Ultrasonic welding is a variant of the friction welding process. In ultrasonic welding, the ultrasonic acoustic vibration is applied on the workpieces being welded to create frictional movement and frictional heat.

In this article, we will discuss the principle of ultrasonic welding, equipment, how it works, welding of plastics and other materials that can be welded by ultrasonic welding, advantages and limitations , application and safety considerations.

Principle of ultrasonic welding

You must have seen and experimented with a tuning fork in your high school days. What happens when you hit a tuning fork on a hard rubber? Correct, it vibrates as well as produces a humming sound. If the frequency of the tuning fork is 512 Hz, it means it vibrates 512 times per second. If you touch the vibrating fork ends to a light object (like a ping pong ball), the vibrating forks transmit the vibration to the ball, and the ball is pushed. And, if the ball is kept stationary, the vibrating fork transmits its vibration to the ball, and the ball starts vibrating. This basic idea is made use of in ultrasonic welding. However, the frequency of vibrations used is much higher.

If you see the dictionary, the term ultrasonic indicates sound waves that have a frequency above the maximum limit of human hearing, and the upper or maximum limit of hearing in average human adults is 15 to 17 kHz (kilohertz). The frequency used in ultrasonic welding is above 15 kHz (15,000 hertz (1 kHz = 1000 Hz)). You can define ultrasonic welding as a process of joining two parts (metal or thermoplastic) using the localized application of ultrasonic acoustic vibrations and pressure to generate frictional heat and bonding.

Ultrasonic welding equipment or machine

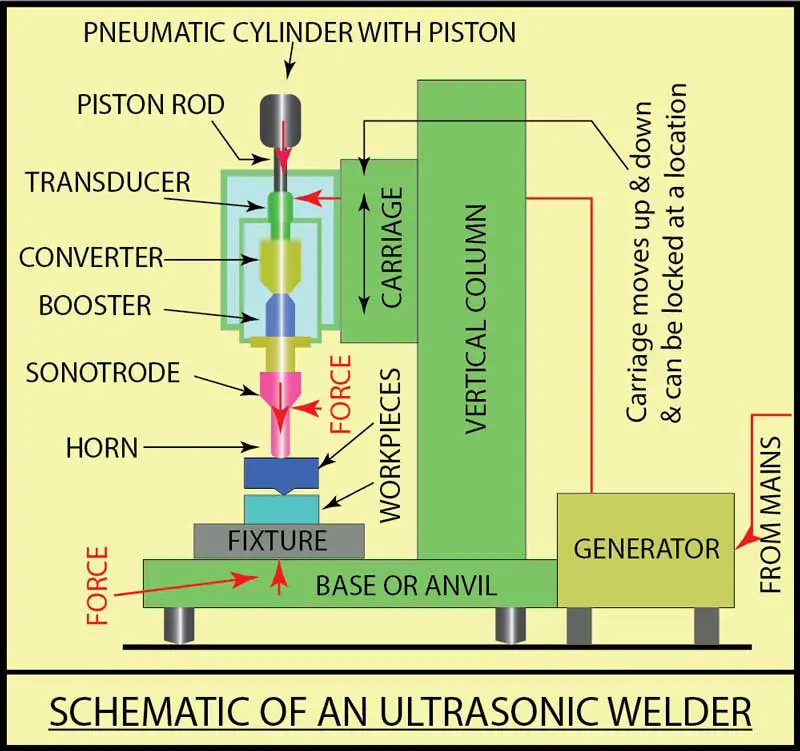

The ultrasonic equipment will have a provision to clamp the two workpieces under pressure, and the source of pressure can be a pneumatic or electric drive. The equipment has the following major parts:

- Generator.

- Base.

- Welding stack (Sonotrode system).

- Fixture, required for holding the workpiece.

1. Generator –The work of a generator is to convert the single-phase electrical power from the mains to the required frequency and voltage for the stack (transducer) that further converts it into mechanical vibrations. The generator takes the input power supply (50 to 60 Hz) and delivers a high-power electric signal to the stack (matching the required resonance frequency).

The microprocessor unit of the machine controls the welding cycle and gives the key welding information to the operator through the user interface. The operator can enter the required welding parameters using the user interface.

2. Base – The base of the machine is supported by adjustable height legs. The base supports the fixture for holding the workpiece, pneumatic cylinder for applying static pressure, and sonotrode system. Some people call the base “anvil.”

The machine has a pressure gauge with a regulator, and the required clamping pressure can be set using this (the required clamping pressure changes from welding to welding). Few manufacturers have replaced the pneumatic cylinder with the electromagnetic force, suitable for welding small and delicate parts.

3. Welding stack (sonotrode system) – Welding stack provides ultrasonic mechanical vibrations to the workpieces. The welding stack consists of a transducer or converter(piezoelectric transducer),booster, and horn. The converter, booster, and horn are tuned to resonate (vibrate) at the same ultrasonic frequency (15 kHz and above).

- Converter (piezoelectric transducer); converts the electrical signals received from the generator to mechanical vibrations using the piezoelectric effect. The transducer or converter does the work of converting electrical energy received from the generator to mechanical ultrasonic vibrations required for the welding process. The transducer has several piezoelectric ceramic discs inserted between two titanium metal blocks. There is a thin metal plate between each of the ceramic discs, and this is the electrode. When the generator feeds the electrical sinusoidal energy to the transducer through the electrodes, the ceramic discs expand and contract and produce an axial peak to the oscillatory movement of 10 to 20 microns (µm). Transducers are delicate parts and are to be handled with care.

- Booster; the booster does the job of amplifying the mechanical vibrations produced by the transducer and transferring them to the welding horn. The booster expands and contracts due to the ultrasonic energy received from the transducer. The booster enhances the amplitude of the vibration mechanically. The booster also clamps the stack in the welding machine.

- Horn; the welding horn transmits the mechanical vibrations to the welded workpieces, and its design and geometry are crucial for quality welding. Some welding horns have hardened tips to reduce the wear during welding. The geometric shape of the horn tip is made compatible with the shape of the parts being joined. The horn modifies the amplitude of the mechanical vibrations and applies it to the parts being welded. The horn is made from titanium or aluminum. The amplitude of the mechanical vibration of the horn ranges between 30 and 120 microns (µm). The shape of the horn should be able to take the stress caused by the axial expansion and contraction of the horn to avoid cracking during high amplitude applications. The tip of the horn transmits the ultrasonic energy to the workpieces, and hence the tip is designed to match the geometry of the workpieces (the profile of the horn tip is matched with the contour of the workpiece). Such an arrangement ensures maximum energy transfer between the horn and the workpieces.

4. Fixture and tooling – The fixture or tool mounted on the machine base clamps the lower workpiece and prevents its movement when the ultrasonic energy is applied to the top workpiece. Compact ultrasonic welding machines are available with a sonotrode system that can be held in hand, and the joining of parts can be done by manually spot welding.

How does ultrasonic welding works?

The ultrasonic welding can be used for the joining of metal and thermoplastics. Let us see the ultrasonic welding of metals first.

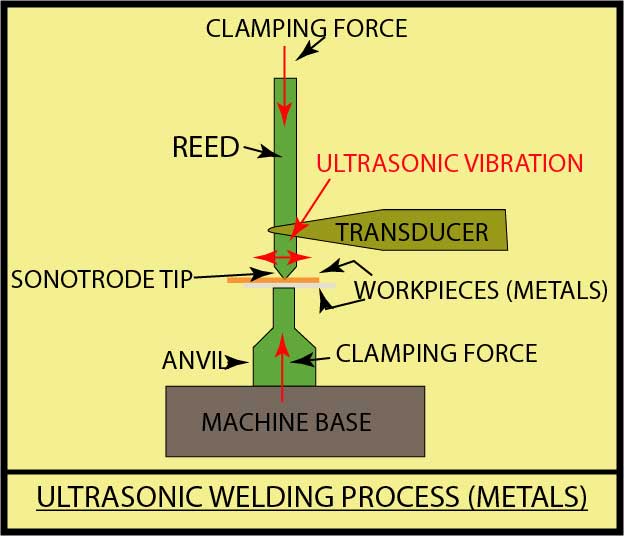

Ultrasonic welding of metals

Ultrasonic welding can be used only for lap joints of thin ductile metals (copper, aluminum, etc.). The metals to be joined can be a sheet or thin wire. The ultrasonic welding process comprises static clamping pressure, vibratory (shear) forces, and a moderate increase in temperature at the interface. The value or magnitude of these factors depends on the metal thickness, surface condition, and mechanical properties of the workpiece metals being welded.

The combination of static clamping pressure and the vibratory shear force causes elastic-plastic deformation at the interface. The continuous vibratory shear force at the interface allows the metal to metal contact at many points, and the contact area increases till the welding happens. Atomic diffusion occurs between the two workpiece metals at the interface, and recrystallization produces a fine grain structure with moderate work hardening. The magnitude of the welding parameters (clamping force, frequency, and welding time) depends on the thickness of the metal, surface condition, and mechanical properties. This process is suitable only for thin and ductile metals.

Ultrasonic welding is one of the solid-state welding processes. The frictional heat generated at the interface of the two workpieces is less compared to frictional welding. The temperature developed ranges from 30 to 50% of the melting temperature of the metal. The clamping force applied on the workpieces is static, and the shear force applied due to high-frequency mechanical motion is dynamic. The elastic-plastic flow of the material at the interface happens due to the frictional heat (0.3 to 0.5 of the melting temperature). Refining of grain structure and mild work hardening can occur in the heat-affected zone. The metallurgical bond between the two workpieces happens in the solid state.

Steps in ultrasonic welding of metals

The job Details: Joining of two thin aluminum strips by lap joint.

Preparation: The machine is to be set for locating and clamping the workpiece and for the parameters.

Step 1 – Ensure all the electrical connections and pneumatic connections are correctly made.

Step 2 – Clamp the fixture on the base. Ensure the side face of the horn is perpendicular to the base surface. The fixture mounted on the base has to be adjusted for the width of the workpieces. Your machine may have an adjustable fixture that provides adjustment for locating and clamping the width of the metal strips or foils being joined. Adjust the fixture to the required width.

Step 3 – Adjust the parameters – Adjust the sonic frequency to the required level. Adjust other parameters needed by the machine, like time taken by the horn (sonotrode) to make one stroke, welding time, cooling time, amplitude (a measure of the workpiece movement during ultrasonic vibration), etc. Adjust and set the air pressure as required.

Step 4 – Check the stroke of the sonotrode and adjust it if necessary. During the welding process, the sonotrode comes down rapidly, touches the top workpiece, clamps the top workpiece metal against the bottom fixed workpiece under pressure, transmits the mechanical ultrasonic vibrations to the workpiece completes the weld, and goes up to its original position rapidly. The stroke of the sonotrode should be correct for proper clamping and welding.

Step 5 – The two metal strips are placed in the fixture (overlapping each other) and clamped.

Step 6 – You can press the foot pedal for the sonotrode to come down, clamp the upper workpiece onto the bottom fixed workpiece, transmit ultrasonic vibration, complete the welding, and move up to its position. These operations happen as per the preset frequency and timings.

When welding metals, the ultrasonic vibrations are transmitted parallel to the plane of the workpiece metals. The frictional heat raises the temperature at the interface to 30 to 50% of its melting temperature and removes the oxides and films from the metal surfaces. The atoms of the workpiece metals move into each other and create a bond to hold the workpieces together. The welding cycle will be high-speed and may take less than a second. You can take out the welded strips and load the next set of metal strips for welding.

In an automatic machine, the loading and unloading of the workpieces and the welding cycle happen automatically.

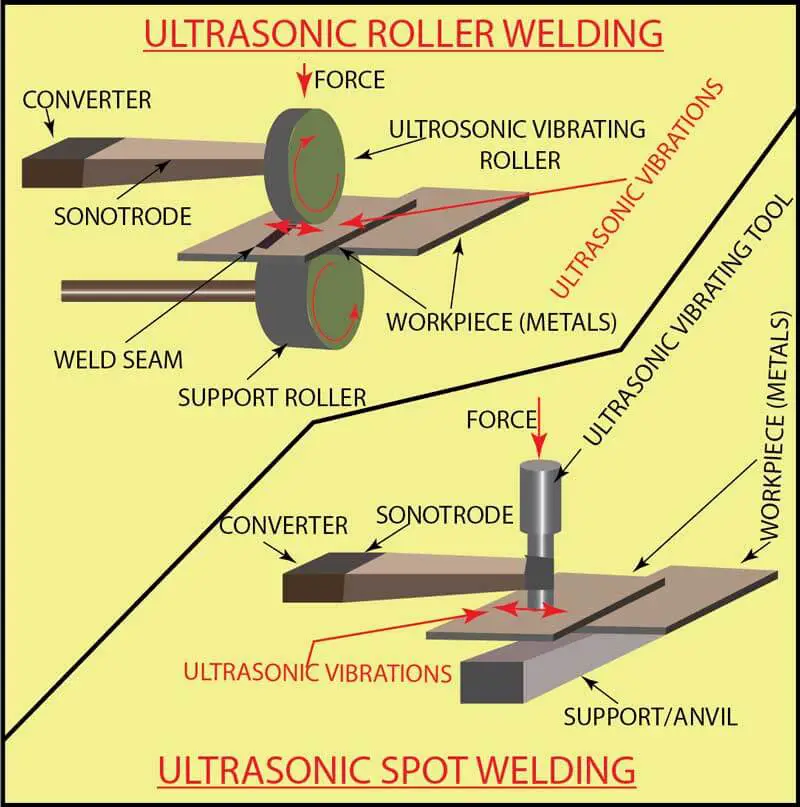

Variants of the ultrasonic metal welding process

- Ultrasonic spot welding – The horn tip has a pointed circular cross-section and creates spot welds.

- Ultrasonic line welding – The horn tip is thin and the required length (0.5 inches or 1 inch, etc.) and create line welds.

- Ultrasonic continuous seam welding – Here, the horn is in the form of a circular rotating disc, and the seam welding is accomplished by moving the workpiece metals under it. The concept of seam welding can be extended to seam welding of two hollow thin section pipes by the peripheral movement of the two pipes under the circular rotating horn. This method of welding is called ‘ultrasonic roller welding.’

- Ultrasonic process variables – The process variables in ultrasonic welding are ultrasonic power, clamping pressure, and welding time (speed).

Ultrasonic welding of plastics

Ultrasonic welding of plastics is a method of joining two injection molded thermoplastic workpieces by using the heat generated from very high-frequency mechanical vibrations. This uses ultrasonic mechanical vibrations or oscillations to create the frictional heat at the interface. The mechanical vibrations are produced by the welding sonotrode (also called horn). The workpieces to be joined are clamped under pressure and subjected to mechanical vibrations at a frequency of 15 to 40 kHz (kilohertz).

The success of the welding depends on the design of the welding equipment, the mechanical properties of the thermoplastic parts being welded, and the joint design in the parts. The process of ultrasonic welding is very fast and is ideal for mass production. Ultrasonic welding is widely used to produce light parts for automobiles, consumer electronic products, and smartphone casings. The surface of the plastic workpieces to be joined should be plane and without any distortion or warpage.

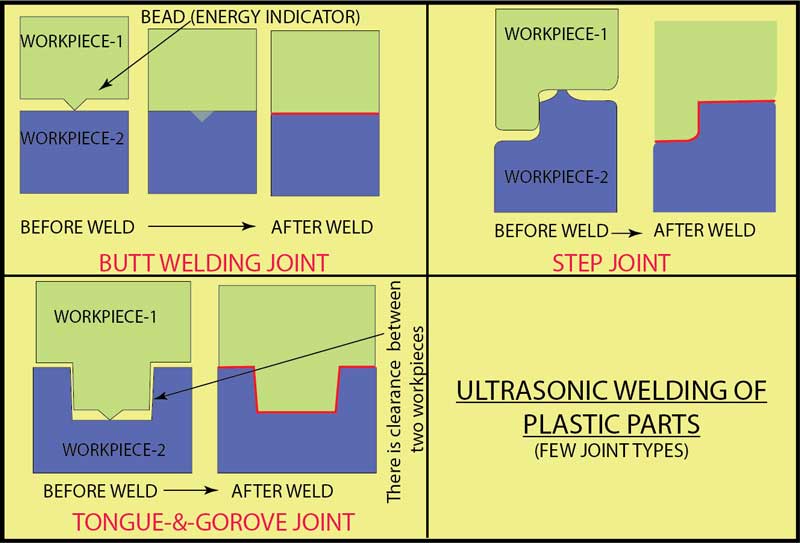

Narrow pointed raised sections or beads (called energy indicators) are molded on the surface of one of the workpieces. The raised sections help with the concentration of frictional heat and welding quality.

Types of joints – Step joints are preferred since it reduces the flash and enhances the joint strength.

