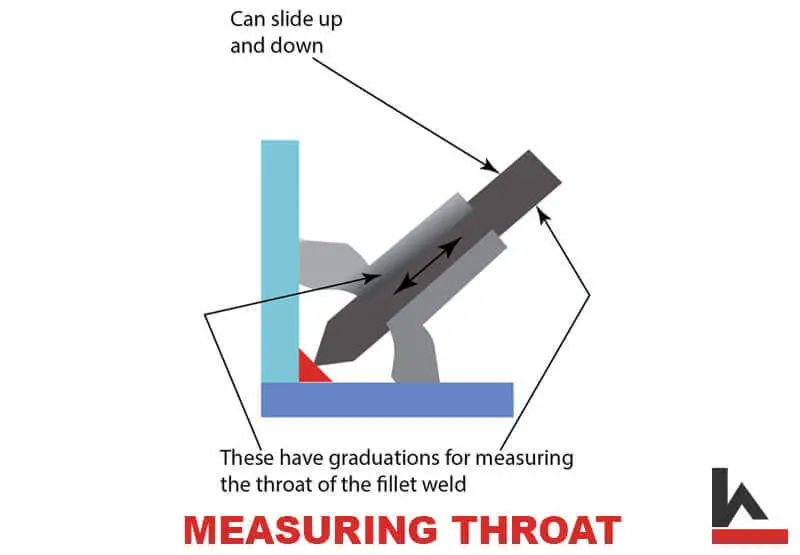

Checking the Fillet Weld Throat Thickness

Position the adjustable fillet gauge flushing with the horizontal and vertical weld members (see the above image). Push the sliding scale (from the 45° scale) toward the weld face till it touches it. View the reading in the gauge to know the actual throat.

Conclusion

Inspection is an important part of fabrication since it helps identify the problems early and avoids wasting time and money. Fillet weld gauges help the inspector check the fillet welds and verify their compliance with the job standards. Even welders can use them to ensure their welding is okay.

I hope that you have gained some understanding about fillet gauges from reading this article.

Reference: