A boat transom is an essential component of a boat’s structure, located at the stern (rear) of the vessel. The transom primarily strengthens your boat’s stern and aft sections. It serves several vital functions, making it a critical component of any boat.

A sturdy and well-maintained transom is essential for the overall strength and durability of the boat, as a damaged transom can compromise the entire boat’s structural integrity.

What Is The Transom Used For?

One of the primary uses of the transom is to provide a secure mounting point for various equipment, such as outboard motors and rudders. This allows for easy installation and removal of these essential components.

Additionally, the transom serves as a structural reinforcement for the stern and aft sections of the boat. However, many modern or offshore vessels sometimes include additional fixtures or devices on their transoms, such as consoles, rear doors, ladders, and so on.

It is typically made from reinforced fiberglass or other durable materials to ensure strength and durability. This is necessary to support the weight and torque generated by the outboard motor and any additional fixtures that may be mounted on it.

The transom is designed to withstand water pressure, vibrations, and other forces while the boat is in motion. It provides stability and balance, helping to maintain control and maneuverability.

Difference Between Stern, Transom, and Aft

In boating terms, it is essential to understand the difference between the stern, transom, and aft. While some sailors use these terms interchangeably, they refer to distinct components of a boat’s structure.

The stern refers to the entire rear of the boat, it is where the boat’s propulsion system is usually located, whether it’s an outboard motor, inboard motor, or even a sail. The stern also includes the aft deck and features like swim platforms or fishing amenities.

On the other hand, the aft is a general term used to describe the back portion of the boat. It encompasses both the stern and any other areas located towards the rear.

The transom is a specific vertical component that connects the two sides of the hull at the stern. The transom is where the outboard motor is typically attached and securely mounted to provide power for propulsion.

What Material is Used on Boat Transoms?

When choosing the material for your boat transom, consider the type of boat, its power rating, intended use, and your boating experience. Each material offers its advantages and considerations, so making an informed decision based on your specific needs is vital.

Let’s take a closer look at the common materials used for boat transoms:

1. Plywood

Marine-grade thick plywood is a popular choice for boat transoms. It comprises several thin layers of wood veneer bonded together with waterproof glue.

Marine plywood is known for its strength, stability, and resistance to rot and delamination. It can withstand the demanding marine environment but requires proper sealing and maintenance to keep it in optimal condition.

2. Fiberglass

Fiberglass transoms are created by laminating layers of fiberglass cloth and resin over a core material. These transoms offer excellent strength-to-weight ratio, corrosion resistance, and durability.

They are often reinforced with additional layers of fiberglass fabric for added structural integrity. Fiberglass transoms are commonly found in modern boats and are known for their long lifespan.

3. Aluminum

Aluminum transoms are lightweight and offer good strength and durability. They are commonly used in smaller boats and are resistant to corrosion.

Aluminum transoms can be welded or bolted onto the hull, providing a secure mounting point and ease of installation for various equipment.

Common Types of Boat Transoms

1. Flat Transom

As its name suggests, a flat transom is perfectly vertical and flat, forming a 90-degree angle with the boat’s hull. This is the most traditional and common type of transom found on many kinds of boats, ranging from small fishing craft to large yachts.

The flat transom is often favored for its simplicity and practicality. It provides a big and level surface for mounting outboard motors, which is especially beneficial for fishing and other workboats. It also adds significant stern buoyancy that can improve the boat’s stability, especially when the boat is stationary or moving at slower speeds.

Additionally, a flat transom offers abundant storage space in the aft part of the boat and can be a useful platform for various activities such as fishing or diving.

However, a flat transom also has some drawbacks. Its hard-angled and flat design can result in a rougher ride when the boat moves at higher speeds in choppy waters. It is less aerodynamic than other transoms and can produce more drag, leading to less efficient fuel consumption.

Also worth noting is that it doesn’t have the modern, sleek look that a reverse or cutaway transom offers, which might be an aesthetic drawback for some boaters.

2. Raked Transom

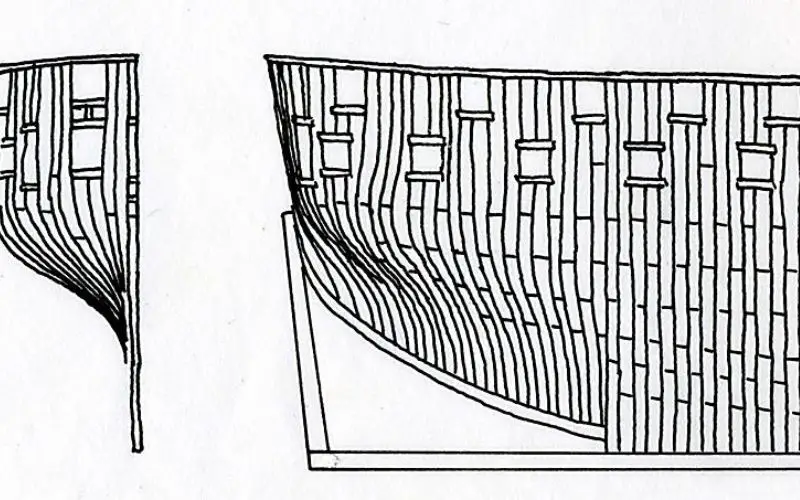

A raked transom, notably known for its characteristic angled or ‘raked’ design, is another form that veers from the traditional flat format and provides unique advantages. This transom type leans outward from the bottom to the top, offering an aesthetically pleasing classic boat profile often seen in older, more traditional boat designs.

