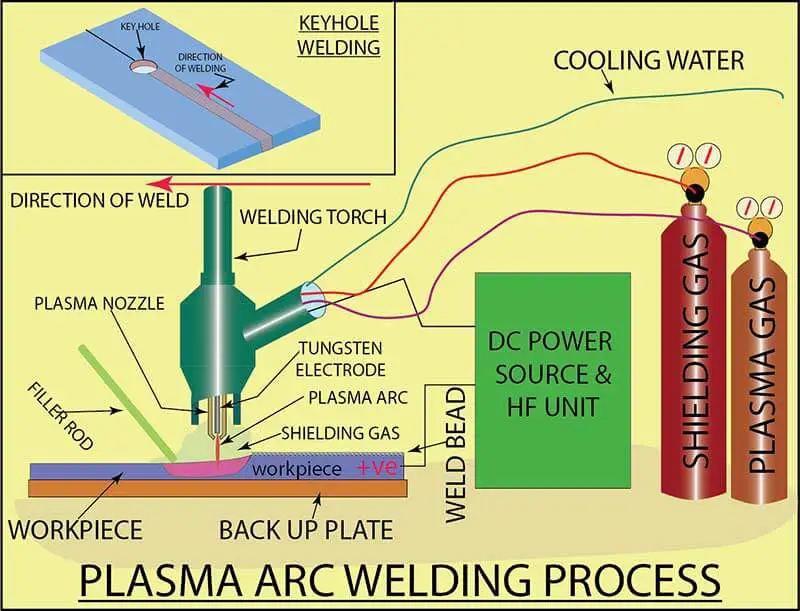

Plasma arc welding (PAW) is an arc welding process similar to gas tungsten arc welding (GTAW). The arc is formed between the electrode, usually made of sintered tungsten, and the copper nozzle or the workpiece. Unlike gas tungsten arc welding, the plasma arc welding electrode is positioned within the torch’s body; hence, the plasma arc is separated from the shielding gas envelope. The plasma is forced through a fine-bore copper nozzle, the nozzle constricts the arc, and the plasma exits the orifice at high velocities and a high temperature.

What is the principle of plasma arc welding, and how does it work?

You can say that the plasma arc welding (PAW) process is a progression of gas tungsten arc welding (GTAW) or TIG welding. However, the construction of the welding torch in PAW is very much different from that of GTAW. The water-cooled PAW torch has two nozzles:

- An inner copper nozzle with a small orifice with the non-consumable tungsten electrode positioned inside it. The inner nozzle (sometimes called plasma nozzle) has a supply of inert gas (argon or helium or a mixture of argon and helium).

- An outer nozzle (surrounding the inner nozzle) for the supply of shielding gas.

The welding arc can be struck between the tungsten electrode and the inner cooper nozzle or between the tungsten electrode and the workpiece. The arc is forced through the orifice of the inner copper nozzle. This causes constriction (narrowing) of the arc, reduces the cross-sectional area of the arc, and increases its energy density. This feature makes plasma arc welding “a process with low heat input and higher energy density.”

What is plasma, and how is a plasma formed in the plasma arc welding process?

We all know about the three states of matter, viz. solid, liquid, and gas (like ice, water, and steam). But what happens if you provide more heat to a gas? When you provide more thermal energy (say more than 5000ºC), the gas becomes ionized (electrically conductive), and such an ionized gas is called plasma. Some people refer to plasma as the fourth state of matter (the previous three states are solid, liquid, and gas). The arc in PAW can be formed between the tungsten electrode and the workpiece or between the tungsten electrode and the copper nozzle. An inert gas (argon or helium) is passed through the inner nozzle, and this inert gas gets heated by the welding arc and becomes ionized. This ionized gas is the plasma, and the narrow orifice of the inner nozzle through which it comes out makes the plasma constricting and high velocity.

The temperature of the plasma arc is very high compared to the arc in the GTAW process. The combination of high-velocity plasma and high temperature results in high energy density. The high energy density results in higher penetration and the ability to weld thicker metals at higher weld speeds. The flow of the plasma from the nozzle orifice is at high velocity, nearer to the speed of the sound. The plasma jet’s thermal energy and temperature depend on the electric power used and the flow rate of plasma gas. The temperature of the constricted plasma arc can be 28000ºC, which is very high compared to the 5500ºC of the ordinary welding arc or around 11000ºC in GTAW. All welding arcs are plasmas (partially ionized) to a small extent, but the plasma welding process forms a constricted plasma arc of high temperature and high thermal energy.

