Welders new to MIG and TIG have difficulty determining how much gas they need in their welding gas cylinder since they must create precise calculations for how much gas they will demand while welding. Nobody likes to go through the difficulty of filling up their gas tank every other day.

On the other hand, transporting and storing these massive tanks could be difficult. Because of this, it is helpful for new welders to know how long different sizes of gas tanks last. This article will take you through welding gas tank sizes and specifications, types of gases, and how to calculate the welding duration for every cylinder size.

Welding Gas Tank Sizes & Specifications

Argon is one of the most important gases in this situation, preferably the most important gas overall. Because different types of tanks need different amounts of argon and other gases, you will need to research before starting your project to figure out which tanks to use.

The problem is that the sizes of the welding gas cylinder that manufacturers make are very different. Unless, of course, users count the bottles under a lot of pressure. The makers do this on purpose so that customers can find their tanks quickly and easily, and they sell tanks that look like this.

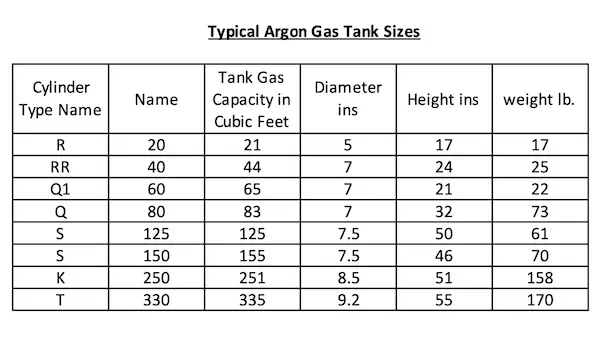

Despite this, they also make tanks the same size as those made by other companies. Here is a list of the most common bottle and tank sizes for argon, along with a letter or number that lets you know what size it is. These are between 21 and 335 cubic feet and include the following:

| Tank Mark | Tank Size |

| R or 20 | 21 cubic feet |

| RR or 40 | 44 cubic feet |

| Q1 or 60 | 65 cubic feet |

| Q or 80 | 83 cubic feet |

| S or 125 | 125 cubic feet |

| S or 150 | 155 cubic feet |

| K or 250 | 251 cubic feet |

| T or 330 | 335 cubic feet |

There are two different tanks to choose from in the S size. It’s important to get accurate measurements of the inside of the tank before making you buy a tank.

Different Tank Sizes

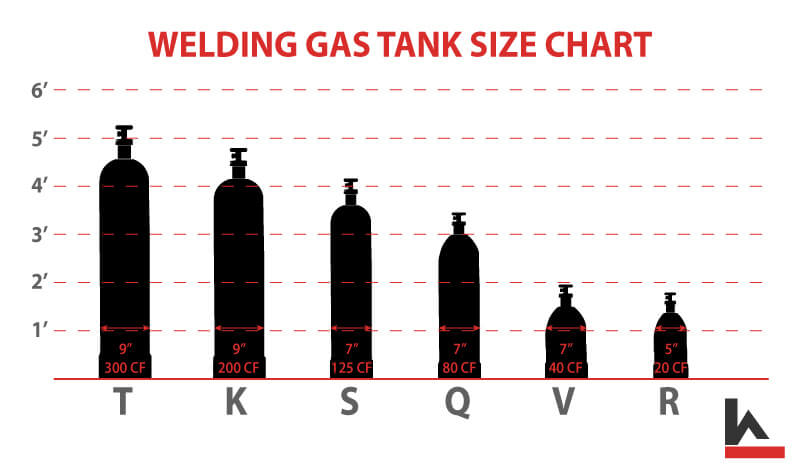

The following chart illustrates the relative cubic foot (“CF”) capacity of different tank sizes as a function of tank height and diameter. This chart may be used to establish whether or not users have space for the gas cylinder you are considering purchasing.

The capacity of the tanks is shown in the figure. Utilize this chart as a guideline. Flexibility in dimensions is available.

The 125cf gas cylinder is popular among professional and amateur welders for various reasons, including its size and volume. It is not as compact as industrial-scale giant tanks, but it can contain twice as much gasoline for the same price as smaller tanks, making it a great offer.

Argon Gas Cylinder Specification

- Several cylinder designations are included in the first column of this table. The second column lists other names for this size of the tank.

- The number of cubic feet of argon gas stored in a given tank is listed in the third column.

- The dimensions of each tank are shown in columns 4 and 5. In the table above.

- The total estimated weight of each tank size is shown in the last column.

- The following metrics are all approximations or mean values.

- However, this chart will serve as a useful resource for locating the most common sizes of welding gas cylinders. And a ballpark figure for how much Argon gas a cylinder of that size should contain.

Best Gases for MIG Welding

Carbon dioxide and argon are the ideal gases to use for MIG welds. The finest quality welds may be accomplished by combining 75% argon and 25% CO2 in a gas combination.

CO2 or Carbon Dioxide

Carbon dioxide (CO2) is a well-liked option for MIG welders due to its characteristics as an affordable semi-inert gas. It is the option with the lowest possible cost. It provides deep metal penetration and the possibility of performing miracles without extra inert gases.

However, the fact that CO2 has sharper arcs means it produces more spatters than other substances. Because of this, the area surrounding the weld zone will need to be cleaned up when the welding process is complete. However, its resistance is much lower than that of inert gases, even though it does not react to the chemical change.

Argon

Utilizing Argon for MIG welding will provide the highest quality welds possible. Argon generates the finest welds for welding aluminum, magnesium, and titanium. However, this is the optimal gas if you only work with aluminum. Typically, MIG and TIG welders use this gas.

This gas is so inert that it will not react with anything, even under the most extreme conditions, and its adaptability makes it helpful in many situations. It is also employed as a purging and shielding gas in the welding industry.

However, it is more expensive than CO2. Thus most individuals use a mix of the two. Despite maintaining a constant arc, argon does not go very far.

Argon and Carbon Dioxide mixture

Argon and CO2 are often combined to provide the welding gas combination used in MIG welding. The most common ratio is 75% argon and 25% CO2. And this is because this mix of gases can be used for a wide range of welding processes and is, therefore, often used. Welding can be done cleanly and with little spatter when there is a lot of argon.

Users need to ensure that the area they are working in has enough ventilation since these gases can potentially reduce the amount of oxygen in the air. When used as a shielding gas for welding stainless steel and carbon steel, the results produced by this combination are superior.

Welding duration and flow rate calculation for a gas tank

When employing MIG or TIG arc welding, there is a simple formula for determining the lifespan of the welding tanks: Following is the formula for estimating gas welding time in hours:

Weld time (hours) = Cylinder volume (CF) Divided by Flow Rate (CFH).

For clarity, assume that you are dealing with inert tungsten gas and want a flow rate of around 20 cubic feet per hour from an 80 cubic-foot argon tank. Generally, welding will require around four hours. Although the formula is not exact, the margin of error is so minimal that it is often used as a rule of thumb in the welding industry. Depending on the size of the gas bottles and the flow rate, the table below will offer an estimate of the duration of the welding process.

| Tank Volume / Size | 10 CFH | 15 CFH | 20 CFH | 25 CFH | 30 CFH | 35 CFH | 40 CFH |

| 40 CF | 4 h | 2.6 h | 2 h | 1.6 h | 1.3 h | 1.15 h | 1 h |

| 60 CF | 6 h | 4 h | 3 h | 2.4 h | 2 h | 1.7 h | 1.5 h |

| 80 CF | 8 h | 5.3 h | 4 h | 3.2 h | 2.6 h | 2.3 h | 2 h |

| 125 CF | 12.5 h | 8.3 h | 6.2 h | 5 h | 4.2 h | 3.6 h | 3.1 h |

The projected times are just approximations. Expect somewhat different outcomes in the actual world but results consistent with the preceding table.

How long does the gas last in the welding gas cylinder?

The gas flow varied from 10 to 40 cubic feet per hour, depending on the task. The formula gas welding time (hours)=[Cylinder Capacity (CF) / Flow Rate (CFH)] is often used by welders.

Temperature variations and beginning and stopping may cause these calculations to be inaccurate. Therefore, the outcome may not be the most exact. This effect will be amplified if your cylinders include pre/post-flow adjustments.

Since temperature variations directly influence your flow rate, you should check the regulator and make necessary adjustments. When you are through utilizing gas for the day, make sure to reset the regulator to zero.

How do we know the amount of gas left in the welding gas cylinder?

A pressure gauge on the regulator of Argon and Argon+CO2 mixed gas cylinders may be used to determine how much gas remains in the tank.

In contrast, the pressure of a pure CO2 cylinder rapidly decreases as it nears its end, making its pressure gauge less accurate.

Finding the Right Size of Welding Gas Cylinder

In the first place, the greatest possible cylinder size is 125 cubic feet. In addition, its weight would range between sixty and eighty pounds. Here are some considerations to ponder while picking the ideal cylinder for your requirements:

- A medium-sized cylinder is ideal if it must be transported or shipped often to the work site.

- A business owner will want a bigger cylinder than a hobbyist since they use their equipment more often.

- Typically, lesser sizes are refilled more frequently than bigger ones.

- When working with these gases, a well-ventilated space is essential.

- Additionally, you must return the gas cylinders if you have moved. Because certain vendors will only refill cylinders from a single location or manufacturer.

Conclusion

Welding gas tanks is one part of the welding equation that becomes easy when you know all the size and specifications information. You should contact your local gas supplier for any queries beyond common practices. They will make every effort to be of assistance to you. Keep in mind that you might be their customer in the future.

Make sure you choose the right size tank to easily fill it up, or get one already filled in your area. We hope the above article will help you select your next project’s gas cylinder.