Embrittlement is the loss of material ductility, making the material brittle; the phenomena result from a physical or chemical change. Hydrogen embrittlement is a loss of metal ductility and being brittle resulting from absorption of hydrogen, the amount of the absorbed hydrogen defines the degree of material embrittlement.

The phenomena result in various material defects such as hydrogen-induced cracking, hydrogen-induced Stress cracking, environmentally assisted cracking, and stress corrosion cracking.

Hydrogen Embrittlement

Hydrogen embrittlement tends to be significant when it leads to cracking, which is known as hydrogen cracking. Hydrogen cracking is usually associate with the weldment joint. When the material has susceptible (brittle) microstructure and hydrogen presences in the weld metal with the residual stresses associated with the welding process at a certain temperature range, hydrogen cracking starts to form.

The hydrogen cracking occurs after welding, on time interval usually range from several minutes to several months. The factors affecting this time interval are base metal chemical composition, weldment developed microstructure, weldment geometry, base metal thickness, degree of cold working, and gas content level.

Development of hydrogen cracking starts at outer surfaces of the weldment and heat affected zone when the following factors occur simultaneously:

Hydrogen Level

The hydrogen usually presents in the weld metal from the moisture in the electrodes flux coating, moisture present in the shielding gas, rust/scale and oil/grease in the weld zone, and other sources. The crack formation occurs whenever the hydrogen level reaches a sufficient degree of 15ml/100g of weld metal deposited. The hydrogen gets deposited in the weld molten metal and then transfer to the heat-affected zone by diffusion.

Tensile stresses

The stress associated with the welding process due to the thermal contractions during the weld cooling phase associated with other stresses. The crack formation occurs whenever the tensile stress is higher than 50% of the yield stress.

Temperature

Hydrogen cracking occurs after several hours of welding completion when weld and weld zone temperature reaches close to ambient temperature. The crack formation takes place whenever the temperature is less than 250°C for most steel grades.

Susceptible Microstructure

Due to the elevated temperature associated with the welding process, heat affected zone develops microstructures, which are usually harder and more susceptible to hydrogen embrittlement. The crack formation takes place whenever the metal hardness is greater than 400HV.

Hydrogen Embrittlement Cracking Types

Hydrogen embrittlement cracking is known technically as hydrogen-induced cold cracking (HICC); however, based on the other characteristics, the hydrogen cracks are known with the following names:

- Stress Corrosion Cracking (SCC) is the hydrogen cracking that develops in a corrosive environment under the influence of tensile stress.

- Heat Affected Zone (HAZ) Cracking is the hydrogen cracking that develops in welding heat affected zone.

- Cold Cracking is the hydrogen cracking that develops when the weld cools down.

- Delayed Cracking is the hydrogen cracking that develops several hours after welding completion (Usually 24~48h).

- Sulphide Stress Cracking (SSC) is the hydrogen cracking that develops in environments containing hydrogen sulfide.

