Oxy-fuel welding, more commonly known as oxyacetylene welding, or gas welding, is a welding process where two metal parts are welded by heating with a gas flame formed by the combustion of a fuel gas with oxygen.

Acetylene is the commonly used fuel gas, and when correct proportions of oxygen and acetylene are mixed in a gas welding torch, you will get a hot flame of around 3200º C.

You can vary the proportion of acetylene and oxygen to get the desired type of flame. Gas welding can be done with or without using a filler material.

Other fuel gases like propane, hydrogen and natural gas can be used for gas welding lower melting point metals like nonferrous metals, brazing, and silver soldering.

Types of flames in gas welding

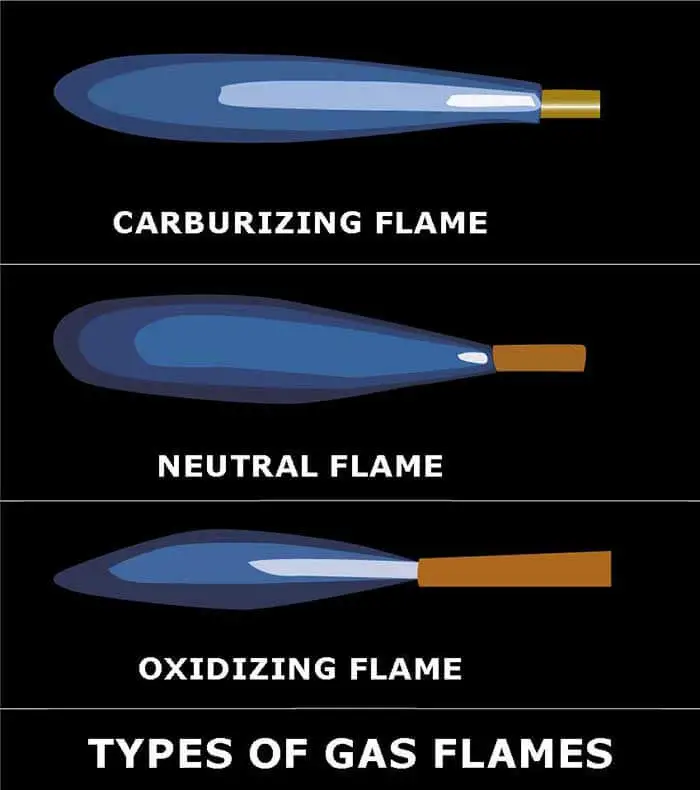

There are three different types of flames in gas welding, neutral, carburizing, and oxidizing. The welder can adjust the oxyacetylene flame by adding more or less oxygen to the acetylene flame based on the job requirement.

1. Neutral flame

This flame type is chemically neutral. The gas welders use the neutral flame as the starting point as it is so easily defined compared to all other flames. Therefore, the neutral flame is the most commonly used flame for gas welding or cutting.

In the neutral flame, the acetylene gas is completely burned in the oxygen and the surrounding air. The welder starts with opening the acetylene on the torch body, igniting the flame, and then slowly opens the oxygen valve to have two flame zones.

A neutral flame has a light blue inner cone and a dark blue (fading to colorless) outer cone.

The inner cone is where the acetylene and oxygen combine and partly burn to hydrogen and carbon monoxide. The tip of the inner cone is the hottest part of the flame where the temperature reaches approximately 6,000 °F (3,300 °C), providing enough heat to melt steel.

The outer cone is where the acetylene and oxygen combine with more oxygen from the surrounding air and burn.

The neutral flame has oxygen and acetylene in equal proportions, and it is metallurgically neutral. The neutral flame is usually used for heating, cutting, and steel gas welding.

2. Carbonizing flame

Excess acetylene added to the neutral flame creates the carburizing flame. Carburizing flame has three zones, the hotter inner cone, a white-hot zone (acetylene feather), and the blue-colored outer cone.

In the carbonizing flame, the acetylene gas is partially burned in the oxygen, and the flame forms when oxygen is first added to the burning acetylene.

The incomplete combustion of the acetylene causes an excess carbon in the flame, creating what is called the feather.

The flame feather is typically two to three times the length of the inner flame cone, the feather length and made ever smaller by increasing the amount of oxygen in the flame.

Due to the acetylene’s incomplete combustion, the flame temperature drops to approximately 5,000 °F (2,800 °C). Besides, the unburned carbon may dissolve in the molten metal and hence carbonize it.

The carbonizing flame removes the oxygen from iron oxides creating a soft flame known as a “reducing flame.” The reducing flame is typically used for gas welding aluminum and aluminum alloys, soft soldering, and hard-facing metals.

3. Oxidizing flame

Excess oxygen added to the neutral flame creates an oxidizing type of flame. The flame forms by increasing the oxygen ratio in the neutral flame.

The oxidizing flame is slightly hotter than the neutral flame, and carbonizing flame as the combustible gases will have a sufficient amount of oxygen.

The oxidizing flame affects metals and therefore is usually not preferred to use in most applications. The oxidizing flame creates unwanted oxides to the structural and mechanical detriment of most metals.

The oxidizing flame is shorter and sharper than the neutral flame. The inner cone of the oxidizing flame gets pinched and smaller at the tip and a purplish tinge, and the flame sound becomes harsh.

The oxidizing flame is used in brazing, bronze-surfacing, gas welding cast iron, brass, bronze, and zinc alloys.

Also read: A Detailed Guide To Oxy-Fuel (Oxyacetylene) Welding

Conclusion

You can weld or join two pieces of metal in various ways; however, gas welding is one of the oldest forms of heat-based welding, and even today, gas welding is the only process that can be used when there is no electricity.

Despite many advanced welding processes available today, oxy-acetylene gas welding is popular even today for welding thin steel sheets, for preheating a part, for hot bending, for doing brazing/soldering, and for doing the repair job.

There are three types of flames in gas welding, neutral, carburizing, and oxidizing. The welder can adjust the flame by adding more or less oxygen to the acetylene flame. Each type of flame has its feature and uses, as discussed above.

The low cost of the equipment, portability and lower welder skill level make gas welding one of the most popular welding processes.

References: