Excellent welding electrodes brands are available on the market, delivering welding rods that give enjoyment and fulfill the desires of welding hobbyists.

Many newbies or even professional welders ask, which is the best welding rod? Which welding electrodes brand is the best? What is the welding rod that fits the purpose? It all depends on the material you intend to weld and your project requirements.

Various parameters have to be considered during welding rod selection; the welding rod has to match the base metal’s mechanical properties and chemical composition. Besides, joint geometry, welding position, cost, and operational condition are also considered during the selection process.

Although thousands of stick welding electrodes exist, E6010, E6011, E6013, E76014, E7018, and E7018AC are the most common electrodes in use.

When you browse online for welding rods, you may be overwhelmed by the varieties, brands, and range of prices available. Different types of welding electrodes are available based on the requirements and the condition of the welding job.

It is essential for you as a welder to select the best-suited welding rod for your specific project requirements to get the best result out of your welding. So, let us take a look at our following best stick welding rods on the market. We will try to help you make a wise decision while buying your next project welding rods.

Best Stick Welding Rods for Mild Steel in 2026

- Forney E6010 Welding Rod (Best welding rod for light/medium dirt, rust, or paint)

- Forney E6011 Welding Rod (Best welding rod for Rusty Metal)

- Forney E6013 Welding Rod (Best welding rod for Thin Metal)

- Forney E7014 Welding Rod (Best DC welding rod)

- Forney E7018 Welding Rod (Best welding rod for Beginners)

- Forney E7018AC Welding Rod (Best welding rod for Hardened Steel)

Best Welding Rod for Welding on Light/Medium Dirt, Rust, or Paint

Forney E6010 Welding Rod

E6010 welding rod deposits molten metal, which solidifies rapidly; therefore, the electrode is categorized as a fast freezing electrode. As the welds tend to solidify fast, the electrode requires a skilled welder to produce a sound weld.

E6010 electrode is a general-purpose electrode that performs welding in all positions and efficiently in vertical-up and over-head positions; however, the electrode deposition rate is not high. The electrode arc is easy to control and produces a flat weld bead with a light slag formation.

The advantage of the E6010 electrode is that it produces deep penetration welding and can be used on painted, galvanized, and unclean surfaces.

Key features of Forney E6010 Welding Rod

- Recommended polarity: DCEP (Reverse Polarity).

- Available diameters: 1/8″.

- Tensile Strength: 60,000 PSI.

- All position welding rod with digging arc, the rod performs welding on dirty, rusty, and painted metals.

- The rod is ideal for joints requiring deep penetration.

- The rod produces good welds on vertical and overhead welding with light slag.

- Minimal surface preparation is required.

- Excellent for welding on galvanized steel and contaminated steel.

- Ideal for maintenance or general repairs works and the root pass of pipe welding.

Best Welding Rod for Rusty Metal

Forney E6011 Welding Rod

E6011 electrode is also categorized as a fast freezing electrode. E6011 electrode is a general-purpose electrode that performs welding in all positions and efficiently in vertical-up and over-head positions; it is used mainly for sheet metal welding and low silicon deposit application.

The electrode arc is easy to control and produces a flat weld bead with a light slag formation.

E6011 can be used with either AC or DC current. The electrode produces deep penetration welding and can be used on painted, galvanized, and unclean surfaces.

Key features of Forney E6011 Welding Rod

- Recommended polarity: AC or DCEP (Reverse Polarity).

- Available diameters: 3/32″, 1/8″, 5/32″.

- Tensile Strength: 60,000 PSI.

- The electrode is easy to use.

- Provides fast travel speeds.

- All position welding, all-purpose rod for deep penetration and fast freezing.

- The rod performs welding on dirty, rusty, and painted materials.

- Smooth arc wetting and spread with low spatter.

- The rod produces fast deposition and flatter contour fillets.

- Minimal surface preparation is required.

- Excellent for welding on galvanized steel and contaminated steel.

- Ideal for maintenance or general repairs works.

Best Welding Rod for Thin Metal

Forney E6013 Welding Rod

E6013 welding rod provides a fast freeze and fast fill characteristic; therefore, the electrode is categorized as a fill-freezing electrode.

The electrode is a general-purpose electrode that performs welding in all positions with medium deposition rate and medium penetration.

E6013 electrode is used for sheet metal welding and other low current applications. The electrode is easy to use and produces good appearance welds with minimal spatter.

Key features of Forney E6013 Welding Rod

- Recommended polarity: AC, DCEP, or DCEN.

- Available diameters: 5/64″, 3/32″, 1/8″, 5/32″.

- Tensile Strength: 60,000 PSI.

- The electrode is easy to use.

- All position welding, all-purpose rod for shallow penetration, ideal for vertical down welding.

- Ideal for poor fit-up joints.

- The rod has excellent wetting action, providing smooth and flat beads.

- Low spatter and excellent slag removal.

- Use on all types of mild steel where a good appearance is required.

Best DC Welding Rod

Forney E7014 Welding Rod

E7014 is a high-speed iron powder type electrode; the electrode is categorized as a fill-freezing electrode. The ease to use and the excellent weld characteristics make this electrode one of the most popular rods on the market.

The rod has smooth and stable arc characteristics, can be used in all positions, produces low spatter and medium to low penetration.

E7014 produces smooth beads appearance and offers outstanding thick, easy-to-remove slag. This electrode is suitable for high deposition and fast welding.

Key features of Forney E7014 Welding Rod

- Recommended polarity: AC, DCEP, or DCEN.

- Available diameters: 3/32″, 1/8″, 5/32″.

- Tensile Strength: 70,000 PSI.

- All position welding rod with digging arc for deep penetration.

- The rod performs welding on dirty, rusty, and painted materials.

- The rod is ideal for joints requiring deep penetration.

- The rod produces good welds on vertical and overhead welding with light slag.

- Minimal surface preparation is required.

- Excellent for welding on galvanized steel and contaminated steel.

- Ideal for maintenance or general repairs works, plus pipe welding.

Best Welding Rod for Beginners

Forney E7018 Welding Rod

E7018 is a low hydrogen electrode; the electrode is used with metal that tends to crack and thick sections. The electrode produces weld with excellent toughness and high ductility and reduces the risk of hydrogen embrittlement cracking when welding thick sections.

E7018 produces excellent quality welds with steel requiring a strength of 70,000 PSI and above; the electrode can be used with medium carbon, high carbon, and low-alloy steel.

One of the essential points to consider for E7018 is the storage and drying procedure; the electrode must remain in a low humidity environment to minimize the moisture in the electrode coating to reduce hydrogen level and avoid hydrogen cracking.

Key features of Forney E7018 Welding Rod

- Recommended polarity: AC or DCEP (Reverse Polarity).

- Available diameters: 3/32″, 1/8″, 5/32″.

- Tensile Strength: 70,000 PSI.

- The electrode is easy to use.

- All position welding, low hydrogen rod for general purpose.

- Ideal for hard-to-weld steels, including thick sections and restrained joints with cracking issues.

- Excellent for tack welds and out-of-position welding.

- Ideal for general fabrication of cold roll steels.

Best Welding Rod for Hardened Steel

Forney E7018AC Welding Rod

E7018AC is a low hydrogen, iron powder type electrode; the electrode is used for welding hardenable-steels with no preheat and for cold roll steels exhibiting excessive porosity when welding with conventional electrodes.

The electrode is designed for all position welding; the electrode is a version of E7018 specifically designed to have optimum characteristics when used with an AC power source.

E7018AC is much easier to strike, has a highly stable arc, and runs smoother than conventional 7018 electrodes which do not run well on older 180 & 225 amp machines. E7018AC welds exceptionally well on small-type with low open circuit-Voltage (OCV) welders.

Key features of Forney E7018AC Welding Rod

- Recommended polarity: AC or DCEP (Reverse Polarity).

- Available diameters: 3/32″, 1/8″, 5/32″.

- Tensile Strength: 70,000 PSI.

- The electrode is easy to use.

- All position welding, low hydrogen rod for general purpose.

- The electrode offers easy re-striking.

- Excellent bead contour, light spatter, and slag is often self-cleaning.

- Good performance with low open circuit-Voltage (OCV) power sources.

- Excellent for tack welds, skip welds, and out-of-position welding.

- Ideal for shops, farms, hobbyists, and DIY welders.

Welding Electrodes Buying Guide

Stick welding electrodes can be operated with AC or DC sources, and all the AC electrodes may be used on AC or DC; however, all the electrodes meant for DC may not be adaptable to AC.

The electrode selection for the stick welding depends mainly on the material of the workpiece, required weld properties, and welding position (flat, slant, vertical, overhead, etc.).

The metal electrode has a flux coating, which burns along with the electrode, and gives gases to protect the arc and the molten weld pool from oxidation and contamination. Further, the flux coating purifies the weld, improves the weld quality by providing alloying elements, and creates a protective slag on the weld bead, which can be chipped off later.

How to select the best welding rod?

Strength comes first; while selecting the proper electrode, the electrode’s mechanical properties and chemical composition have to match the base metal.

Joint design and position are essential in the selection of the rod. Power source availability is another factor to consider; some electrodes can be used with AC or DC, while others used with either AC or DC.

When deep penetration is required for the root pass, E6010 or E6011 will be selected to provide welding with sufficient penetration. However, when the joint is wide root openings or thin material, the option will be E6013.

For welding thick sections, or for application where toughness and high ductility joint is demanded or where the development of embrittlement cracking is an issue, E7018 is usually the proper selection.

When welding hardened steels with no preheat and for cold roll steels exhibiting excessive porosity, E7018AC is the option that offers easier strike, extremely stable arc, and smoother running than conventional E7018 electrodes.

What current and polarity to use with the welding rod?

The current operating level depends on the size of the electrodes, and usually, the recommended operating range of current will be mentioned on the electrodes box.

The general thumb rule is 40 Amps per mm diameter, and hence the current requirement for a 3 mm diameter welding electrode could be 120 Amps. Still, the electrode manufacturers may mention a range like 100 to 140 Amps.

The direct current electrode negative (DCEN) method causes building up of the heat in the electrode, higher rate of electrode melting, and lesser depth of the weld. The direct current electrode positive (DCEP) method causes an increase in weld penetration. When alternating current (AC) is used, it gives a heat distribution that balances the electrode melting rate and penetration.

What is the meaning of welding rod deposition rate?

The deposition rate of welding electrodes is the rate that molten metal from weld can be deposited expressed in grams, kilograms, or pounds per hour.

The calculation is based on continuous operation, excluding the stoppage time consumed while inserting a new electrode, cleaning slag, or other external reasons.

What is the size of the welding rod?

Electrode diameter and length have to meet the order requirements, typically 350-450mm length and 2.5-6mm electrode diameter; however, other lengths and diameters are available.

What is the purpose of welding rods flux coating?

The flux coating contains metallic and non-metallic components added to enhance the weld joint’s specific properties. The flux coating plays a vital role in arc stabilization and provides the following benefits:

- Produces shielding gas which protects the welding arc and molten metal from contamination by air.

- Produce slag, which protects the weld metal.

- Control hydrogen content.

- Refine weld metal.

- Add necessary alloying elements based on the welding application requirements.

- Helps in arc ignition.

For instance, manganese is added to the flux coating to improve the weld metal’s toughness and strength; besides, silicon is added as a deoxidizing element that Interacts with the molten metal and forms oxide silica that removes oxygen from weld metal.

A metal powder is added to welding electrodes producing what we call Metal Powder Electrodes. Metal Powder Electrodes can handle higher welding current levels. Therefore, it gives a higher metal deposition rate (up to 140%) compared with an electrode containing no iron powder.

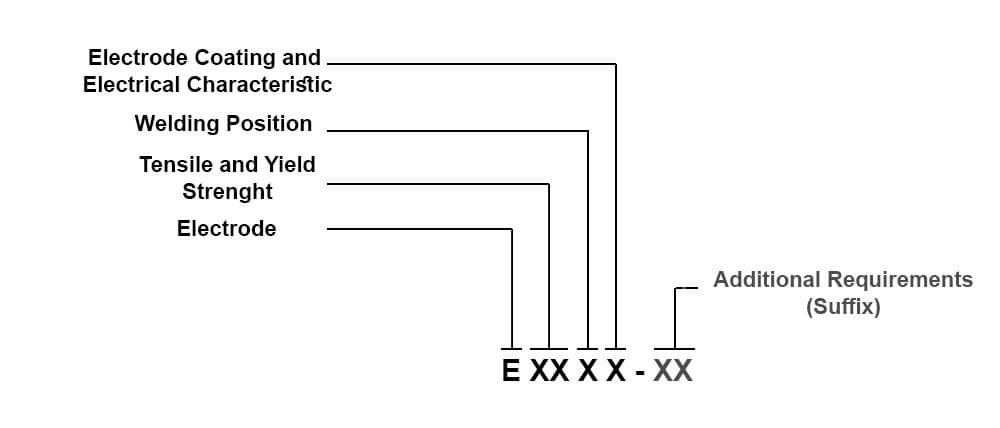

Welding Electrodes Identification (Classification)

What is the meaning of the number on the welding rods?

