Tungsten electrode is the TIG welding process consumable that works as a terminal for the electric arc to generate the required heat to join the two metal pieces. Tungsten electrode sharpening is a critical process to produce the required electrode shape, which affects arc starting, weld penetration, arc shape, and electrode life.

A great tungsten electrode is essential for a good TIG weld bead in terms of shape and penetration. The selection of the right type and good quality tungsten electrode is not the only factors influencing the appearance of the welding. Grinding and sharpening tungsten electrode has a significant role in having an excellent weld bead from your TIG welding.

If the tungsten electrode is not sharpened correctly, you could face many issues during welding resulting in an unclean and weak weld. Therefore, for the best performance of TIG welding, the tungsten electrode is usually sharpened before welding starts.

It is essential for you, as a TIG welder, to know how to grind your tungsten electrodes properly to get the best result out of your welding. You may equip yourself with the proper grinders and sharpening tools to make your life easier.

So, let us look at how to sharpen tungsten electrodes properly so you can unfold the full effect of tungsten electrodes.

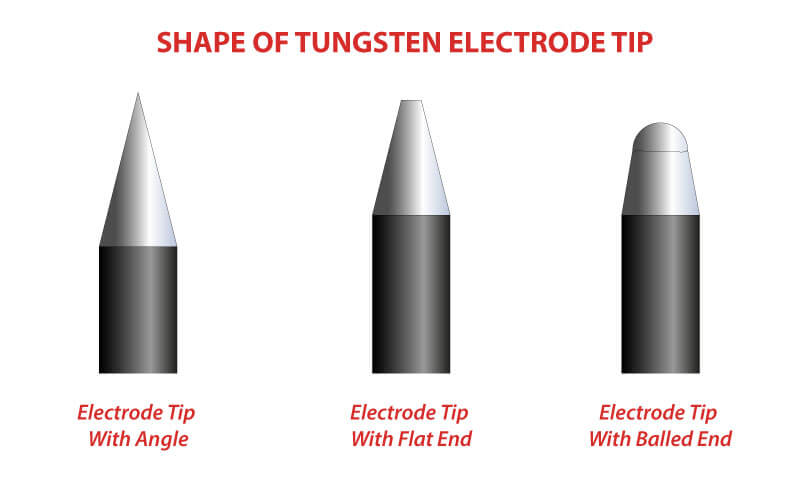

The shape of the tungsten electrode tip

The tungsten electrode shape and geometry is an essential parameter in TIG welding that affects the arc starting and shape. Hence, it affects the shape of the weld bead and its penetration. Therefore, the electrode’s geometry is a welding variable that is considered during developing Welding Procedure Specification (WPS).

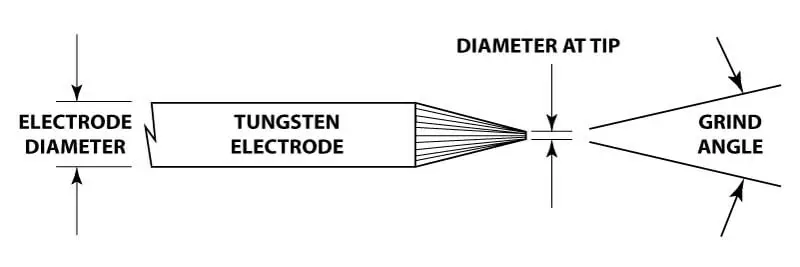

With DCEN (Electrode Negative) welding, you need to sharpen the tungsten electrodes to a specific angle. As a general rule, the length of the angle of the electrode tip is equal to approximately 2 to 2.5 times the electrode diameter.

With AC welding, you need to create balled shape of the tungsten electrode tip. To produce a ‘balled’ end, an arc initiated with the electrode connected to the positive side of the welder, the current increased until it melts the tip of the electrode.

3 tips to correctly sharpen tungsten electrodes

Step 1: Cutting tungsten to length

Tungsten alloys used in tungsten electrodes are very brittle because of their high hardness. Therefore, they can easily splinter or shatter, causing the tungsten electrode to fracture.

