A great tungsten welding electrode is essential for professional looking weld bead with TIG welding. Tungsten electrode grinding using electrode sharpener, grinder, or other methods is the key factor affecting arc starting, weld penetration, arc shape, and electrode life.

The selection of the right type and good quality tungsten electrode is not the only factors influencing the appearance of the welding. Grinding and sharpening the tungsten electrode has a major role as well in having an excellent weld bead.

If the tungsten electrode is not sharpened correctly, you could face many issues during welding ending up with an unclean and weak weldment. Therefore, for the best performance of TIG welding, the tungsten electrode is usually sharpened properly before welding starts.

It is essential for you, as a TIG welder, to know how to grind your tungsten electrodes correctly to get the best result out of your welding. You may equip yourself with the proper grinders and sharpening tools to make your life easier.

So, let us look at how to sharpen tungsten electrodes properly and what tools we recommend for every method so you can unfold the full effect of tungsten electrodes.

Best Tungsten Electrode Sharpeners in 2026

• Tungsten Electrode Grinder Turbo-Sharp X (Best Tungsten Sharpener for Professionals)

• Sharpie DX Deluxe Tungsten Grinder (Runner Up 1)

• Eastwood TG1800 TIG Welder Tungsten Grinder (Best Affordable Tungsten Sharpener)

• Magneto Aluminum Sharpener/Grinder Head Tool (Best Tungsten Electrode Grinding Head Tool)

• DEWALT Bench Grinder, 8-Inch (DW758) (Best Bench Grinder)

• MILWAUKEE’S M18 Cordless Grinder (Best Angle Grinder)

• Dynaflux Tungsten Electrode Sharpener (Best Chemical Sharpener)

The shape of the tungsten electrode tip

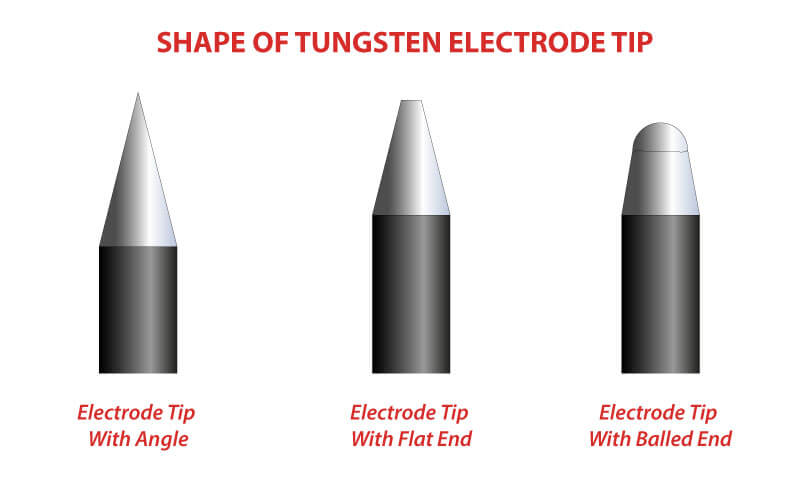

With DCEN (Electrode Negative) welding, you need to sharpen the tungsten electrodes to a specific angle. As a general rule, the length of the angle of the electrode tip is equal to approximately 2 to 2.5 times the electrode diameter.

Some welders prefer to ground flat the electrode tip to minimize the risk of the tip breaking off when initiating the arc or during welding.

With AC welding, you need to create balled shape of the tungsten electrode tip. To produce a ‘balled’ end, an arc initiated with the electrode connected to the positive side of the welder, the current increased until it melts the tip of the electrode.

When beveling the electrode tip, the desired end shape is obtained by grinding or using chemical compounds.

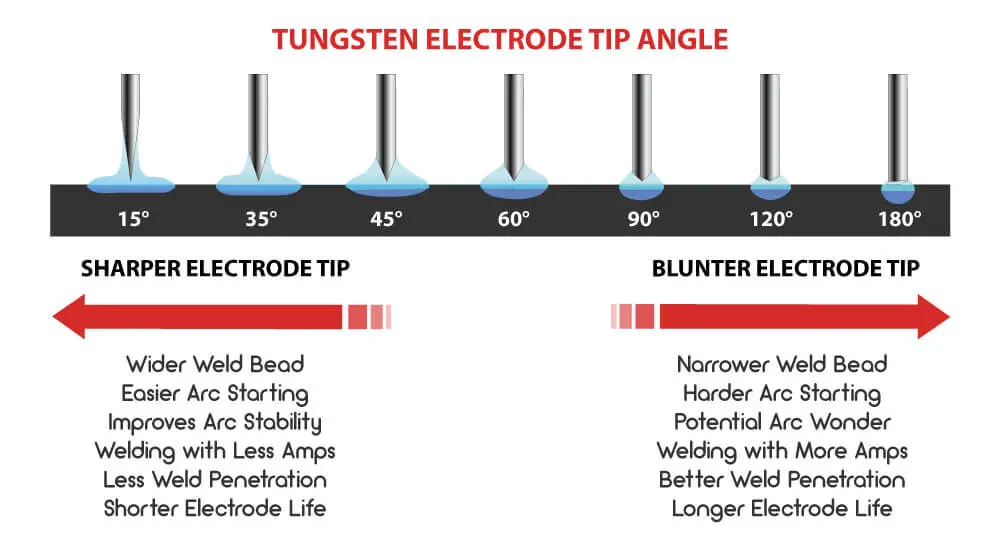

The angle degree is essential, and it is always recommended to follow the welding machine manufacturer’s suggested angle for optimal use of the welder. If the angle is not specified in your welder manual, you should optimize the tip angle to your particular welding operations.

Sharp electrodes (small included angle) produce wider weld bead, easier arc starting, consistent arc, less weld penetration, and using less welding current.

Blunt electrodes (large included angle) produce narrower weld bead, harder arc starting, may create arc wondering, better weld penetration, can handle more current without eroding, and last longer.

Tungsten electrode sharpening tools

Several sharpening and grinding tools are available on the market that performs tungsten electrode sharpening. Each tool has its benefits and drawbacks that you need to consider before you make your choice.

The sharpening tools can be categorized as follow:

- Specialized Tungsten Electrode Sharpeners.

- Sharpener/Grinder Head Tools.

- Bench / Angle Grinders.

- Chemical Tungsten Electrode Sharpeners.

Specialized Tungsten Electrode Sharpeners

Many specialized tungsten electrode sharpener brands are available on the market. Either they come as a hand-held tool that is inexpensive but with limited adjustment capabilities or as an industrial sharpener. The industrial tungsten sharpeners are offering many options and adjustment capabilities; however, they are more expensive and usually not affordable for general users.

The sharpeners come with slots or holes, normally sized 040″ all the way to 5/32″. The slots properly align the tungsten electrode with the grinding disc to produce the required finishes. Using these sharpeners is pretty easy. You need to pop the rod in, press the start button, and grind to the required level.

Best Tungsten Sharpener for Professionals

Tungsten Electrode Grinder Turbo-Sharp X

TURBO-SHARP X is a dedicated tungsten electrode grinder, which significantly reduces harmful radioactive (2%Thoriated) grinding dust exposure to both the user and the environment.

The sharpener reduces tungsten shedding, which increases electrode life; the grind finish of this tool improves welding arc starting and enhances welding consistency and stability.

TURBO-SHARP X features an adjustable head, 3 position adjustment allowing for grinding on a different area of the grinding disc, and triples the lifetime of the grinding disc.

Key features of Turbo-Sharp X

- Adjustable grind angles from 20-60 degrees.

- Minimizes grinding dust exposure.

- Fully enclosed grind head with a vacuum attachment to avoid dust exposure.

- Grind tungsten diameters .040 (1.0mm), 1/16″ (1.6mm), 3/32″ (2.4mm) & 1/8″ (3.2mm).

- Vise mounting bracket for easy and effective use.

- Electrode holder for grinding tungsten as short as 1.5″. (38.1mm).

- Meets strict safety requirements, including EN 50144, EN 55014, EN 61000, and more.

Pros

• Professional-grade grinder.

• Wide range of adjustable angle degrees.

• Extreme accuracy grind finish.

• High-quality product with a robust engineered motor.

• Portable enclosed tungsten grinder.

• Eliminates bench grinder contamination.

• 2-year product warranty.

Cons

• Costlier for beginners.

• A bit large for a hand-held unit.

• No electrode cut-off capability.

Runner Up 1

Sharpie DX Deluxe Tungsten Grinder

Sharpie DX Deluxe tungsten grinder is another dedicated highest-quality tungsten grinder on the market. The grinder lowers tungsten usage and improve grinding process safety.

The industrial-grade diamond wheel grinds tungsten electrode sizes of .040″, 1/16″, 3/32″ and 1/8″. The double-sided diamond grinding wheel delivers consistent grinds every time and lowers tungsten waste.

The sharpener cuts the tungsten electrode to the required length without bending it, preventing tungsten from splintering and avoid reducing electrode performance.

Key features of Sharpie DX Deluxe

- Adjustable grind angles from 15-45 degrees.

- Grind tungsten diameters .040 (1.0mm), 1/16″ (1.6mm), 3/32″ (2.4mm) & 1/8″ (3.2mm).

- Double-sided diamond grinding wheel for consistent grinds and low replacement part costs.

- Tip Flat function improves weld quality and extends tip life by grinding a “Flat” or “Land” on the electrode.

- The built-in cut-off option allows you to grind off contaminated portions of the electrode.

- Cuts tungsten electrode without bending it.

- The majority of machined parts are made in the USA, and each machine is built by hand.

- The enclosed grinding wheel eliminates safety issues.

Pros

• Works on 110V power supply.

• Double-sided grinding wheel.

• Cut-off/Score Option.

• Wide range of adjustable angle degrees.

• Fits multiple-sized tungsten.

• Portable enclosed tungsten grinder.

• Eliminates grinder contamination.

• Lowering tungsten waste and reducing costs.

Cons

• Expensive compared to the offered features.

• The instructions manual for adjustment is not clearly written.

Best Affordable Tungsten Sharpener

Eastwood Tungsten Grinder TG1800

Eastwood TG1800 tungsten grinder is a small handheld unit designed to hold both 1/16” and 3/32” tungsten at the exact 10 or 22.5-degree angle for re-sharpening, assuring the perfect point every time.

This Eastwood Tungsten Grinder features a long-lasting, double-sided Diamond Grinding Wheel that provides over 200 tungsten sharpening before requiring replacement.

It is fitted with a high-speed electric motor, allowing it to produce a finely sharpened point in the ideal 10° or 22.5° preferred angle within seconds for both 1/16” and 3/32” diameter tungsten electrodes.

Key features of Eastwood TG1800 Tungsten Grinder

- Works with all tungsten types.

- Works with 1/16” and 3/32” tungsten.

- Adjustable grind angles of 10 and 22.5 degrees.

- Double-sided diamond grinding wheel for low replacement part costs.

- Sharpen over 200 tungsten (100 on each side).

- New and improved unit with more power and less vibration.

Pros

• Small handheld unit.

• Plugs into a 120V power supply.

• Double-sided diamond grinding wheel.

• Designed to create the optimum rpm for the diamond sharpening wheel.

• Comes with 1-year warranty.

Cons

• Works on limited grind angles and rod diameters.

• No electrode cut-off capability.

Sharpener/Grinder Head Tools

The sharpener/grinder head tools are attachments for rotary tools that sharpen tungsten electrodes. These attachments are less expensive than the dedicated sharpeners; however, they require rotary tools to use them.

You need to verify that the head tool can attach to your rotary tool before buying it. If you do not have a rotary tool or suitable rotary tool in your workshop, you may need to consider the prices of the head tool and the rotary tool together and compare with other specialized tungsten electrode sharpeners before you make your choice.

Best Tungsten Grinding Head Tool

Magneto Aluminum Sharpener/Grinder Head Tool

Magneto special aluminum tungsten electrode sharpener/grinder head tool features flexible adjustment sharpening angle 0° – 180° and 6 adapters for any electrodes.

This sharpener head is manufactured of the highest quality aluminum alloy; gray anodizing coating ensures anti-corrosive protection for the head tool and makes it look presentable.