A raked transom’s primary benefit is its additional buoyancy at the stern. The raked design puts more hull surfaces in the water when the boat is still or moving at slow speeds, thereby making the boat more stable.

In terms of disadvantages, the raked design can make it more challenging to mount accessories, such as outboard motors, owing to the angling of the surface. Additionally, the extra surface area of a raked transom may increase the hull’s wetted surface and thus potentially increase drag, theoretically leading to slower speeds and less efficient fuel consumption than boats with flat transoms.

3. Reverse Transom

A reverse transom is a distinct design feature found on modern boats that adds a touch of sophistication and style. Unlike traditional flat transoms that extend vertically from the hull, a reverse transom slopes or angles inward, creating a sleek and contemporary look.

It is often characterized by a curved or cutaway design that enhances the overall aesthetics of the vessel. It is commonly seen on various boats, from recreational pleasure crafts to high-performance offshore boats.

One of the key advantages of a reverse transom is its aerodynamic benefits. The inward slope reduces drag, allowing the boat to cut through the water more efficiently. This can result in improved fuel efficiency and higher speeds.

They also provide a convenient entry point from the water, making it easier for boaters to board and disembark. Reverse transoms also serve as attachment points for accessories like cleats, creating additional functionality and convenience for boat owners.

However, there are some potential disadvantages to consider. The inward slope of a reverse transom can affect the boat’s stability in certain conditions, particularly in rough waters. Additionally, the design may limit storage space in the rear of the boat, as the inward slope reduces the flat surface area.

4. Cutaway Transom (Elliptical)

Many sailboats come equipped with a unique feature known as a cutaway transom that provides significant benefits for sailors. This iteration involves eliminating a section of the transom, which results in a recessed or cutaway area at the boat’s stern.

The cutaway transom serves to enhance a sailboat’s performance. By means of the recessed area, it mitigates the drag produced by the stern against the water. This feature facilitates smoother and more efficient sailing experiences, particularly under light wind conditions. This creates a more enjoyable and efficient sailing experience for the sailor.

What is a Wet Transom?

A wet transom refers to a condition where water has infiltrated the core of a boat’s transom, leading to potential damage and structural issues. This can occur when the protective barrier, such as gelcoat or paint, on the transom’s exterior, becomes compromised, allowing water to penetrate the underlying layers.

Signs of a wet transom can include visible cracks in the gelcoat, visual movement or flexing of the transom, and even water spitting out of the hull when pressure is applied. These indicators suggest that moisture has seeped into the transom, potentially causing damage and rot over time.

To prevent a wet transom, it is crucial to regularly inspect and maintain it, ensure that all seams and hardware are properly sealed, and promptly address any cracks or damage to the gelcoat or paint.

How to Examine and Repair a Boat Transom

To begin the examination process, start by checking the surface of the transom for any visible cracks or signs of damage. Surface cracks can occur due to stress, impacts, or age and can indicate more profound issues. If surface cracks are present, inspecting the transom’s plywood core is crucial.

This can be done by drilling small core samples to determine the extent of the damage. The core must be repaired or replaced if it is wet or rotten.

Repair options for a damaged transom will vary depending on the severity of the damage. Applying a high-quality marine-grade sealant for surface cracks can help prevent further moisture penetration and reinforce the transom’s structure.

If the core is compromised, replacing the entire transom with marine-grade plywood may be necessary for maximum strength and durability.

By promptly addressing any issues and using quality materials, you can ensure that your boat’s transom remains in excellent condition for years.

Can a Transom Get Damaged?

Yes, a boat transom can get damaged due to various factors. Let’s explore the types of damage that can occur to a boat transom and their potential causes.

Mechanical damage

This is a common source of transom damage, often caused by running aground or hitting debris in the water. These incidents can lead to cracks, fractures, or even structural failure in the transom. The consequences of mechanical damage can range from compromised structural integrity to water leaks, risking the boat’s and its occupants’ safety.

Water damage

Prolonged exposure to water can cause cracks or loose sealing, allowing water to seep into the transom. This can lead to rot, especially if the transom is made of wood or contains a wooden core. Rot weakens the transom, making it unable to support the weight of the motor or causing the transom to flex, leading to further damage.

Do All Boats Have Transoms?

Modern boats are typically designed with the intent that a motor will be attached to the transom. While most modern boats have a transom, this rule has some exceptions. For example, vessels with a canoe stern do not have a traditional transom.

A canoe stern is a design feature where the stern of the boat slopes upwards from the waterline, resembling the shape of a canoe. This design choice is often seen in smaller sailboats and adds to their aesthetic appeal.

Do All Boats Have the Same Transom Size?

Regarding boat transoms, one size certainly does not fit all. The dimensions of a boat’s transom can vary greatly depending on factors such as the size of the boat, the power rating of the outboard motors, and the style of the transom.

In general, larger boats tend to have larger transoms to accommodate their engines’ increased weight and power. Similarly, boats with higher power ratings require larger transoms to provide stability and support. On the other hand, smaller vessels may have smaller transoms to maintain balance and maneuverability.

The style of the transom also plays a role in determining its dimensions. Different types of transoms can be seen on boats, including square, round, and raked transoms. Each style serves a specific purpose and can affect the overall dimensions of the transom.

Conclusion

Boat transoms are essential components of a boat that ensure safety, stability, and overall performance. Transoms are built to withstand harsh sea conditions and heavyweights that boats carry.

When selecting a transom, it is essential to consider several factors, such as the boat size, weight, and intended use. The material used in building the transom should also be carefully chosen to reduce the risk of rot or corrosion over time.

Overall, boat transoms are investments that every boat owner should seriously consider to ensure their safety and that of their passengers.

References: