When it comes to boating, understanding a boat’s various components and parts is essential for smooth sailing. One such component is boat bellows, which often remain unnoticed but play a crucial role in maintaining the boat’s integrity.

In this article, we will dive into the world of bellows on a boat, exploring what they are, their significance, and their maintenance. So, let’s get started.

What are Bellows on a Boat?

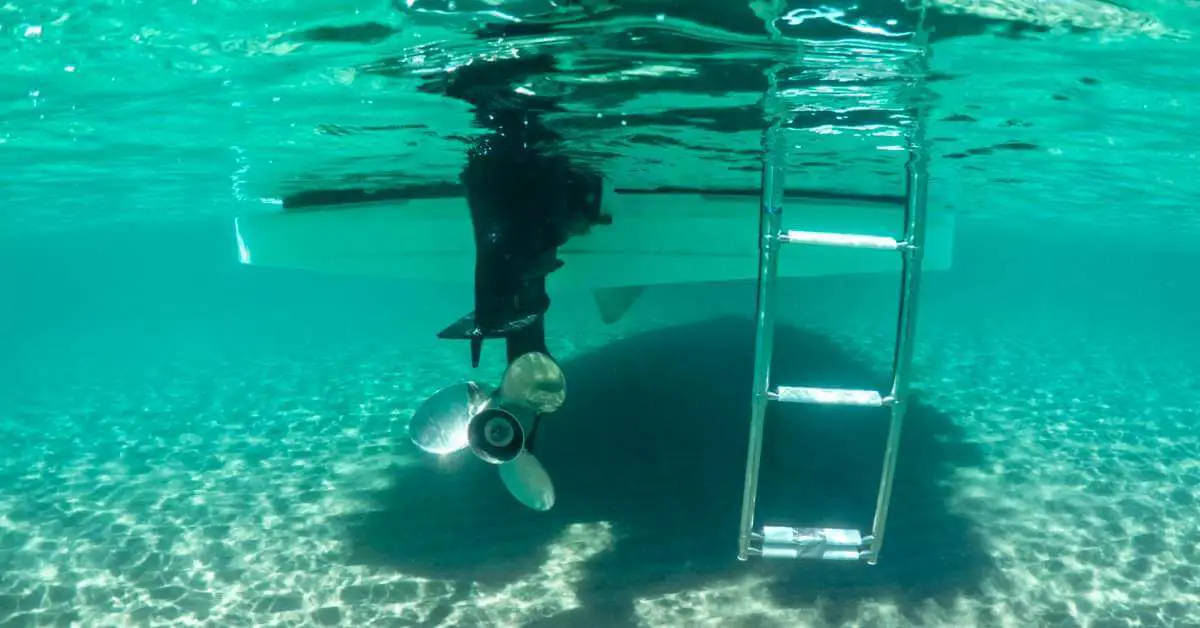

Bellows are flexible, rubber components shaped like accordions that prevent water from entering boat engines. Bellows provide watertight protection against rusting by creating a flexible seal over engines and other internal systems used in open-water cooling systems.

They are often found in stern drives and outboard motors. Bellows help seal the area where the upper and lower parts of the drive join together, ensuring the boat remains buoyant and safe.

The bellows’ accordion-like structure allows them to articulate as the engine operates, maintaining the watertight seal. They also help provide a smooth and flexible connection between different parts of the boat, compensating for misalignment and reducing vibrations and noise.

Bellows can be made from different materials, such as rubber, neoprene, or silicone. Rubber bellows are the most common, as they are durable and affordable, making them an excellent choice for boats.

Different Types of Boat Bellows

Each of these bellows plays a critical role in ensuring the proper functioning of various systems on a boat. They have to withstand the harsh marine environment, including exposure to moisture, salt, sunlight, and temperature fluctuations. Here are the common types of boat bellows:

1. U-Joint Bellows

U-joint bellows are typically located at the end of the drive shaft, where it connects to the stern drive or outboard motor. They are designed to seal the area between the engine and the stern drive to prevent water and debris from entering.

U-joints bellows also absorb and dampen vibrations caused by the engine and drive system. These bellows are made of flexible materials such as rubber or neoprene, allowing some movement while providing a tight seal.

2. Exhaust Bellows

Exhaust bellows are an essential component of the boat’s exhaust system. They are usually installed between the exhaust manifold or riser and the stern drive or transom.

The primary function of exhaust bellows is to prevent water from entering the engine through the exhaust system. They do this by creating a watertight seal allowing exhaust gases to exit the boat while keeping the water out.

3. Shift Cable Bellows

Shift cable bellows are located around the shift cable on a boat. The shift cable connects the controls at the helm to the stern drive or outboard motor, allowing the operator to shift gears.

Shift cable bellows are designed to protect the internal mechanisms of the shift system from water intrusion. They help maintain the integrity of the shift cable and prevent corrosion or damage that could affect the smooth operation of the shifting process.

Significance of Bellows on Your Boat

Propulsion shaft bellows are an integral part of a boat’s propulsion system and play a significant role in maintaining the boat’s overall structural integrity. Here are the key reasons why they are significant:

1. Preventing Water Ingress

One of the primary functions of bellows is to create a watertight seal, keeping water out of the boat. Water ingress is a common problem for boats and can cause significant damage if not addressed. Bellows provide a tight seal around drive shafts and other components, helping maintain the boat’s buoyancy and safety.

2. Protecting Internal Components

Bellows act as a protective barrier, shielding sensitive internal components from water damage, corrosion, and other external elements. Keeping the drive shaft and other sensitive parts dry help to prolong the lifespan of these components, ultimately saving costly repairs and replacements.

3. Reducing Vibrations and Noise

Bellows are designed to dampen vibrations and reduce noise levels generated by the boat’s propulsion system. By absorbing and minimizing vibrations caused by the engine, they provide a smoother and more enjoyable boating experience.

4. Compensating for Movement

Another significant advantage of bellows is their flexibility and articulation. The bellows can expand and contract as the engine vibrates and moves, compensating for misalignment and movements. This makes them an essential part of any boat’s propulsion system, helping maintain its structural integrity.

How to Avoid Problems With Your Bellows | Maintenance Tips for Boat Bellows

Proper maintenance of bellows is essential to ensure their longevity and effectiveness. With routine maintenance and proper care, you can avoid problems with your boat below and catch serious issues before they can cause damage to your boat. Here are a few tips to keep in mind:

1. Regular Inspection

Inspect the bellows regularly for signs of wear and tear, such as cracks, tears, or leaks. Addressing any issues promptly can prevent water ingress and potential damage to the boat. If you notice any signs of damage or deterioration, replacing the bellows immediately is important.

2. Clean and Lubricate

Clean the bellows regularly using mild soap and water to remove dirt or debris. Additionally, applying silicone-based lubricant can help maintain the flexibility and smooth operation of the bellows. Avoid using petroleum-based lubricants, as these can cause the bellows to deteriorate.

3. Replace if Necessary

If you notice any signs of damage or deterioration, it is crucial to replace the bellows immediately. Ignoring or delaying replacement can lead to water leakage, severely damaging the boat’s internal components. Bellows typically last between three to five years, depending on the type of material and usage.

4. Professional Assistance

If you are still determining whether to inspect or replace the bellows, it is always advisable to seek professional assistance. Boating experts can provide expert advice and guidance, ensuring your bellows are in optimal condition.

How to Replace the Bellows on Your Boat

To replace bellows on a boat, it is generally recommended to follow the specific instructions provided in the service manual for your boat’s make and model. However, here is a general overview of the steps involved in replacing bellows on a boat:

1. Gather the necessary tools and equipment: Before starting the replacement process, make sure you have all the required tools and replacement bellows on hand. Typical tools may include screwdrivers, wrenches, pliers, and a sealant suitable for marine applications.

2. Prepare the boat: To access the bellows, you will likely need to remove certain components such as the stern drive or outboard motor. Consult the service manual for your specific boat to determine the steps required for disassembly.

3. Remove the old bellows: Carefully disconnect, loosen and cut the old bellows from the corresponding components such as the driveshaft, exhaust manifold, or shift cable. Take note of any fasteners, clamps, clips, or gaskets that need to be removed and the order in which they should be removed.

4. Install the new bellows: Following the reverse order of removal, install the new bellows and ensure they are properly aligned and secured. Pay attention to any specific instructions or recommendations provided by the manufacturer.

5. Check for proper installation: Once the new bellows are in place, inspect the connections to ensure they are tight and leak-free. Additionally, check the movement and flexibility of the bellows to ensure they are functioning correctly.

6. Reassemble the boat: Put all the removed components back together according to the service manual instructions.

Conclusion

Understanding the importance of bellows on a boat is vital for every boating enthusiast. These rubber components play a crucial role in maintaining the integrity and safety of the boat by preventing water ingress and protecting internal components. By following the maintenance tips mentioned above, you can ensure that your bellows are in excellent condition, providing you with a worry-free boating experience.

The bottom line is that the bellows are essential in keeping your boat safe and operational. Regular inspection and maintenance are essential to ensure they remain in optimal condition, protecting your boat and enhancing your boating experience. So, watch your boat’s bellows and sail with peace of mind.