AWS A5.1 and A5.5 Standards classify carbon steel electrodes and low-alloy steel electrodes for shielded metal arc welding. The electrode’s designation is divided into mandatory and supplementary; both mandatory and supplementary designators have to be printed on each electrode as per classification system requirements.

Each digit of the electrode designation is used to designate a specific requirement of the standard as follow:

E – Electrode

Tensile and Yield Strength – in PSI of the weld metal

- E60xx – Tensile Strength of 60,000 psi

- E70xx – Tensile Strength of 70,000 psi

- E80xx – Tensile Strength of 80,000 psi

- E90xx – Tensile Strength of 90,000 psi

- E100xx – Tensile Strength of 100,000 psi

- E110xx – Tensile Strength of 110,000 psi

- E120xx – Tensile Strength of 120,000 psi

Welding Positions

- Exx1x Flat, Horizontal, Vertical (up), Overhead.

- Exx2x Flat, Horizontal.

- Exx3x Flat.

- Exx4x Flat, Horizontal, Overhead, Vertical (down).

Electrode Coating

- Exxx0 – Cellulose, Sodium

- Exxx1 – Cellulose, Potassium

- Exxx2 – Rutile, Sodium

- Exxx3 – Rutile, Potassium

- Exxx4 – Rutile, Iron Powder

- Exxx5 – Low Hydrogen, Sodium

- Exxx6 – Low Hydrogen, Potassium

- Exxx7 – Iron Powder, Iron Oxide

- Exxx8 – Low Hydrogen, Iron Powder

- Exxx9 – Iron Oxide, Rutile, Potassium

Electrode Current and Penetration

- Exxx0 – DC+ (Deep Penetration)

- Exxx1 – AC/DC+ (Deep Penetration)

- Exxx2 – AC/DC- (Medium Penetration)

- Exxx3 – AC/DC+/DC- (Light Penetration)

- Exxx4 – AC/DC+/DC- (Medium Penetration)

- Exxx5 – DC+ (Medium Penetration)

- Exxx6 – AC/DC+ (Medium Penetration)

- Exxx7 – AC/DC- (Medium Penetration)

- Exxx8 – AC/DC+ (Medium Penetration)

- Exxx9 – AC/DC+/DC- (Medium Penetration)

Additional Requirements as per AWS A5.1

- (1) – Means increased toughness for E7018 electrodes or improved ductility for E7024 electrodes.

- (M) – Means electrode meets most military requirements; military requirements are usually greater toughness, lower moisture content, and specific diffusible hydrogen limits for weld metal.

- (H4), (H8), or (H16) – Indicates the maximum diffusible hydrogen limit measured in millimeters per 100 grams (mL/100g).

- H4 means 4mL per 100 grams.

- H8 means 8mL per 100 grams.

- H16 means 16mL per 100 grams.

Additional Requirements as per AWS A5.5

- (A1) – Steel Alloy Type: Carbon-Molybdenum.

- (B1) / (B2) / (B2L) / (B3) / (B3L) / (B4L) / (B5) / (B6) / (B8) – Steel Alloy Type: Chromium-Molybdenum with different percent.

- (C1) / (C1L) / (C2) / (C2L) / (C3) – Steel Alloy Type: Nickel Steel with different percent.

- (NM) – Steel Alloy Type: Nickel-Molybdenum.

- (D1) / (D2) / (D3) – Steel Alloy Type: Manganese-Molybdenum.

- (W) – Weathering steel.

- (G) – No required chemistry.

- (M) – Military-grade.

Our final verdict

In this article, we have tried to give a complete review of the best mild steel welding electrodes for different uses and applications to aid you in making the best purchase choice.

During your selection of welding rods, you need to choose considering high-quality performance and productivity. Besides, you also must be sure that the rod is compatible with your base metal, joint configuration, and other project requirements.

Though there are many different welding rods brands in the market, we believe Forney Industries electrodes are the best in quality and value on the market.

Either way, we believe that we put together the top quality and best-priced welding rods on the market that make hobbyists and beginners keep on their welding and fabrication journey.