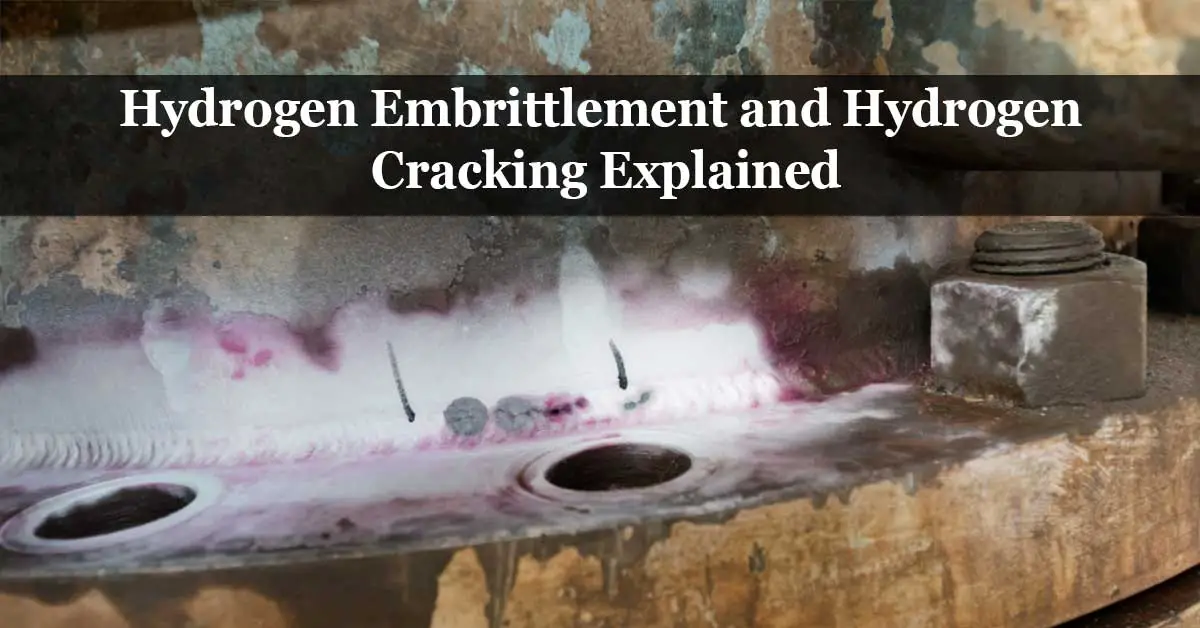

How to Determine Hydrogen Cracking Formation

The two common methods to determine and record hydrogen crack formation are acoustic emission analysis and hydrogen-induced cracks implant test.

Acoustic Emission Analysis

The analysis determines the growth of microscopic hydrogen cracks by using the acoustic emission technique. Sensitive microphones are placed at different locations on the weldment joint. The microphones catch the emitted high-frequency acoustic pulses caused during crack formation and crack growth and record it.

After analyzing the emitted frequencies, the origin of the crack can be localized and determined.

Implant Test

The test is conducted by preparing a specimen from the base material, welding it so that the formed heat-affected zone is identical to the weld joint heat-affected zone.

The specimen is exposed to a constant tensile load till cracking under certain defined conditions. This testing method is suitable for the comparison of base materials.

How to Prevent Hydrogen Cracking

As previously mentioned, hydrogen cracking development occurs when the four main factors (hydrogen level, tensile stresses, temperature, and susceptible microstructure) occur simultaneously.

To prevent hydrogen cracking formation, at least one of the factors should not be active during welding.

The following are the methods to control and minimize the influence of each factor:

Control Hydrogen Level

The main source of hydrogen is moisture present in electrode coating, welding flux, surface rust or scale or oils, and welding greases.

Methods to reduce hydrogen level are:

- Using coated electrodes, flux-cored wires, and Submerged Arc Welding (SAW) fluxes, which are low in hydrogen.

- Proper storage and baking of electrodes and fluxes as per manufacturer recommendation.

- Control the amount of moisture present in the shielding gas.

- Ensuring the weld zone is clean from oil and grease, dry, and free from rust and scale.

- Check the diffusible hydrogen content of the weld metal and follow the proper welding procedure specification.

Control Tensile Stress

Welding thick joints can raise the tensile stresses on the joint to the steel’s yield strength level. The control of the stresses is a challenging process.

Methods to reduce the influence of residual stresses are:

- Proper joint fit-up before welding is essential to avoid stress concentrations.

- Avoid poor weld profile.

- Perform stress relief heat treatment procedure for weld joints.

- Reduce welding heat input.

Control Susceptible Microstructure

The control of susceptible microstructure is based on the control of metal hardness by controlling the material chemical composition and cooling rate.

Methods to avoid susceptible microstructure are:

- Use steel with low carbon equivalent value (CEV) for carbon and carbon- Manganese steel; the higher the CEV, the greater the material is susceptible to hardening and hydrogen cracking.

- Avoid welding rapid cooling that would produce material hardening by using proper welding heat input.

- Apply preheating procedure and control welding inter-pass temperature between welding passes to allow the joint to cool slowly and void material hardening.

Control of Temperature

The crack formation occurs whenever the weld temperature reduces to less than 250°C for most steel grades. When the weld temperature is above 300°C, hydrogen tends to diffuse quite rapidly and escape into the atmosphere.

Methods to reduce the influence of low weldment temperature are:

- Apply preheating procedure and control welding inter-pass temperature between welding passes to avoid rapid cooling.

- Perform welding post-heat procedure to 250°C temperature for few hours to facilitate hydrogen escape (not to be confused with PWHT).

Conclusion

Although most hydrogen cracks occur in the weld heat-affected zone, there are circumstances when they may form in the weld metal. Hydrogen cracks can be avoided by controlling the moisture content in the electrode coating and welding fluxes and perform re-drying whenever deemed necessary. Controlling metal and specifically heat-affected zone hardness is crucial, and slow cooling of welding by preheating and post-heating procedures are the most effective ways to minimize the risk of hydrogen cracks.

Steel is the most susceptible material to hydrogen embrittlement compared to alloys with different crystal structures; however, to a certain extent, hydrogen can embrittle most engineering alloys.

References:

- TWI-Global: The Welding Institute (Various publications).