Welding burns can vary significantly in severity, from mild discomfort to intense pain that may lead to long-term damage if not properly addressed. Gaining insight into the distinct types of welding burns is essential not only to provide appropriate care but also to prevent further complications from arising.

Each type of welding burn calls for a particular treatment approach. This involves addressing thermal burns that result from contact with hot metal or molten splatters, radiation burns caused by exposure to intense ultraviolet light, and electrical burns stemming from contact with welding equipment or electrical currents.

Awareness of these various types of welding burns and their respective characteristics makes us take necessary precautions, safeguarding ourselves and others from potential hazards.

Identifying and Understanding Different Types of Welding Burns

Before diving into the prevention and treatment of welding burns, it’s crucial to recognize the various types of burns that welders often encounter, including flash burns and skin burns.

Flash Burns

Flash burns, also known as welder’s flash or arc eye, are among the most common types of burns experienced by welders. These burns result from exposure to ultraviolet (UV) radiation caused by the welding process. Various factors, such as the welding torches used and the type of welding performed, can influence the levels of UV radiation generated.

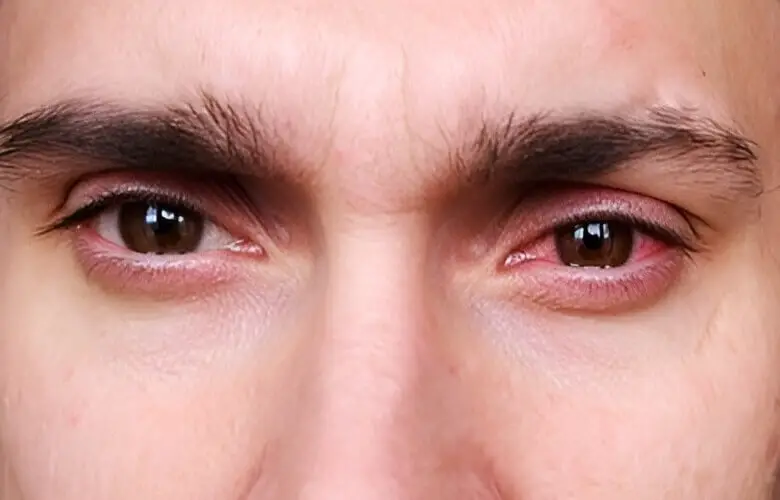

Flash burns, or UV burns, transpire when the eyes are briefly exposed to intense UV radiation during welding. The welding arc can damage the cornea (the clear front part of the eye), which is responsible for focusing light onto the retina for vision.

Excessive exposure to UV light can cause a range of symptoms. These types of burns are prevalent in TIG welding due to the high temperatures of the tungsten electrode wires, which are often hotter than the welding arc itself.

Flash burns can be more challenging to diagnose than visible skin burns, but common symptoms include mild to severe pain (usually starting a few hours after the incident), temporary vision loss, eye irritation, grittiness in the eyes, redness, and light sensitivity. The severity of these symptoms can vary and may persist for several hours or days.

Skin Burns

UV rays are similar to sunburn and arc welding burns. The intense heat generated during welding can cause thermal burns on the skin when hot metal or sparks come into direct contact with the skin. This contact results in pain, redness, and possibly blistering.

In addition to thermal burns, welding can also cause radiation burns on the skin. The welding arc emits UV radiation, leading to sunburn-like symptoms such as redness, itching, and pain on exposed skin. Inadequate protection during prolonged or repetitive exposure to UV radiation can heighten the risk of radiation burns.

Degrees of Welding Skin Burns

- First-Degree Burns: First-degree burns are the mildest, typically resulting from brief exposure to temperatures around 130 °F (55 °C). Characterized by red, tender, and painful skin without broken skin or blisters, these burns can be treated at home with proper care to prevent complications.

- Second-Degree Burns: More severe than first-degree burns, second-degree burns involve the outer (epidermis) and underlying (dermis) skin layers. These burns are marked by reddened, blistered, and painful skin, which may appear swollen. Medical attention is necessary for proper evaluation and treatment.

- Third-Degree Burns: The most severe of burns, third-degree burns penetrate deep into the skin, affecting nerves and blood vessels. The skin may appear charred, white, or leathery, and the affected area could be numb due to nerve damage. Immediate medical attention is required in such cases.

How to Treat Welding Burns

Here’s a systematic guide on how to treat welding burns, focusing on both flash and skin burns.

Flash Burns

Utilizing an Eye Patch and Orange Dye

Upon experiencing a welding burn, promptly sealing off the affected eye from potential hazards is crucial. For this purpose, eye patches are widely used, forming a protective barrier that guards the wounded eye against external irritants, aiding recovery.

The orange dye provides an essential diagnostic role in conjunction with the protective function. A few drops colored onto the injured eye highlight any potentially unseen damage or abrasions, allowing medical practitioners to assess the severity of the injury, thereby facilitating a more accurate treatment plan.

Implementing Dilating Drops

Administered dilating drops expand the pupil, allowing an increased influx of light into the eye. This can help mitigate symptoms like light sensitivity, blurred vision, and eye pain. Furthermore, dilated pupils help relieve muscle tension within the eye strain due to the burn.

Depending on the severity of the burn, the most suitable dilating drops can be prescribed by a healthcare professional for the patient.

Dressing the Burn

Appropriate care and vigilance are required in treating welding burns. In severe eye burn cases, a padded dressing might be necessary to form a protective cover, providing the eyes with rest and aiding in healing. Though it might initially seem inconvenient, this additional layer ensures further burn prevention and encourages faster healing.

Skin Burns

Treatment with Cold Water or Cool Compresses

To employ cold water in treating a burn:

- Carefully rinse the burn with cool running water for roughly 10 minutes.

- Ensuring the water isn’t cold is crucial as it could potentially exacerbate skin injury.

- If access to running water is impossible, resort to cold freezer water or a clean washcloth doused in cool water.

Cool compresses are another effective treatment method for welding burns. When dampened with cool water and gently applied to the burnt area, a clean washcloth or towel can effectively reduce pain and cool the skin.

Dressing the Burn

Acting as a safeguard, a dressing wards off external irritants from the burnt skin and lowers the risk of infection. It also alleviates pain and discomfort during the recovery process.

Antibiotic Use

To combat the harmful bacteria that may have infiltrated the skin via the burn, healthcare professionals often prescribe antibiotics, effectively reducing infection risk by eliminating the present bacteria and allowing the body’s natural defenses to concentrate on healing the burn. Antibiotics may also lessen inflammation and pain, providing relief to the patient.

Various commonly prescribed antibiotics for welding burns include topical ointments or oral medications. Topical antibiotics can be applied directly to the burn to prevent infection, while oral antibiotics can be used to treat more severe conditions.

Home remedies

For treating welding burns at home, several remedies can both alleviate pain and promote healing:

- Running Cold Water: Applying cold water instantly after a burn reduces pain and inflammation by constricting blood vessels and minimizing swelling.

- Aloe Vera: Applying the gel on the burnt area can soothe the skin and promote healing due to its anti-inflammatory properties.

- Over-the-Counter Pain Relievers: NSAIDs can help manage pain and inflammation. Always adhere to the recommended dosage and consult healthcare professionals before consumption.

- Honey: This household remedy, known for its antibiotic and wound-healing properties, when applied as a thin layer to the burn, can promote healing and hinder infection.

- Warm Compresses: After initial cold water treatment, a clean cloth dampened in warm water can provide soothing relief.

Please note: Home remedies provide temporary relief; severe burns necessitate seeking immediate medical attention.

How to Prevent Welding Burns

Here’s a systematic guide on safeguarding yourself from hazardous welding burns.

Utilizing Protective Gear and Clothing

- Flame-Resistant jackets: Primarily, ensure to don flame resistant jackets and welding aprons. Coupled with thermally-protective gloves, this ensemble affords robust defense against welding burns.

- Visor and Welding Helmet: Equipping the appropriate visor for the task is imperative. The ultraviolet light emanating from welding tasks is remarkably bright and poses a substantial risk to the eyes. Retinal flash burns are commonplace without the proper visor. Additionally, a welding helmet protects your face from intense heat and emits a shade lens that filters harmful Ultraviolet rays and infrared radiation. Safety goggles equipped with side windows protect your eyes against debris and flying sparks.

- Heavy-Duty Boots: Footwear with heavy-duty leather boots is essential to shield your feet from potentially harmful molten metal or sparks.

- General Safety Measures: Never overlook the importance of safety equipment, mainly when undertaking a welding job. Proper protective gear can effectively prevent serious burns.

Implementing Welding Screens or Curtains

The incorporation of welding screens or curtains around the workspace serves dual purposes. Firstly, it aids in preventing possible burns from sparks, molten metal, and debris on nearby colleagues or bystanders. Secondly, they help to contain the light generated from the welding process, alleviating eye strain without compromising your field of vision.

Maintaining Distance and Mindful Placement

- Safety Distance: A safe distance from the welding operation minimizes exposure to intense heat, sparks, and UV radiation. Adhering to the guidelines provided by the welding equipment manufacturer or your safety supervisor would help ascertain the ideal safe distance.

- Reflective Surfaces: Steer clear from highly reflective surfaces, such as polished metal, mirrors, or glass, which can reflect the intense light, sparks, and radiation emitted during welding, heightening the risk of burns and eye injuries. If working near such reflective surfaces is inevitable, use suitable shields or barriers to obstruct these reflections and ensure safe working conditions.

Routine Gear Check and Replacement

Regular inspections of your welding gear to detect any wear or damage are of utmost importance. Faulty or worn equipment fails to provide adequate protection and could compromise safety. Always replace damaged gear promptly to ensure its effectiveness in burn prevention.

FAQs About Welding Burns

How should I initially treat a welding burn?

Immediate treatment is crucial for welding burns. Start by rinsing the affected area with cold water to cool the burn and minimize pain. Avoid ice or freezing water, as this can further damage the skin. Remove any tight clothing or jewelry around the burn to prevent constriction, as swelling may occur. Seek medical attention if the burn is severe or covers a large area.

Can I use over-the-counter ointments or creams on welding burns?

Applying over-the-counter ointments or creams directly onto welding burns is generally not recommended without medical advice. However, natural remedies such as aloe vera gel or honey can be soothing and help promote healing. Always clean the burn thoroughly before applying any products, and consult with a healthcare professional for specific guidance.

When should I seek medical attention for a welding burn?

It is essential to seek medical attention for welding burns if they are severe, cover a large area of the body, or exhibit signs of infection such as increased redness, swelling, or oozing of pus. You need immediate professional supervision in case your burn has gone above second degree and started to blister.

Place the burned body part into cold water to make yourself more comfortable and reduce the pain until you get medical help. Additionally, if the burn is on the face, hands, feet, or genitals, it is recommended to consult a healthcare professional for proper evaluation and treatment.

Can you get skin cancer from welding?

While it is true that UV light can increase the risk of developing skin cancer, the risk associated with welding is relatively tiny compared to other forms of skin cancer caused by factors such as sun exposure or tanning salon use.

Does sunscreen help prevent welding sunburns?

When considering sunscreens suitable for safeguarding against harmful UV radiation emitted by welding, understand that their effectiveness varies. It’s recommended to look for sunscreens containing the ingredient “zinc oxide,” offering superior protection against UVA and UVB rays.

A high SPF (Sun Protection Factor) rating, like SPF 45 or 50, would provide optimal protection against intense UV radiation during welding operations.

Here are two recommended sunscreens suitable for shielding from welding UV burns:

1. Coppertone Pure and Simple Zinc Oxide Mineral Sunscreen: This sunscreen is known for its broad-spectrum protection, is equipped with zinc oxide, and has an SPF rating 50+. It’s water-resistant, maintaining its effectiveness during welding tasks, even when sweating or in contact with water.|

2. Neutrogena Sheer Zinc Oxide Sunscreen: This sunscreen is perfect for demanding environments, combining zinc oxide with Vitamin E to keep the skin hydrated and safe. It comes with an SPF 50+ rating to defend against harmful UV rays, thus thwarting painful sunburns. This product is designed for sensitive skin. It’s water-resistant and free from dyes and parabens.

Conclusion

Welding burns are prevalent injuries within the welding industry, resulting from exposure to extreme heat, intense light, and electric currents during the welding process.

There’s a variety of welding burns that each bear unique characteristics and require specific treatment methods. Two of the most frequently occurring types are flash burns and skin burns, caused by heat. A comprehensive understanding of each burn type is essential to administer the correct treatment and facilitate an effective healing process.

Proper prevention of welding burns places considerable emphasis on the use of protective gear. Essential items include welding helmets equipped with suitable shade lenses, safety glasses, and heavy-duty clothing covering exposed skin. Moreover, the avoidance of tanning salons and diligent eye protection, through either safety goggles or a combination of safety glasses and a face shield, are highly recommended.

By understanding the different welding burns and executing vital precautionary measures, welders can minimize the risk of injury and promote a safe working environment.

Reference