The strength of the weld can be further increased by the tongue and groove joint; however, molding this type of joint in the workpieces is difficult. Creating a bevel on one of the workpiece surfaces works well in many metal welding processes. However, this is not recommended in ultrasonic welding since this process does not use a filler material. The resulting weld joint will be very poor.

Welding process – The ultrasonic welding equipment can be customized for joining injection molded thermoplastic parts. The parts are sandwiched between a special fixture mounted on the machine base (anvil) and a custom-shaped sonotrode (horn) connected to the transducer, and the amplitude of the acoustic vibration used can be upwards of 15 kHz (kilohertz). When welding thermoplastics, the interface of the two workpieces (being welded) are specially designed with one workpiece having one or more spike or energy director.

The frictional heat generated due to the ultrasonic vibrations melt the point contact at the interface and create the joint. The ultrasonic welding is typically applied for the joining of the parts used in smartphones, consumer electronics, toys, disposable medical aids, etc. Ultrasonic welding is useful for welding hard and soft plastics (semi-crystalline plastics) and metals.

Steps in ultrasonic welding of plastics

Step 1 – The thermoplastic parts to be welded are mounted on the fixture clamped onto the anvil. The bottom workpiece is clamped to make it stationary.

Step 2 – The sonotrode or horn comes in contact with the parts to be welded. Pressure is applied, and the horn clamps and holds the parts together.

Step 3 – The horn transmits the ultrasonic vibrations to the parts being welded, and due to the rubbing action, frictional heat is generated between the two parts at the interface. The vibration creates shear forces between the two parts being welded. The two parts are bonded together due to the heat generated and the clamping pressure.

Step 4 – The pressure is released, the horn moves up, and the welded part can be taken out from the anvil.

The time taken for the welding, the pressure applied, and the temperature generated is controlled by a computer or microprocessor, which is part of the ultrasonic welding equipment. In thermoplastics, the mechanical vibrations are applied perpendicular to the plane of the workpieces, and the frictional heat is generated at the interface. The plastic molecules from the two parts mix together to form the bond. The welding time can be as less as ¼ of a second.

Materials that can be welded by ultrasonic welding

1. Metals

Low thickness metals that are ductile and have low hardness can be ultrasonically welded. The preferred metals for ultrasonic welding are aluminum and copper. The capacity of the ultrasonic welding system defines the metal that can be welded. The process is limited to thin low hardness metal sheets since the high-energy ultrasonic welding systems are unavailable.

2. Thermoplastics

Ultrasonic welding between two thermoplastic parts is possible only if they are chemically compatible. If the parts are not chemically compatible, the materials may melt together, but there will be no molecular bond. One example is polyethylene and polypropylene, they are semi-crystalline materials, and many of their physical properties are the same. However, they are not chemically compatible and cannot be welded together.

Dissimilar thermoplastics can be compatible only when the difference in their melting temperatures is within 6ºC, and both have similar molecular structures. When two thermoplastics are chemically compatible for welding, other factors affect ultrasonic welding, such as hygroscopic (material that absorbs moisture from the atmosphere), mold release agents, lubricants, etc. The amount of clamping pressure and the intensity of vibration energy of an ultrasonic welding machine decide the metal and thickness of the metal that can be welded.

3. Other materials

Different fabric groups such as cotton, wool, silk, and many others can be joined together by using an adhesive film in between. For welding thermoset and thermoplastic parts, the thermoset parts should be made weldable by adding a layer of thermoplastic (on the welding surface) during its molding. The thermoplastic layer is often termed a coupling layer.

Advantages and limitations of ultrasonic welding

Advantages

- The ultrasonic welding process is quicker than the conventional process of joining thermoplastic parts with adhesives, and the process can be automated easily. The welding makes clean and precise joints. The low thermal impact on the materials involved enables a greater number of materials to be welded together.

- The heat-related issues in ultrasonic welding are negligible. Thin metals having low hardness are suitable for ultrasonic welding.

- Ultrasonic welding is fast, clean, efficient, and can be easily automated for high consistency and mass production.

- The process does not require a filler metal or adhesive or mechanical fasteners and the finished workpieces are strong.

- This process does not damage the surface finish of the thermoplastic parts being welded.

- The investment required for ultrasonic machines is not high.

- This process can bond thermoplastics better, faster, and cheaper than any glue.

- The workers are not exposed to harmful gasses or radiation when working on ultrasonic welding equipment. The high-frequency sound emitted by the system can be overcome by wearing ear protection.

- This process is environmentally friendly.

- Very low thermal impact on the workpieces (very low heat affected zone).

- No special ventilation is required for the welding area.

- Creates hermetic and tamper-proof seals.

- Power consumption is considerably low and works on a single-phase supply.

Limitations

- The depth of ultrasonic welding is less than one millimeter, and hence this method can be useful for welding thermoplastics and thin ductile metal foils and wires only.

- Ultrasonic welding works best for joining similar plastics and metals. This process can be used for welding dissimilar thermoplastics only if they are chemically compatible.

- This process is limited to lap joints of metal parts or special joints prepared for welding thermoplastic parts.

- High tooling and fixture cost. However, this can be amortized over a large number of parts when used for mass production.

- Not suitable for joining large thermoplastic parts.

- It emits high pitch audible noise, and the operator needs to wear ear protection.

Application of ultrasonic welding

Ultrasonic welding finds its application in the electrical and electronics industry, including computers, automotive industry, aerospace industry, medical, packaging, nuclear parts, etc. Ultrasonic welding is popular for joining thermoplastic parts. Ultrasonic welding is beneficial for building complex or small thermoplastic parts (using two or more injection molded parts), which are difficult or costly to do using a single injection molding method.

In the case of metals, however, ultrasonic welding is suitable for welding thin ductile metals only. Using ultrasonic welding, thin sheet metal, foil, wires, microcircuit connections, and meshes can be conveniently bonded.

Electrical and electronics industry (including computers): Welding of microcircuits (transistors and diodes are connected by thin aluminum/gold wires using ultrasonic welding) and is also used for bonding wires and chips in the microcircuits. The ability of ultrasonic welding to weld dissimilar metals is advantageous here.

Automobile industry: Automobile door panels, instrument panels, steering wheels, keys, parts of the headlamp, switches, buttons, and many other large sizes plastic parts in an automobile. The advantage of ultrasonic welding here is that it does not damage the surface finish of the two or three thermoplastic parts being joined, which is essential in an automobile (from an aesthetic angle).

Aerospace industry: It is difficult to weld aluminum by traditional welding methods. However, ultrasonic welding can easily weld thin aluminum parts. Aluminum is extensively used in the construction of aircraft and spacecraft, and ultrasonic welding is a necessary process used in the aerospace industry.

Medical industry: Ultrasonic welding is used to manufacture blood filters, IV catheters, dialysis tubes, face masks, etc. Ultrasonic welding preserves the hygiene of the parts since this process does not contaminate or degrade the welded components. Ultrasonic welding is suitable for automation, and hence the pieces can be welded at a high rate of production and low unit cost. Ultrasonic welding is used to produce many textile products used in the medical industry, such as masks, hospital gowns, etc.

Packaging industry: The very common example of ultrasonic welding in the packaging industry is the blister pack, popularly used in the pharmaceutical industry, food, and consumer goods industry. Ultrasonic welding is also used for packing dangerous items like crackers, explosives, and highly reactive chemicals.

Food industry: The food industry prefers ultrasonic welding over the traditional joining techniques since it is fast, hygienic, and can produce hermetic seals. The ready-to-use juice or flavored milk containers are sealed using ultrasonic welding, and here the parts of the paper container are coated with polypropylene or polyethylene. Examples of other ultrasonic welding sealed food items are bar chocolate and candy wrappers, frozen food packs, etc.

Other applications: Sports shoe companies use different materials like synthetic suede, mesh, and others to make the shoe light, flexible, breathable, and long-lasting. The shoe companies used the method of stitching earlier and now switched over to ultrasonic welding by inserting polymer films in between. The ultrasonic welding has drastically brought down the production time per shoe.

Safety Considerations

The operator must operate the ultrasonic machine taking all the safety precautions suggested by the manufacturer. There is a risk of high voltage and moderate heat. You should never take your hands near the welding area since they will be under high vibration. You must wear hearing protection and eyeglasses. There can be a high-pitched squealing sound near the machine (due to the ultrasonic vibrations), and an acoustic enclosure for the machine can safeguard the people nearby.

Final thoughts

Ultrasonic welding is a rapidly developing process, and with continuous research and development, its utility will increase in the future.

References: