Laser beam welding (LBW) is a thermal process to join metals by bonding them using a laser beam; the process is widely known as Laser welding.

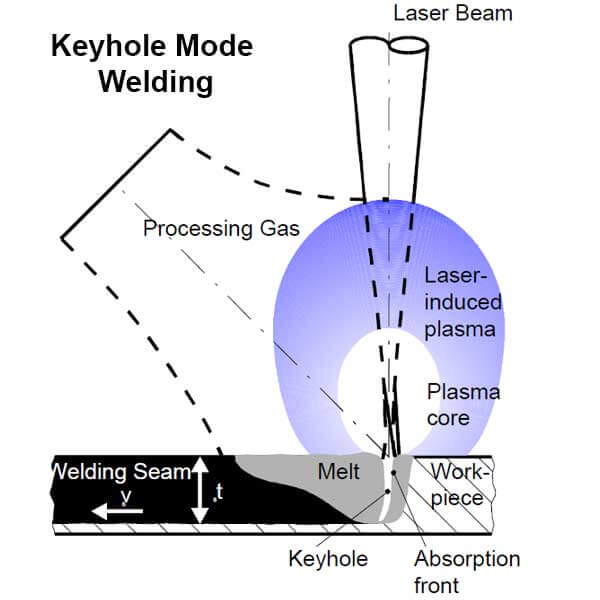

Laser welding consists of an extremely high power density laser beam; the beam is powerful enough when it is focused on the metal to vaporize a hole through the metal and the keyhole thus formed. As the beam passes through the joint, the metal starts to melt, creating melt pool flows into the rear of the keyhole, the molten metal solidifies and form a weld.

What is a LASER?

LASER means the physical effect of light amplification by stimulated emission of radiation. The emission bases on an interaction between light and matter on which the matter emits the enforced radiation. In laser, light amplification takes place through stimulated emission of electromagnetic radiation.

LASER is an acronym for Light Amplification by Stimulated Emission of Radiation.

What are the Properties of Laser?

The laser beam’s properties significantly affect the quality of laser welding and other laser applications. These properties include beam divergence, monochromaticity, beam coherence, brightness, and beam characteristics, including beam mode, beam stability, and beam polarization.

A. Laser Beam Divergence

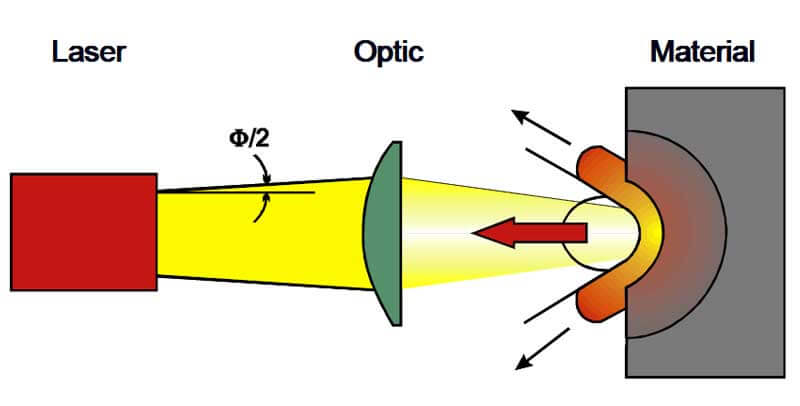

Beam divergence means the laser’s characteristic to increase the laser beam cross-sectional area with the increase in distance from the source. Laser beam cross-section remains almost constant throughout the path of travel. Hence, laser divergence is very low, facilitating the beam to be focused to a small radius generating a large amount of energy at that point. For laser welding applications low beam divergence is essential.

B. Laser Beam Monochromaticity

A monochromatic beam means a beam that contains a single wavelength, a laser beam includes a single wavelength only, and therefore it is monochromatic. Monochromatic is essential in laser welding application as it determines the focus degree of the laser beam. A monochromatic beam can focus sharply at a certain point, as the beam radius at the point of focus can be equivalent to the beam wavelength.

C. Laser Beam Coherence

Beam coherence means the fixed phase relationship between two points of the same wave or two different waves of the same beam. The laser beam is coherent, which means the laser beam wavelengths are in a similar phase in space and time.

D. Laser Beam Brightness

Brightness is one of the laser source’s essential properties, laser source brightness at a point determined as the power emitted per unit surface area per unit solid angle.

E. Laser Beam Characteristics

The following laser beam characteristics have a significant effect on the laser welding process:

- Beam Power Mode: The beam power mode density defines the shape of the weld bead; higher power density results in a higher depth to-width ratio and vice versa.

- Beam Stability: Beam stability is the repeatability of the beam characteristics. Beam stability is essential to maintain weld quality.

- Beam Polarization: Polarization provides the direction identification of laser beam; beam direction is always at right angles to the propagation direction on which the electric field is vibrating. Weldment material and welding condition define the influence of beam polarization on the welding process.

What are the Sources of Laser?

Laser sources differ from the wavelength and the laser radiation intensity; each laser type has different characteristics that depend on the active medium used for laser action.

The common sources of lasers in industrial applications are:

- Solid-state Laser (for example, ruby, Nd- YAG, Nd- Glass)

- Gas laser (CO2)

- Semiconductor laser or Diode Laser

1. Solid-State Laser

Solid-state lasers typically use a crystal or insulating material as an active medium, for example, ruby, glass, or yttrium aluminum garnet (YAG laser). The active medium is an either dopant or acts as an impurity inside what is called the host material. The active medium present in the host material participates in laser action. However, the host material itself has no direct effect on the process.

Solid-state lasers are either continuous wave or pulsed beam types. The industrial solid-state lasers have a wave power of 10 W till 5 kW, and the Laser emits in light with a wavelength of 1,064 μm considerably shorter than that of the C02 Laser.

The continuous-wave Laser has higher process speeds than the pulsed systems at the same power. The pulsed lasers can reach a pulse power up to 20 kW, which produces a higher welding depth. It is possible to weld steel, aluminum, copper, and many other metals, specifically tricky materials such as tantalum, titanium, zirconium, Inconel.

Many applications of Solid-state lasers are welding, cutting, drilling, and marking. The typical examples of solid-state lasers incorporate the ruby, Nd: YAG (Neodymium: Yttrium Aluminum Garnet), and Nd: Glass laser.

A new type of Solid-State Laser has been developed, called fiber laser. The generating of laser beam occurs by directly pumping diode light into a fiber optic generating the laser beam. Fiber laser technology provides excellent beam quality with more simple yet highly capable laser machines.

2. Gas Laser (CO2)

The general assembly of a CO2-Laser is a resonator between both mirrors filled with a mixture of gas, CO2, N2, and He. The process of energy input occurs through an electric discharge through the gas. Therefore, CO2 lasers can produce a high power output, much higher powers than Nd: YAG lasers.

As CO2 lasers have a higher power, the process is used widely in welding applications, where welding is performed more quickly and for thick plates; besides, CO2 lasers are used for cutting applications and surface treatment.

During welding, a shielding gas usually is helium or an argon/helium mixture used to protect the lens and the weld. Helium is preferred due to its high ionization energy.

C02 lasers are either continuous wave or pulsed beam types with output frequencies ranging from ultraviolet to infrared, CO2-lasers emit light with a wavelength of 10.6μm, and they have an efficiency of 10 %. The shorter wavelength enables the light to be carried by fiber optics and focused with ordinary lenses.

3. Semiconductor Laser or Diode Laser

Semiconductor lasers provide cheaper industrial solutions and more compatibility in size. However, the beam quality for semiconductor lasers is not high than the beam quality of solid-state lasers or CO2– lasers. It is difficult to concentrate the beam sufficiently with semiconductor lasers.

How does laser welding work?

The laser welding process occurs by focusing the laser beam using lens or mirrors, the beam strikes the surface, and accordingly, a portion of the light energy will reflect. The material will absorb the rest of the light energy.

The material melts or even vaporizes; the vaporized metal generates a plasma, which improves energy absorption further and the efficiency of the process. The absorption depends on the material type, temperature, wavelength, and intensity of the laser beam. The beam focusing at a small point provides a concentrated heat source, which produces narrow and highly penetrated welds.

To prevent air from reacting with the molten metal and protect the weld, shielding gas is used. Shielding gas as well protects the lens from spatter and vapor.

The metal solidifies at a fast rate as soon as the laser beam is moved; the rapid solidification rate produces a small heat-affected zone and minimizes metal distortion. The welding penetration is usually controlled by laser output power. The welding process using the laser beam does not require filler material except for hybrid welding.

The welding process starts with clamping the workpiece properly on the laser welding machine bed; the welding machine parameters are set as per the weld joint design and workpiece geometry to supply the necessary power. The weldment details feed in the machine, and the joint edge (start point) is defined using a laser scanner within the machine; the process then starts!

What are the Types of Laser Welding?

The two types of laser welding are:

- Heat Conduction Welding.

- Deep Penetration Welding (Keyhole).

1. Heat Conduction Welding

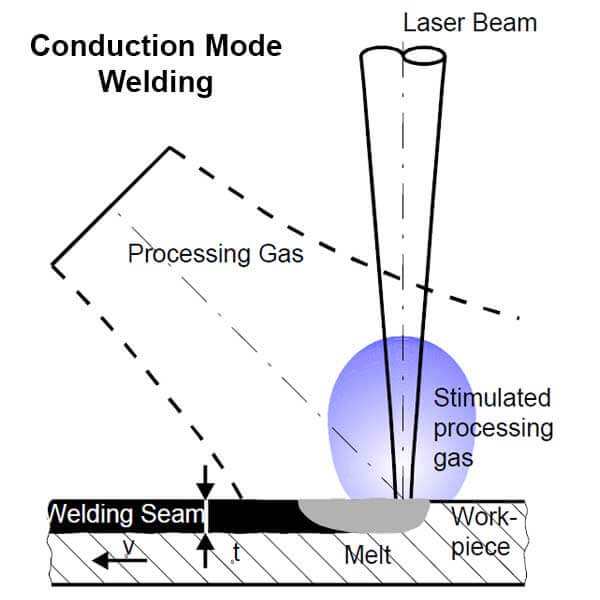

Heat conduction welding uses low power density, which is less than 106 W/cm2, heating the workpiece to a temperature above the melting temperature without vaporizing.

Conduction welding has a low welding depth and small aspect ratio compared to keyhole welding. This welding process has low coupling efficiency; however, the produced weld bead is very smooth.

The heat conduction welding application is the welding of thin workpieces like foils, wires, thin tubes, etc.

2. Deep Penetration Welding (keyhole)

Keyhole welding uses a high power density of 105 – 106 W/cm2, heating the workpiece above the evaporating temperature and creating a keyhole due to the flowing metal vapor’s ablation pressure.

Keyhole welding has a high welding depth and a small aspect ratio.

Laser-Hybrid Welding

Laser-hybrid welding is the welding process that combines laser beam welding with another arc welding. Laser welding usually combines with either TIG, MIG, or plasma welding. Laser combination with MIG welding is the most common industrial laser-hybrid welding. Laser and MIG welding combination enhances laser welding capability to weld thicker plates.

Laser Welding Joint Configuration

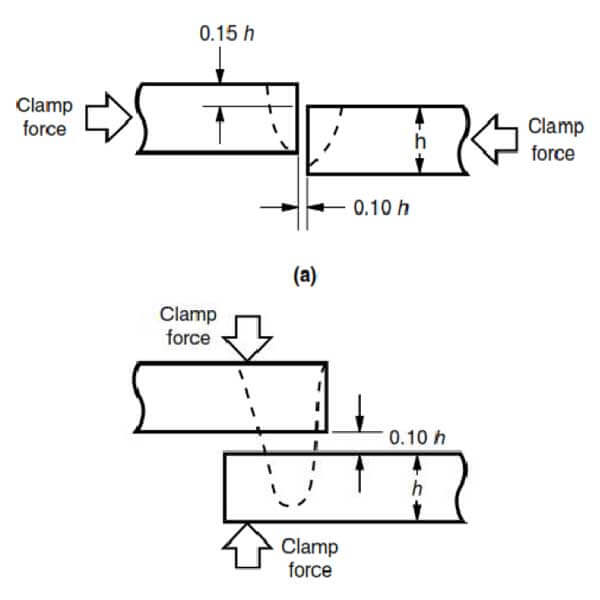

Lap joint configuration is common in laser welding. Butt joint configuration is more challenging; the laser beam passes away through the gap and results in improper joining between the joints.

In order to avoid laser beam passing through the butt joint gap, the gap should not exceed 10% for metal sheets thickness of 0.5~3.0mm and 5% for a metal sheet of 3.0mm and above.

Lap joints are the more appropriate choice for weld joints whenever the workpiece is relatively thin.

Advantages and Disadvantages of Laser Welding

Advantage

- Laser welding is a high speed and high productivity welding process; laser welding is approximately twice faster than plasma welding and eight times faster than TIG welding.

- Laser welding produces a narrow heat-affected zone and low distortion.

- Laser welding is a clean and quiet process.

- Laser welding provides excellent dimensional tolerances.

- Laser welding is the ideal choice for welding materials that can accept only a low heat input.

- Laser welding usually uses for welding materials that are difficult to weld and dissimilar materials.

- Laser welding is not affected by the magnetic field; hence, the process eliminates welding defects associated with the magnetic field presence, such as Arc Blow.

- Laser welding usually use for welding complex parts, and parts require high precision; therefore, laser welding is widely available in the automotive and aerospace industries.

Disadvantages

- Laser welding produces a low width depth ratio welds on which may result in thermal cracking.

- The rapid rate of cooling can locally harden hardened steel.

- Equipment investment cost is relatively high.

- Laser welding is not suitable for welding thick metals.

- Laser welding machines consume high energy power.

- Laser welding machines have associated health hazards that need to consider and eliminate.

Related Article: Laser Beam Machining And Surface Treatment

How to Select and Purchase a Laser Welding Machine

1. Select Laser Type

Based on the material’s thickness, select one of two types of lasers: a pulsed or a continuous.

- Pulsed Laser: suitable for light and thin workpieces, a pulsed Laser prevents deformation.

- Continuous Laser: suitable for thick workpieces, it may cause damage or deformation for thin workpieces.

2. Select Laser Beam Source

Based on the energy efficiency and application, select one of the common industrial laser beam source: CO2 laser, Nd: YAG laser, and fiber laser.

- CO2 Laser: CO2 Laser can penetrate thick sheets with high speed, CO2 can penetrate thicker plates than fiber laser, and therefore, it is widely used. CO2 Laser can be used with the thick as well thin material, which gives it great flexibility.

- Nd: YAG laser: Nd: YAG laser is configured with pulsed mode; the process effectively controls the power, duration, and shape of the laser pulses.

- Fiber laser: fiber laser is capable of penetrating thick sheets with high speed. The fiber laser machine is easier to use and to maintain.

The energy efficiency of each laser source is as follow:

- CO2 Laser 7~10%

- Nd: YAG laser 3~4%

- Fiber laser 25~30%

3. Select Machine Configuration

Based on the production scale, select one of three types of configurations: Manual, semi-automatic, or automatic.

- Manual welding machines: Compact welding machines; the process is controlled by an operator. The machine is suitable for small-scale production.

- Semi-automatic laser welding machines: Larger than manual welding machines, the machine is suitable for medium and large-scale production.

- Automatic laser welding machines: The largest machines compared to manual and semi-automatic machines. Automatic laser welding machines are robotized and automatically controlled. The machine is suitable for large-scale production.

References:

- AWS: Welding Handbook

- Direct Industry

- The Welding Engineer´s Current Knowledge Book