Special patented design compatible with all rotary tools with a 3/4-12 thread including Black and Decker, Milwaukee, Bosch, Dremel, and More.

Key features of Magneto Sharpener Head Tool

- Special design compatible with almost all rotary tools with a 3/4-12 thread (3/4″ and 12 turns per inch), including Black and Decker, Milwaukee, Bosch, and More.

- Allows sharpening electrodes at any angle (0° – 180°).

- The Head Tool includes 6 special stick adapters, suitable for all the most popular electrode diameters: .040″, 1/16″, 5/64″, 3/32″, 1/8”, and 3/32″.

Pros

• Compatible with almost all rotary tools.

• Manufactured of high-quality aluminum.

• A versatile tool provides the most flexibility in grinding tungsten electrodes in terms of angles and diameters.

Cons

• Need a rotary tool to operate.

Bench / Angle Grinders

A bench or angle grinder is the most common tool used to sharpen tungsten electrodes. The grinder used to sharpen tungsten should be clean, having a fine, hard stone, and use for grinding tungsten only.

A coarse grinding stone may increase tungsten breakage and gives poor grind finish, affecting the welding arc’s stability. If the grinder is used with other metals than tungsten, particles of these metals trap on the tungsten and break free when the arc is started, resulting in weld contamination.

Light pressure should be applied against the grinding wheel during grinding to reduce the risk of accidentally breaking the tungsten.

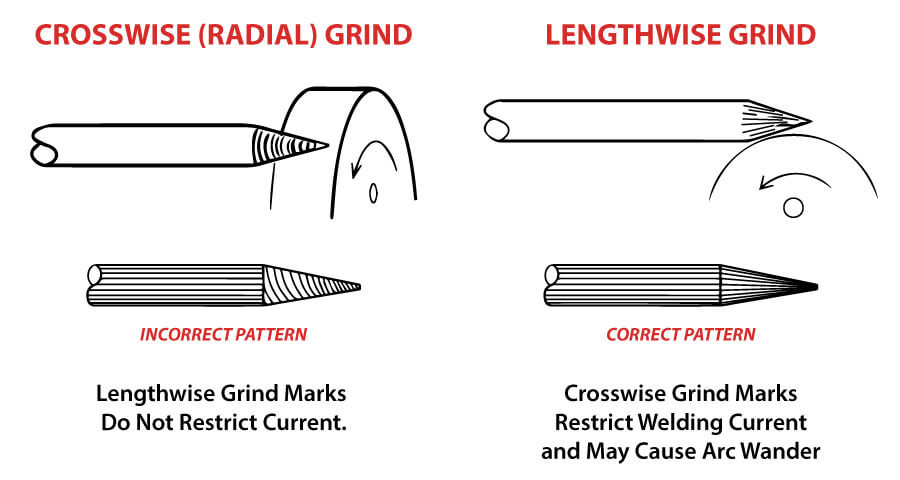

The most important point to remember during grinding is to grind the tungsten lengthwise. Lengthwise grinding reduces the tungsten contaminating the weld and creates a pattern on the rod that does not strict the current.

Another way to grind tungsten is to use an angle grinder; however, angle grinders are not the ideal way to do so.

The risk of contaminating the tungsten rod comes when using an angle grinder because of the variety of tasks we normally use the grinder for.

Apart from contamination, it is hard to get a consistent grind angle and finish with the angle grinder. Hence, the angle grinder should be your last option and when you do not have any alternatives.

Best Bench Grinder

DEWALT Bench Grinder, 8-Inch (DW758)

DEWALT DW758 is a heavy-duty 8-inch bench grinder that can be used in grinding operations, besides tungsten electrodes sharpening.

Powered by a 3/4 horsepower induction motor that runs at 3,600 RPM for easy and reliable high-speed material removal and fine sharpening results.

The DW758 is complemented by an industrial cast iron base and motor housing for added durability and prolonged life.

Key features of DEWALT DW758

- 8-inch bench grinder.

- 3/4 HP induction motor provides superior power.

- Designed for industrial grinding applications.

- Rugged cast iron base and motor housing provide durability and prolonged life.

- Motor runs at 3,600 rpm for high-speed material removal.

- Precision-machined aluminum tool rests allow the user to position work accurately.

- Rear exhaust ports in wheel guards for smoother operation.

- 12-1/2-inch distance between wheels for larger and longer grinding applications.

Pros

• Powerful grinder with the ability to shape steel tools.

• Designed for industrial grinding applications.

• Affordable and give the best value for the money.

• Superior power motor with high rpm for smooth grinding or metal removal.

• Tool rests allow the user to position works accurately.

• Durability and well made.

• 3-year limited warranty and one-year free service.

Cons

• Needs proper mounting to avoid vibration.

• Do not come with LED lights.

• A bit difficult to renew the grinding wheel as the shaft rotates and there is no locking feature.

Best Angle Grinder

Milwaukee Angle Grinder M18 Cordless

Milwaukee M18 is the highest quality power grinder on the market for industrial applications. The grinder provides speed, durability, and ease of use to the industrial user.

The girder comes with a Milwaukee 4-pole motor, delivering maximum power when cutting or grinding. The grinder has L-shape intake vents that protect the grinder by keeping harmful debris from entering the tool and damaging internal components.

Milwaukee M18 features Redlink Intelligence, which avoids wearing the motor down by Intelligently connecting the tool and the M18 battery charging it.

Key features of Milwaukee Angle Grinder M18 Cordless

- The paddle switch design makes the grinder activation easy.

- “L” shape molding near the grinding wheel picks up debris and prevents it from clogging up the tool.

- The grinder guard can be adjusted by pushing a button for different cutting angles and various applications.

- This Milwaukee power tool works with M18 18v lithium-ion Milwaukee batteries.

- Compatible with different models including 48-11-1860, 48-11-1850, 48-11-1828, and 48-11-1815, 48-11-1840, 48-11-1820.

- 4-pole motor delivers maximum power when cutting or grinding.

- Overload protection prevents damage to the tool and battery.

Pros

• The guard is easily adjustable.

• Affordable and give the best value for the money.

• 3-position side handle.

• 4-pole motor delivers maximum power.

• Works with M18 18v lithium-ion Milwaukee batteries.

• The grinder comes with overload protection.

• 3-year limited warranty and one-year free service.

Cons

• Battery life is not the greatest.

Chemical Tungsten Electrode Sharpeners

The chemical sharpening method is pointing tungsten electrodes using chemical compounds. The tungsten is heated by shorting it against any piece of metal or by any external heating source before dipping in the compound.

The chemical is a strong alkaline that dissolves the hot tungsten. The chemical reaction between the tungsten and compound creates additional heat to keep the tungsten hot. The tungsten rod is then cooled and cleaned before using it.

You need to be careful when using this grinding method of the fumes that come out of the process that may affect your health.

Best Chemical Sharpener

Dynaflux Tungsten Electrode Sharpener

Dynaflux tungsten electrode sharpener is an alternative to tungsten grinding. Chemically mills and pointing pure, thoriated, ceriated, and lanthanated tungsten.

Taking an average time of approximately one minute to re-point tungsten at the work station.

Compared to traditional sharpening methods, chemical re-pointing extends tungsten life by 400%.

Pros

• A simple way of grinding tungsten.

• Gives a smooth sharp needlepoint.

• Works with all tungsten types.

• The process does not require any tools or power supply.

• Takes approximately one minute to re-point tungsten.

• Extends tungsten life by 400%.

• A low-cost way of grinding tungsten.

Cons

• The chemical reaction creates a lot of fumes and ejects some molten material.

Our final verdict

In this article, we have tried to give a complete overview of tungsten electrodes sharpening and how it has a significant influence on the result of TIG welding.

We have also recommended and reviewed the best grinders and sharpeners for different uses to aid you in making the best purchase choice.

Sharpening tungsten electrodes is not a difficult task, and with one of the above tools, you can accomplish the task easily and super-fast.

You only need to remember the tips and tricks we discussed, especially clean grinder, lengthwise grinding, and proper bevel angle, and you are set to go for your next extraordinary weld bead.