The fractured tungsten electrodes can cause welding arc instability and break off during welding, leading to many safety and weld quality problems.

Cutting the tungsten electrode is always neglected whenever discussing electrode preparation steps. However, it is essential, and missing with it may cause various issues.

Cutting is usually done to adjust the electrode to a specific length or to remove the contaminated tip. Either way, whenever you cut the electrode, you need to ensure cutting it correctly.

Incorrect cutting of tungsten electrodes may damage the integrity of the tungsten alloys and increase the potential of tungsten breaking off during welding, causing the welded joint to be contaminated with tungsten.

Preparing the electrode can be done by regrinding it to remove the defective part whenever the electrode is slightly contaminated. However, if the electrode is completely contaminated, then you need to cut off the contaminated portion.

The main points you need to consider during electrode cutting operations are:

- Use a clean diamond wheel to produce a clean and smooth cut.

- Always secure the electrode on both sides of the cut to avoid bending it.

- Never bend the electrodes till they fracture.

- You should not notch the electrode by the grinder and snap it off.

- Try to avoid using a wire cutter or pliers to cut the electrodes and use the following recommendation.

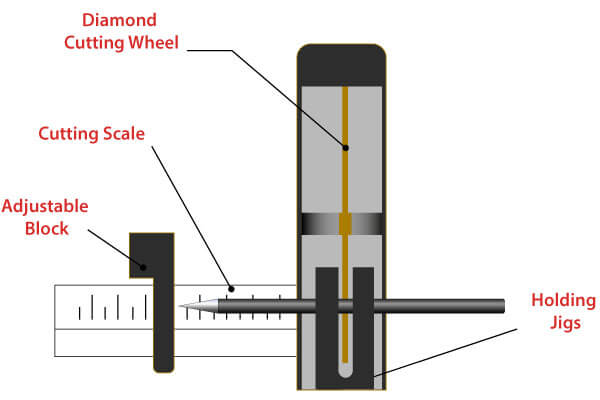

The proper way to reduce the tungsten electrode length or remove the contaminated portion is to fit the electrode rigidly on the cutting jigs, supported on both sides of the cutting line, as illustrated in the following illustration.

You should use a diamond cutting wheel to cut tungsten electrodes to ensure clean and smooth cuts and prevent the electrode from getting fractured or splintered.

The diamond cutting wheel should always be clean and free from any dirt or contamination to produce smooth and clean cuts and avoid contaminating the tungsten.

Step 2: Tungsten electrode sharpening (beveling and grinding)

The tungsten electrode shape and geometry is an essential parameter in TIG welding that is considered during developing Welding Procedure Specification (WPS).

Tungsten geometry affects the arc starting and shape, and hence, it affects the shape of the weld bead and its penetration.

In AC welding, pure or Zirconiated tungsten electrodes are usually used. You need to create balled shape of the tungsten electrode tip.

To produce a ‘balled’ end, an arc initiated with the electrode connected to the positive side of the welder, the current increased until it melts the tip of the electrode.

For DC welding, Ceriated, Lanthanated, or Thoriated tungsten electrodes are usually used. You need to sharpen the tungsten electrodes to a specific angle.

As a general rule, the length of the angle of the electrode tip is equal to approximately 2 to 2.5 times the electrode diameter.

When beveling the electrode tip, the desired end shape is obtained by grinding or using chemical compounds.

The angle degree is essential, and it is always recommended to follow the welding machine manufacturer’s suggested angle for optimal use of the welder. If the angle is not specified, you should optimize the tip angle to your particular welding operations.

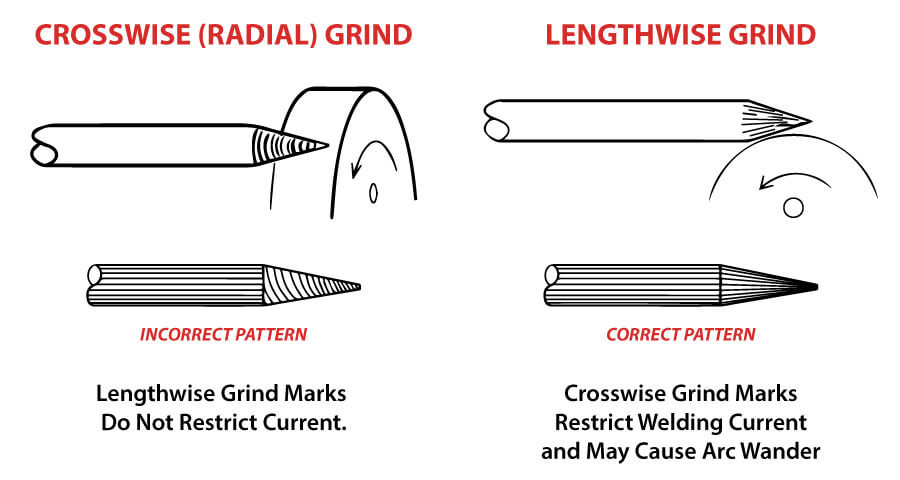

The most crucial point to remember during grinding for optimum arc stability is to grind the tungsten lengthwise (the axis of the electrode perpendicular to the axis of the grinding wheel).

Lengthwise grinding reduces the tungsten contaminating the weld and creates a pattern on the rod that does not strict the current and maintain arc stability.

The crosswise grinding restricts the welding current; restricting the current may cause the arc to wander and subsequently multiple welding defects.

The grinding wheel is recommended to be made of diamond and should be reserved for grinding tungsten electrodes to avoid contaminating the electrode tip with foreign metal or dirt.

Contaminated tungsten electrodes cause a lot of issues during TIG welding. These electrodes produce erratic arc, creating contaminated welds.

Though tungsten is a tough metal, the diamond wheel is harder than tungsten, which produces a smooth grind finish for the electrode. Using other types of wheels may create jagged edges and poor surface finishes that contribute to welding defects.

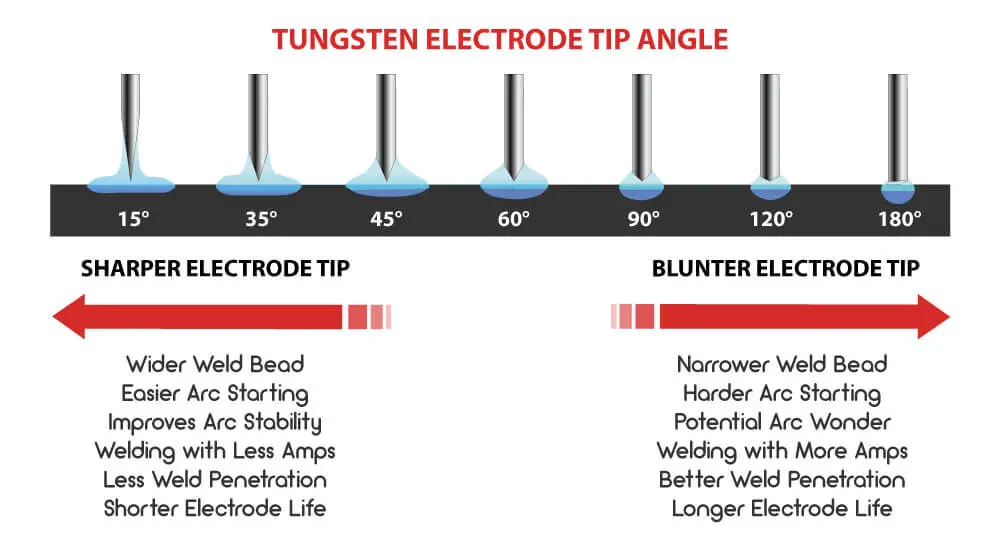

Sharp electrodes (small included angle) produce wider weld bead, easier arc starting, consistent arc, less weld penetration, and using less welding current.

Blunt electrodes (large included angle) produce narrower weld bead, harder arc starting, may create arc wondering, better weld penetration, can handle more current without eroding, and last longer.

The correct preparation of the tungsten electrode based on the current type and strength is vital for consistent welding with optimum performance. Once the electrode tip geometry is selected, you must maintain it consistent for the job material and thickness range.

Step 3: Tungsten electrode tip grounding

During TIG welding, the tungsten electrode temperature may rise to 5500 °F (3000 °C) or even more. Some welders prefer to ground flat the electrode tip to minimize the risk of the tip breaking off when initiating the arc or during welding.

Electrode tip breaking during welding will cause tungsten drops into the weld pool, creating a weld defect. Besides, it creates arc instability, which affects the weld’s integrity and may cause various defects.

For tungsten electrode tip grounding, after grinding the tapered portion, knock off the tip of the electrode by pointing it on the surface of the diamond wheel to remove the sharp point.

Tungsten electrode sharpening tools

Several sharpening and grinding tools are available on the market that performs tungsten electrode sharpening. Each tool has its benefits and drawbacks that you need to consider before you make your selection.

The sharpening tools can be categorized as follow:

- Specialized Tungsten Electrode Sharpeners.

- Sharpener/Grinder Head Tools.

- Bench / Angle Grinders.

- Chemical Tungsten Electrode Sharpeners.

Read also: Best Tungsten Electrode Sharpeners in 2026

1. Specialized Tungsten Electrode Sharpening

Many specialized tungsten electrode sharpener brands are available on the market. Either they come as a hand-held tool that is inexpensive but with limited adjustment capabilities or as an industrial tool. Industrial tungsten sharpeners offer many options and adjustment capabilities; however, they are more expensive and usually not affordable for general users.

The sharpeners come with slots or holes, typically sized 040″ all the way to 5/32″. The slots properly align the tungsten electrode with the grinding disc to produce the required finishes. Using these sharpeners is pretty easy. You need to pop the rod in, press the start button, and grind to the required level.

2. Sharpener/Grinder Head Tools

The sharpener/grinder head tools are attachments for rotary tools that sharpen electrodes. These attachments are less expensive than the dedicated sharpeners; however, they require rotary tools to use them.

You need to verify that the head tool can attach to your rotary tool before buying it. If you do not have a rotary tool or suitable rotary tool in your workshop, you may need to consider the prices of the head tool and the rotary tool together and compare with other specialized tungsten electrode sharpeners before you make your choice.

3. Tungsten Electrode Sharpening Using Bench / Angle Grinders

A bench or angle grinder is the most common tool used to sharpen tungsten electrodes. The grinder used to sharpen tungsten should be clean, have a fine hard stone, and use it for grinding tungsten only.

A coarse grinding stone may increase tungsten breakage and a poorer finish, affecting the welding arc’s stability. If the grinder is used with other metals than tungsten, particles of these metals trap on the tungsten and break free when the arc is started, resulting in contamination.

Light pressure should be applied against the grinding wheel during grinding to reduce the risk of accidentally breaking the tungsten.

Another way to grind tungsten is to use an angle grinder; however, angle grinders are not the ideal way to do so. The risk of contaminating the tungsten rod comes when using an angle grinder because of the variety of tasks for which we normally use the grinder.

Apart from contamination, it is hard to get a consistent grind angle and finish with the angle grinder. Hence, the angle grinder should be your last option and when you do not have any alternatives.

4. Chemical Tungsten Electrode Sharpening

The chemical sharpening method is pointing tungsten electrodes using chemical compounds. The tungsten is heated by shorting it against metal pieces by any heating source before dipping in the compound.

The chemical is a strong alkaline that dissolves the hot tungsten. The chemical reaction between the tungsten and compound creates additional heat to keep the tungsten hot. The tungsten rod is then cooled and cleaned before using it.

You need to be careful when using this grinding method of the fumes that come out of the process that may affect your health.

Our final verdict

In this article, we have tried to give a complete overview of tungsten electrodes sharpening and how it has a significant influence on the result of your TIG welding.

Sharpening tungsten electrodes is not a difficult task, and with one of the above tools, you can accomplish the job efficiently and super-fast.

You only need to remember the tips and tricks we discussed, especially clean grinder, cross-length grinding, and proper bevel angle, and you are set to go for your next amazing weld bead.

References: