Welding is a process used to combine pieces of metal by melting and fusing them. It requires skill, precision, and the right set of tools to ensure a successful weld. Welding tools are specially designed equipment and accessories that help welders perform their tasks effectively and safely.

From protective gear to measurement tools, welding tools are essential for every welder to have in their arsenal. This article will explore some must-have welding tools that make a welder’s job easier and more efficient.

Why do welders need tools?

For welders, welding tools are far more than mere conveniences – they are essential for various reasons. Here are some key factors to consider:

Safety Enhancement

High temperatures and molten metal are ever-present hazards in welding. This necessitates protective gear, which shields welders from the potential dangers inherent in their work.

Helmets, gloves, safety glasses and welding jackets are some of these tools that block harmful sparks, UV radiation, and debris. They provide comprehensive protection, enabling welders to operate in a secure environment.

Increased Efficiency

Efficiency is another crucial benefit tools bring to the welding process. Welding demands meticulous measurements, exact cuts and right alignment.

Tools like speed squares, tape measures and angle grinders are instrumental in achieving precise angles, measurements and cuts. Welding clamps and vice grips maintain stability of pieces while welding, ensuring an accurate weld. Welding carts and tables facilitate an organized workspace with immediate equipment availability.

Precision Improvement

Tools also contribute significantly to precision in welding. This process is fundamentally about forming durable and lasting bonds between metal pieces. To this end, it’s imperative that surfaces are clean and fit-up between pieces is appropriate.

Tools like wire cutters, metal files, and wire brushes assist in maintaining clean surfaces and proper fit-up. Sheet metal gauges provide information on metal thickness, allowing welders to regulate the welding process better.

Essential Welding Tools for Every Welder

Here is a list of the best welding tools for beginners to learn the trade safely and efficiently:

1. Auto-Darkening Welding Helmet

A welding helmet is an essential protective gear that every welder should have. A welding helmet plays a crucial role in shielding the welder’s face and eyes from heat, flying sparks, and harmful rays emitted during welding.

An auto-darkening lens is the most important feature when choosing a welding helmet. This technology allows the lens to adjust its shade level automatically depending on the welding process, providing optimal protection without changing the lens manually.

The additional benefit of auto-darkening helmets is that they shield your eyes from the glaring lights produced by other welding instruments and the heated metal. You can see without harming your eyes because the glass above your eyes is shaded to only let a specific amount of light through at a time.

For auto-darkening helmets, our top picks are the Lincoln Electric VIKING 3350 Auto Darkening Welding Helmet and the Miller Black Digital Infinity Series Welding Helmet.

2. Welding Gloves

Welding gloves are an essential tool and protective gear for welders. These gloves protect hands from sparks, flames, and intense heat. They comprise multiple layers of strong fabrics, such as leather, and often have insulating material to provide extra protection.

It’s simple to purchase welding gloves anywhere that sells gloves, but they’re necessary for any welding you might undertake. There are two main categories of welding gloves: MIG gloves and TIG gloves.

MIG gloves

These are typically thicker and more durable, offering better resistance to heat and splatter. These have padding on the back of the hand to protect your resting hand while bracing the dominant hand during a weld. They are perfect for heavy-duty welding projects where extra protection is required.

There are a number of MIG welding gloves in the market. But we would recommend the YESWELDER Leather MIG Welding Gloves and the Revco GM1611 MIG Welding Gloves.

TIG gloves

These gloves are lighter and more flexible, providing enhanced dexterity. Dexterity is crucial when performing TIG welding, and these gloves are designed to have a tight fit to facilitate precise movement while holding the rod and torch.

Consider options like the Lincoln Electric Dexterity TIG welding Gloves, which are among the best available in the market. market.

3. Safety Glasses

Safety glasses are designed to shield your eyes from various dangers typically associated with welding. They provide protection against heat, optical radiation, flying debris, and liquid chemical splashes. Safety glasses can be an effective alternative to full-welding helmets When working on projects involving light-duty welding or tasks that don’t generate excessive sparks or weld spatter.

They provide a comfortable fit, allowing for extended periods of wear without causing discomfort. However, it’s important to note that a welding helmet should always be used to ensure maximum protection for more intensive welding jobs, such as those producing significant sparks and weld spatter.

Our top choice for welding safety glasses is the YESWELDER True Color Auto Darkening Welding Goggles.

4. Welding Jacket

A welding jacket is an essential protective gear that protects against sparks, spatter, and intense heat during welding operations. The primary function of a welding jacket is to shield the welder’s body from flying sparks and molten metal spatter that can cause severe burns and injuries.

It acts as a physical barrier, preventing these hazards from directly contacting the skin. In addition, the jacket’s flame-resistant materials help to minimize the risk of the fabric catching fire when exposed to extreme heat. Some jackets also feature pockets for conveniently storing small tools or accessories.

Our top choice for heavy duty welding jacket is the Lincoln Electric Heavy-Duty Welding Jacket. For welding in summer and hot conditions, a lightweight jacket is best. For a lightweight jacket, we recommend Lincoln Electric KH808L Welding Jacket.

5. Welding Boots

Regarding personal protective equipment for welders, one crucial item often overlooked is welding boots. These specialized boots are designed to provide foot protection against the unique hazards encountered in welding environments.

Welding boots are vital in safeguarding the welder’s feet from various dangers, including molten metal splashes and heavy objects that could cause severe injuries. The intense heat generated during welding can cause the metal to splatter and create molten droplets that can easily burn through regular footwear.

Knowing this, you should protect your feet from the hot metal and heavy equipment you will work with while welding. The Timberland PRO Men’s MetGuard Boot is a great choice for welders looking for durable and comfortable welding boots. And the DRKA Water Resistant Steel Toe Welding Boot provides great protection from electrical hazard.

6. Ear Protection

Welding processes also generate high noise levels, often exceeding the recommended exposure limits. Prolonged exposure to these high noise levels can lead to permanent hearing damage. By wearing proper ear protection, welders can protect their ears from the loud noises associated with welding.

Various types of ear protection are available for welders, including earmuffs and earplugs. Earmuffs like the ProCase Noise Reduction Ear Muffs provide a protective barrier around the ear. While earplugs like the Loop Quiet Ear Plugs are inserted into the ear canal. Both options offer effective noise reduction, but choosing a type that is comfortable and fits properly is important.

7. Welding Respirator

Exposure to welding fumes and gases can have serious health effects, such as lung damage and respiratory irritation. This is why wearing a welding respirator is crucial for welders.

Different welding respirators are available, including disposable and reusable respirators. Disposable respirators like the AccuMed BNX N95 Mask are ideal for short-term use and are lightweight and inexpensive. Reusable respirators are more durable and can be fitted with replaceable filters for long-term use. A great reusable respirator is the 3M Half Facepiece Reusable Respirator.

8. Welding Knee Pads

Welding knee pads are designed to safeguard the knees from various hazards that can be present on the ground during welding. As welders work, shrapnel, debris, and jagged pieces can be scattered around the workplace. Without proper protection, these objects can cause severe injuries and discomfort.

Not only do welding knee pads protect the knees, but they also provide added comfort. The padding and contoured design help distribute weight evenly, reducing knee pressure and improving overall productivity. The Thunderbolt Knee Pads are a great option for welders seeking protection for their knees.

9. Fire Extinguisher

In case of an accidental fire, having a fire extinguisher within arm’s reach can significantly prevent the fire from spreading and causing extensive damage.

These are fire extinguishers specifically designed for welding applications, ensuring they can withstand the unique challenges and hazards associated with welding. We highly recommend the use of Kiddle Fire Extinguisher.

10. Welding Machine

A welding machine is an essential tool for welders, as it allows them to combine pieces of metal to create a strong and durable bond. Whether working on a construction site or building metal sculptures in your garage, having the right welding machine is crucial.

The first step in choosing a welding machine is determining the kind of welding jobs you’ll do. Different welding processes, such as stick welding, MIG welding, and TIG welding, each require a specific type of machine.

In many cases, employers will supply welding machines for workers to use on the job. However, you’ll need to purchase your machine if you’re doing welding jobs at home or for clients.

For TIG welding, we recommend the Lincoln Electric Square Wave TIG 200 TIG Welder. And for MIG welding, we highly recommend the Hobart IronMan 240. But if you would love to use one machine for a variety of welding processes, we recommend the Multi-process Hobart 500578 Multi-Handler 200.

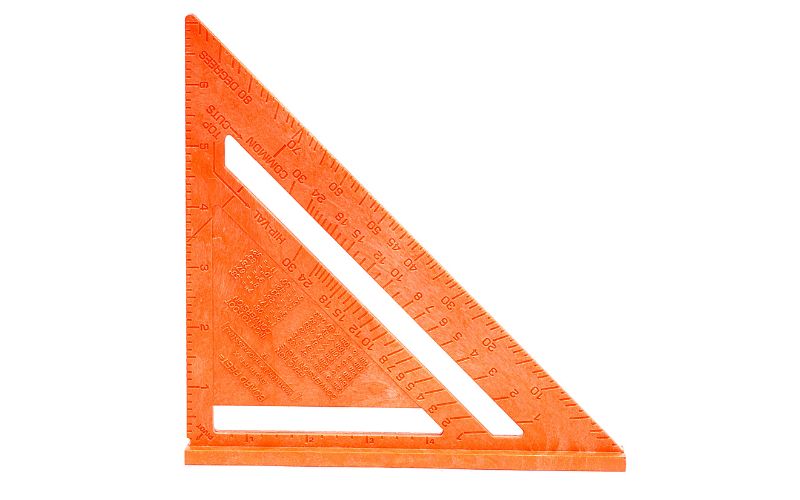

11. Speed Square

A speed square is an angular measuring device shaped like a right triangle, allowing for multiple forms of measuring at different angles. Using your speed square, you may measure any piece perpendicular to another for a 90-degree cut or at any other angle.

One of the main features of the Speed Square is its ability to mark 45 and 90-degree angles with precision. A speed square like the Swanson Co. Speed Square is especially useful when welding joints or making cuts that require precise angles.

In addition to marking angles, the Speed Square includes a protractor, allowing users to accurately measure angles between 0 and 90 degrees. Another notable feature of the Speed Square is its ability to make square cuts. By aligning the tool against the edge of the material, welders can create clean and precise straight cuts, ensuring the integrity of their work.

12. Welding Magnets

Welding magnets are a versatile tool every welder should have in their arsenal. One of the main benefits of welding magnets is their ability to hold metal pieces in place at various angles. This is particularly useful when working on projects that require angle welding, such as creating corners or joints.

Another advantage of welding magnets is their ability to hold sheet metal firmly during welding. Sheet metal can be thin and flimsy, making it challenging to keep in position while welding. Welding magnets eliminate this problem by providing a strong magnetic grip on the sheet metal, ensuring it stays in place throughout the welding process.

In short, they allow pieces of sheet metal to be welded in ways that clamps would not allow. Welding magnets come in various sizes to accommodate different project sizes and requirements. A good example is the YESWELDER Welding Magnet.

13. Welding Clamps

One of the must-have tools for welders is welding clamps. These clamps play a crucial role in holding pieces of metal together during welding, ensuring that they stay in the desired position for accurate welding.

Welding clamps work with locking clamps to hold large pieces of metal together securely. By using both clamps, welders can create a stable and secure workpiece ready for welding. The locking clamps firmly hold the metal pieces in place, while the welding clamps provide additional support and ensure that the pieces do not move or shift during the welding process. We highly recommend the SANDOR Welding Clamps.

14. Chipping Hammer

The purpose of a chipping hammer is to chip away the excess material that forms during the welding process. This includes removing the slag, the residue left behind after welding, and any spatter that may have landed on the metal.

By removing these unwanted materials, welders can ensure that their finished projects have clean and smooth surfaces. A hammer like the ESTWING Chipping Hammer is very effective for this.

15. C Clamps

C clamps, or G clamps, are essential tools every welder should have in their toolbox. These versatile clamps are commonly used in welding projects to secure the workpiece to a table or bench.

One of the main reasons why using C clamps is important in welding is to prevent warping. When heat is applied to metal during welding, it can cause the metal to expand and contract. This can lead to distortion and warping of the workpiece. By securely clamping the piece to a table with C clamps, you can minimize the movement and maintain the desired shape and alignment.

C clamps also allow for greater pressure than pinch clamps or even some welding clamps, allowing for a much more solid hold on whatever you need to clamp.

Having multiple C clamps of different sizes is highly beneficial in the workshop. Different welding projects require different clamping pressures and jaw sizes. You can easily choose the appropriate clamp for each task by having a variety of sizes.

16. Metal Brush

Metal brushes are crucial in welding processes that create slags, such as stick welding or flux core arc welding. Slag is a byproduct of the welding process and can form a crust over the weld, making it necessary to remove it to reveal the true weld underneath. Metal brushes are perfect for this task as they have stiff bristles that scrub the slag without damaging the weld.

Furthermore, metal brushes are also useful for removing charring or burnt areas around the weld. The intense heat can sometimes cause charring on the surrounding metal when welding. You can easily remove these imperfections using this YiwerDer Metal Brush and achieve a smooth and professional finish.

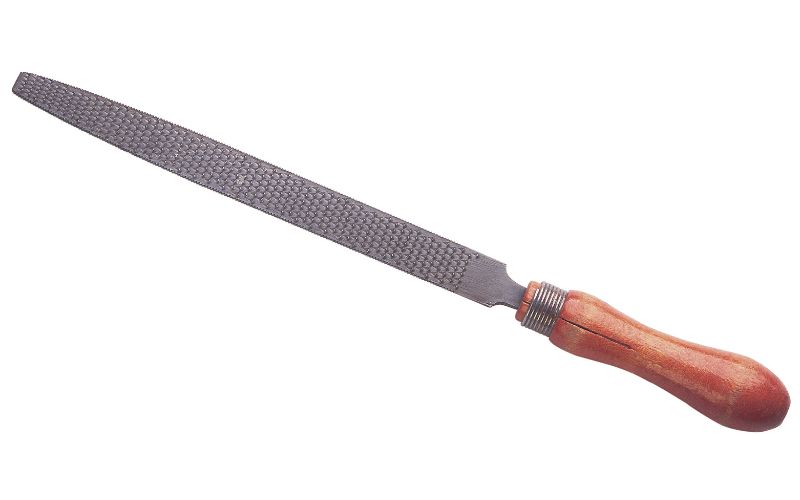

17. Metal File

A metal file helps in removing rough edges and burrs from metal cuts. Its primary purpose is to smooth and refine the edges of metal pieces, ensuring the quality and precision of the weld.

A set of metal files typically includes a variety of file sizes and shapes, offering versatility and flexibility. With six different files, welders can choose the file that best suits the task. The KALIM Metal File made of high carbon steel is a suitable choice for welders.

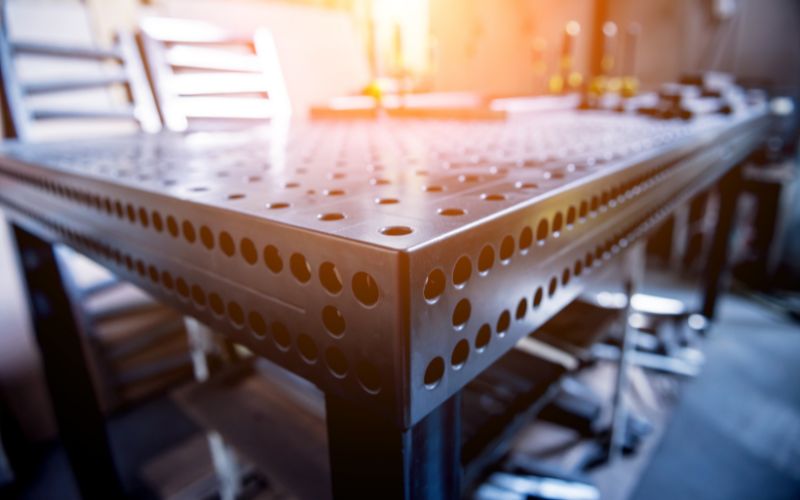

18. Welding Table

A welding table is an essential tool for welders. It provides a stable surface for precise work, ensures comfortable working height, facilitates easy transportation, and organizes welding equipment effectively.

A portable welding table offers the added benefit of easy transportation. Instead of carrying heavy equipment and materials by hand, a portable welding table allows welders to move everything they need from one location to another conveniently. We highly recommend the VEVOR Steel Welding Table for its sturdiness and durability.

19. Sheet Metal Gauge

A sheet metal gauge is another indispensable tool in welding. It helps in determining the exact thickness of the sheet metal, which is particularly important in achieving a precise and smooth weld. Having an accurate sheet metal gauge means you have more control over your welding application, ensuring a top-notch finish every time.

Our recommendation for a top-quality sheet metal gauge is the YESWELDER Round Dual Sided Metal Sheet Gauge & Metal Sheet Thickness Gauge. This dual-sided gauge is designed for seamless use with both sheet metal and wire, making it a versatile addition to your welding tool kit.

20. Marking Tools

There are several types of marking tools that welders commonly use. Soapstone is popular because it can make clear and visible marks on metal surfaces. With its smooth texture and high visibility, soapstone is ideal for marking measurements, guidelines, and cutting lines.

Another commonly used marking tool is a scribe. Scribes are versatile tools that can mark metal surfaces with precision. They have sharp tips that can scratch through paint or mill scale, making them perfect for marking metal before welding. Permanent markers are also handy marking tools that are widely used in welding. They allow for easy and quick marking on a variety of metal surfaces.

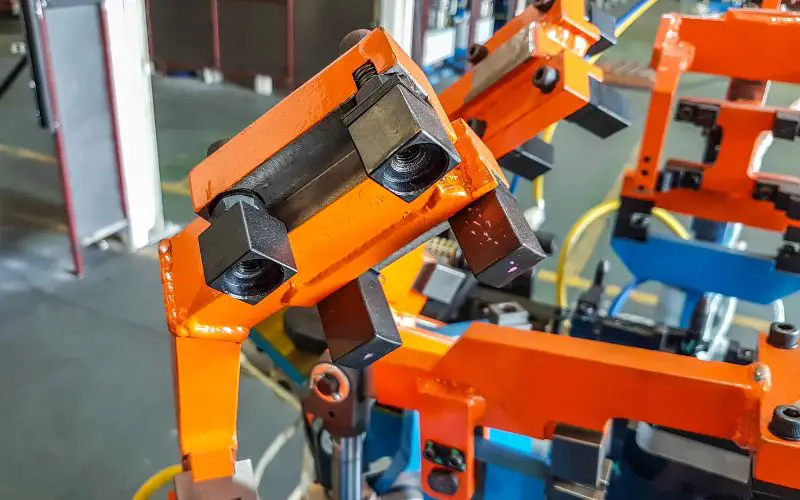

21. Welding Framing Jig

A welding framing jig is not on the same level of necessity as many other items on this list, but it is still a nice piece of equipment. A welding framing jig is vital for welders who need to create square frames with precision and ease. Its purpose is to securely hold two end pieces in place, allowing for accurate alignment and tack welds.

While a welding framing jig is a popular choice, an alternative option is to use C clamps. However, C clamps may not offer the same stability and accuracy as a dedicated jig, especially when working with larger or heavier metal pieces. Therefore, a welding framing jig is recommended for welders who prioritize efficiency, accuracy, and the creation of square frames.

22. Angle Grinder

An angle grinder is a versatile power tool that is commonly used in the field of welding. It has a spinning abrasive disc or wheel that can be adjusted to different angles, hence the name “angle grinder.” This angular grinder is primarily used for cutting, grinding, and polishing metal.

You will want to clean the base metal to avoid defects like porosity and cracking. While this can be done with a wire brush, an angle grinder can save time.

With its compact design and high-speed rotating disc, an angle grinder can make quick work of tasks such as trimming metal joints, removing rust or paint, and shaping pieces. It allows welders to achieve precise cuts, smooth finishes, and accurate shaping, making it an essential tool in any welding workshop.

Angle grinders are available in various sizes and power levels and can be powered by electricity, compressed air, or batteries, depending on the model. A great choice of an angle grinder is the DEWALT Angle Grinder.

23. Portable Band Saw

One of the main benefits of a Portable Band Saw is its ability to produce clean and accurate cuts. Unlike other cutting tools, the band saw uses a continuous loop of the teethed blade that moves vertically. This ensures smooth and precise cuts, eliminating the need for extensive grinding or filing after the cut is made.

The VEVOR Portable Band Saw is a great choice as it can be used on a variety of materials.

24. MIG Pliers

MIG pliers are designed to perform several functions, such as wire cutting, removing and cleaning the contact tip, nozzle cleaning and installation, among others. These pliers are mainly utilized to maintain MIG guns and ensure the wire feeds through the gun.

MIG welding pliers are quite versatile and can be used for various tasks. For example, MIG pliers can be used for cutting, bending, and removing steel wire. They can also be used to crimp and strip wires, making them useful for other tasks in the welding workshop.

Additionally, MIG pliers have circular clamps ideal for taking nozzles out of MIG guns. Cleaning the inside of the nozzle from the spatter is easier with the tips of the pliers. It will be necessary to loosen often and tighten the contact tip as it wears out. The YESWELDER MIG Pliers are a durable choice as it is made of carbon steel and anti-rust.

25. MIG Welding Nozzle Gel

Spatters, the small droplets of molten metal that can splatter during welding, can cause various issues, such as wire feeding problems and inconsistent gas flow. By applying the MIG welding nozzle gel to the welding nozzle, welders can significantly reduce the amount of spatter that sticks, thus minimizing these potential problems.

The gel is designed for MIG welding and can benefit flux core welding. However, it’s important to note that even with the gel, occasional cleaning of the welding nozzle may still be necessary, especially during prolonged welding sessions or when working with particularly dirty or oxidized metals.

The COOTER Snot Tip Dip is great for preventing weld spatter and is also compatible for a variety of welding processes and positions.

26. Welding/Shielding Gas

Welding/shielding gas is crucial, ensuring clean and strong welds. It acts as a protective barrier, shielding the weld pool from atmospheric contaminants like oxygen and nitrogen, preventing oxidation and reducing the risk of defects.

Different types of shielding gases are used for various metals. It is important to check the gas requirements for specific welding processes and consult with experts to ensure the right shielding gas is selected for each project.

27. Oxy-Acetylene Setup

The versatility of the oxy-acetylene setup is one of its greatest advantages. It allows for precise welding, cutting, and bending of different types of metal, making it suitable for a wide range of projects. Whether you are working on automotive repairs, metal fabrication, or artistic creations, the oxy-acetylene setup provides heat intensity and control to achieve desired results.

We recommend the RX WELD Oxy Acetylene Kit. It is imperative to follow proper safety precautions such as keeping the setup away from flammable substances, wearing suitable protective gear, and ensuring proper ventilation in the workspace.

Conclusion

Welding is a skilled trade that requires precision, accuracy, and proper training. However, having the right tools is essential for achieving optimal results. Every welder needs several must-have tools, from the welding machine to safety gear in their workshop.

Investing in these tools ensures that you work efficiently and guarantees job satisfaction and, ultimately, a successful welding career. Now that you know what welding tools and accessories you need to weld safely, get the ones you need and get to work!