Plasma arc welding is a fusion welding process, and here the thermal energy of the constricted plasma arc is used for the melting and fusion of the faying surfaces. Inert gasses like argon or helium or a mixture of argon and helium are used as shielding gas for protecting the weld pool from atmospheric air and other contaminants. Usually, the gas used for forming the plasma and that used for shielding are the same.

Effect of the constriction of arc in plasma arc welding

- Fewer problems are associated with residual stress and heat-affected zone (HAZ).

- The constricted arc resulted in higher weld penetration and reduced weld bead width.

- The thermal energy in the plasma welding process depends on plasma current, size of the nozzle orifice, and plasma gas.

Similarities and differences between plasma arc welding (PAW) and GTAW (TIG)

There are similarities as well as dissimilarities between PAW and GTAW (TIG). The apparent similarity is that both the processes use a non-consumable tungsten electrode and inert gasses for shielding.

The major dissimilarity between PAW & GTAW is that GTAW uses the heat generated by the arc between a tungsten electrode and the workpiece for welding. In contrast, PAW uses the heat generated by the plasma arc between the tungsten electrode and the workpiece or between the tungsten electrode and the plasma nozzle for welding. Also, the energy density in PAW is more than GTAW.

READ: Insider’s Guide To Gas Tungsten Arc Welding (GTAW / TIG)

| No |

Plasma arc welding (PAW) |

Gas tungsten arc welding (GTAW) or TIG welding |

| Similarities | ||

| 1 | Both PAW and GTAW processes use a non-consumable electrode, normally tungsten. | |

| 2 | Both PAW and GTAW processes typically use an inert gas like argon or helium or a mixture of argon and helium as shielding gas. | |

| 3 | The method of using filler wire is the same in PAW and GTAW processes. | |

| Differences | ||

| 1 | The non-consumable tungsten electrode is positioned inside the inner copper nozzle of the welding torch and usually is not visible from the outside. | The non-consumable tungsten electrode is held in the torch and is visible. |

| 2 | The temperature of the constricted arc in plasma arc welding can reach a temperature as high as 20000ºC. | The typical tungsten arc in GTAW has an approximate temperature of 11000ºC.

|

| 3 | The PAW process uses the heat generated by the constricted plasma arc for welding. | The GTAW process uses the heat generated by the non-constricted arc for welding. |

| 4 | The thermal efficiency of PAW is much higher than GTAW due to the ionized plasma gas. | The thermal efficiency of GTAW is less than PAW. |

| 5 | PAW process has a higher penetration depth, higher speed of welding and low heat affected zone (HAZ) compared to GTAW. | GTAW has a low depth of penetration, lower welding speed, and high heat-affected zone (HAZ) compared to PAW. |

| 6 | PAW process gives out infrared and ultraviolet rays that are harmful to human beings. In addition to this, there is high noise of 100 DB. | While the GTAW process also gives out harmful infrared and ultraviolet rays that are harmful, there is no issue of high noise. |

| 7 | PAW process is adaptable for the keyhole method of welding. | GTAW process usually is not used for the keyhole method of welding. |

| 8 | PAW process uses inert gasses at two places; the first is the plasma gas, and the second is for shielding gas. | GTAW process uses inert gas as shielding gas only. |

| 9 | The cross-section (spread) of the constricted plasma arc is significantly less compared to the arc in GTAW, and hence the current density is very high. | The cross-section (spread) of the arc between the tungsten electrode and the workpiece is much more than the PAW process, and hence the current density is low. |

| 10 | The initial cost of PAW equipment is higher than GTAW. | The initial cost of GTAW equipment is lower than PAW. |

| 11 | The distortion of the workpiece in the PAW process is less than GTAW. | The distortion of the workpiece in the GTAW process is more than PAW. |

| 12 | The construction of the welding torch in the PAW process is complex. | The construction of the welding torch of the GTAW process is simple compared to PAW. |

| 13 | High skilled welder is required to operate PAW. | The skill level is comparatively low for GTAW. |

GTAW and PAW welding machine

You may be able to use your GTAW machine as a PAW machine by adding a plasma control console to the GTAW power source and changing the welding torch to a plasma welding torch. However, this method may not give all the flexibility and efficiency of regular plasma welding equipment.

Conclusion

Plasma arc welding is relatively new compared to other established welding processes, and its versatility is unknown to many people. However, PAW has many advantages over GTAW/TIG, and it will be adapted in more and more industries in the days to come.

References